How much does a solar frame film laminating machine cost?

The cost associated with a solar frame film laminating machine varies widely based on several factors such as the manufacturer, specifications, production capacity, and additional features, with price ranges typically spanning from $10,000 to over $200,000. For higher-end machines, particularly those designed for industrial-scale production, costs can escalate significantly, depending on the technological innovations included, like automation and enhanced efficiency. Moreover, maintenance and operational costs play a critical role in the total investment, which should not be overlooked when calculating the overall expenditure.

1. UNDERSTANDING SOLAR FRAME FILM LAMINATING MACHINES

The solar frame film laminating machine serves a critical function in the photovoltaic manufacturing process. These machines apply protective films to solar panels, ensuring durability and enhancing performance. The choice of laminating technology impacts both the quality of the finished product and the cost associated with the machinery. Traditional laminating techniques often require manual handling, leading to high labor costs and increased chances of defects, while automated systems promise efficiency and consistency.

Laminating processes involve various parameters such as temperature, pressure, and time, which need to be finely tuned for optimal results. As a result, a thorough understanding of these parameters becomes essential for successful operation. Notably, investment in high-quality laminating machines is crucial, as subpar equipment may lead to production inefficiencies, increased failure rates, and ultimately higher long-term costs.

2. FACTORS INFLUENCING THE PRICE

Several determinants significantly influence the pricing of solar frame film laminating machines. First, the specifications of the equipment greatly determine its cost. Machines designed for high-volume production often include advanced features like automatic feeding systems and integrated quality control mechanisms. Second, the manufacturer’s reputation also plays a pivotal role. Established brands with a track record for reliability typically command higher prices due to the assurance they provide in terms of machinery performance and after-sales support.

Furthermore, geographical location can affect pricing structure. Prices may vary based on shipping, tariffs, and availability of local suppliers. For example, acquiring equipment from overseas manufacturers might incur additional freight and import duties, thus increasing the overall cost. Warranty packages and after-sales service agreements are other factors that can add to the cost but can also provide substantial value in terms of ongoing machine maintenance and support.

3. COMPARING TYPES OF MACHINES

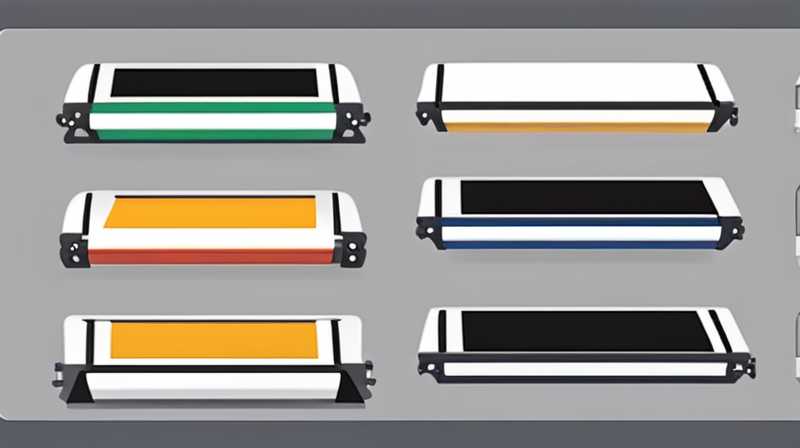

Varying types of solar frame film laminating machines exist in the market, each with distinct functionalities, operational methodologies, and price points. First, manual laminators offer a cost-effective entry point for small businesses or startups, though they demand more labor and entail slower production speeds. These machines generally possess simpler design structures and can start at prices as low as $10,000, making them attractive for smaller-scale operations or experimental setups.

Next, semi-automated systems bring a middle-ground solution by automating specific tasks while still requiring some manual intervention. Priced typically between $30,000 and $100,000, semi-automated machines enhance production efficiency and reduce labor costs while maintaining relatively high levels of quality. Meanwhile, fully automated laminating machines represent the pinnacle of solar frame film technology. These systems allow for continuous operation with minimal human oversight, featuring sophisticated algorithms for quality assurance and output analytics. Though they are significantly more expensive, ranging from $100,000 to over $200,000, the long-term savings from reduced labor and improved efficiency can justify the initial investment.

4. ASSESSING RETURN ON INVESTMENT

Evaluating the financial implications of investing in a solar frame film laminating machine involves a nuanced approach. Return on Investment (ROI) should factor in not only the initial acquisition cost but also operational expenses, production yields, and potential revenue generated from the solar panels manufactured. Enhancing production capacity through proper machinery can lead to increased sales opportunities, especially in a market where demand for renewable energy solutions is on the rise.

Moreover, quality plays a crucial role in establishing brand reputation and customer loyalty. Investing in reliable, efficient equipment that minimizes defects can significantly reduce costs associated with warranty claims and product returns. Given that customer satisfaction directly correlates with a company’s bottom line, the long-term benefits of investing in high-quality laminating machines often outweigh the higher upfront costs. Organizations must also consider energy efficiency and maintenance costs when calculating ROI, as these will greatly impact overall profitability in the long run.

5. MAINTENANCE AND OPERATIONAL COSTS

The overall budget for a solar frame film laminating machine should also encompass ongoing maintenance and operational costs. Preventive maintenance is essential to ensure the longevity and optimal performance of the machine. Regular inspections and timely replacement of wear-and-tear components can prevent larger, costly breakdowns. Companies must allocate funds for ongoing training for their personnel, as skilled operators are crucial to maximizing the machine’s potential, ensuring that the machinery operates at peak efficiency while adhering to safety standards.

Additionally, energy consumption must be evaluated, especially in high-capacity machines that require significant power to operate. Manufacturers should consider investing in energy-efficient models that minimize operational costs in the long run. Furthermore, as the technology behind solar frame laminating machines evolves, maintaining compatibility with the latest innovations may involve additional costs related to software updates or hardware retrofits.

FAQs

WHAT IS THE AVERAGE COST FOR A SOLAR FRAME FILM LAMINATING MACHINE?

The average cost of a solar frame film laminating machine can vary significantly depending on several factors. Basic models start around $10,000, which typically feature simple manual operations suited for smaller businesses. More advanced semi-automated machines can range from $30,000 to $100,000, designed to enhance productivity and reduce labor costs. Finally, fully automated systems are available for larger-scale operations and can exceed $200,000. These higher-end machines are capable of delivering consistent, high-quality results with a lower risk of human error. Considering these variations, businesses must assess their production needs and budget availability to determine the most suitable option.

ARE THERE COSTS OUTSIDE OF THE INITIAL MACHINE PURCHASE?

Yes, costs extend beyond the initial investment in a solar frame film laminating machine. Operational costs, such as labor, energy consumption, and routine maintenance, significantly contribute to the total expenditure. Companies must also consider the cost of potentially necessary modifications or upgrades as technology advances. Furthermore, raw materials and films used in the laminating process must be factored into the overall budget, as different materials may differ in price and availability, affecting cost stability. Training for personnel to operate and maintain the machinery is another crucial expense that should not be overlooked, ensuring that staff have the requisite skills to minimize downtime and maximize operational efficiency.

WHAT FACTORS SHOULD I CONSIDER WHEN PURCHASING A SOLAR FRAME FILM LAMINATING MACHINE?

Several critical aspects warrant consideration when purchasing a solar frame film laminating machine. First and foremost is understanding your production capacity requirements, as this determines the machine type and whether to opt for manual, semi-automated, or fully automated systems. Budget constraints play an essential role, as companies need to balance the initial investment with potential long-term savings from efficiency and durability. Additionally, the reputation of the manufacturer should be evaluated, as established brands often provide better support and warranty options. Maintenance cost, energy consumption, and operator training needs must be factored into the decision-making process, as these elements contribute significantly to the total cost of ownership.

The investment in solar frame film laminating machinery should be viewed not merely as a purchase but as a strategic decision with far-reaching implications for a company’s operational success and sustainability in the evolving renewable energy market. Balancing initial costs with potential return on investment is crucial for maximizing profitability while ensuring high-quality production levels. Furthermore, understanding how maintenance, energy efficiency, and training for personnel factor into the operational landscape can provide valuable insights into overall efficiency. In summary, careful consideration of these various dimensions will be paramount for businesses looking to navigate the complexities of solar frame film laminating machinery successfully.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-a-solar-frame-film-laminating-machine-cost/