A pneumatic energy storage machine in Zhengzhou typically incurs a cost that fluctuates due to several determinants such as 1. Size and capacity, 2. Manufacturer reputation, 3. Technological features, 4. Installation requirements. These machines can range from tens of thousands to several million RMB. For instance, small-scale systems designed for limited applications may be priced lower, while large, sophisticated units that serve industrial needs can reach premium price points. Notably, installation and maintenance costs should also be included when assessing the overall expenditure. Factors such as operational efficiency and durability further influence a buyer’s investment. Exploring local suppliers will yield specific pricing tailored to individual requirements. In the rapidly evolving market for energy solutions, it’s prudent to analyze both upfront and long-term costs to make an informed decision.

1. UNDERSTANDING PNEUMATIC ENERGY STORAGE

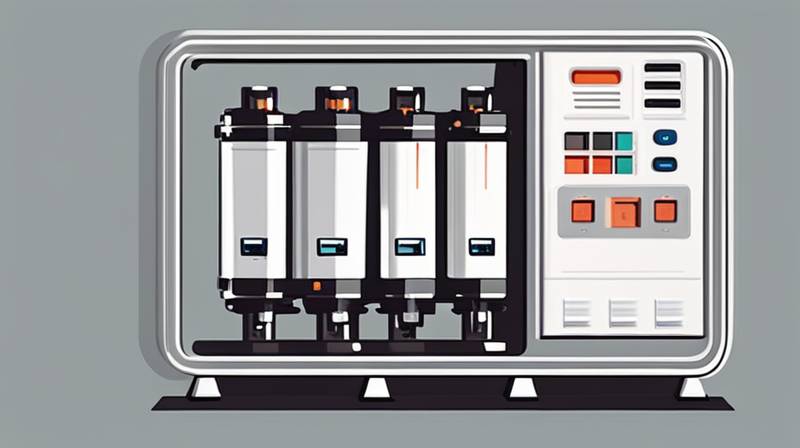

Pneumatic energy storage systems harness compressed air to store energy, facilitating a crucial approach to energy management. The fundamental workings of these machines involve compressing air, which is then stored in high-pressure tanks until energy is required. When demand arises, the stored air is released, driving turbines or other mechanisms to generate power. This technology provides an appealing solution for balancing energy loads, particularly in scenarios with intermittent renewable energy sources.

One salient advantage of this system lies in its environmental impact. Compared to fossil fuel-based energy storage solutions, pneumatic systems utilize air as the storage medium. The compression process employed does generate emissions, but the overall ecological footprint is minimized, especially when integrated with clean energy systems. Moreover, these machines can significantly enhance grid stability, allowing for more renewable energy integration into existing infrastructures.

2. FACTORS IMPACTING COST

Several pivotal elements influence the pricing of pneumatic energy storage machines. 1. Size and capacity, 2. Technical specifications, and 3. Market dynamics are crucial in determining the overall cost.

Sizing a pneumatic energy storage machine appropriately not only meets the specific energy requirements but also impacts the capital expenditure. Larger systems naturally come with elevated costs due to their increased materials and engineering complexities. However, they also provide economies of scale that might justify the investment. Manufacturers often provide various configurations, empowering potential buyers to select the most suitable option for their operational needs.

Technical specifications are equally significant. Systems incorporating advanced automation, sophisticated control mechanisms, and greater operational efficiency command higher prices. The integration of sensors and smart technology can enhance performance, but potential buyers must weigh these benefits against the associated costs. Additionally, the materials used in construction, such as robust alloys or specialized composites, can significantly influence the machine’s pricing structure.

3. INSTALLATION AND MAINTENANCE EXPENSES

After the initial purchase, one cannot overlook the costs tied to installation and ongoing maintenance. Proper installation of a pneumatic energy storage machine necessitates careful engineering and skilled labor, which can contribute substantially to total expenses. The installation environment can also dictate costs, especially in unique or challenging settings.

Ongoing maintenance is critical for ensuring optimal performance and longevity. Regular checks, servicing, and potential repairs must be factored into the operational budget. Expert maintenance specialists are often required to effectively manage these systems. Such professionals ensure not only that machines run efficiently but also that they comply with regulatory standards, which can further incur costs depending on local compliance requirements.

Moreover, with the advancements in technology, some manufacturers offer extended warranties or service packages. These options provide peace of mind but represent an additional expense that should be assessed in the overall budget for a pneumatic energy storage system.

4. MARKET COMPARISONS

A thorough analysis of local suppliers and manufacturers in the Zhengzhou region is pivotal for individuals or companies considering a pneumatic energy storage machine. Vendors exhibit varying pricing strategies, influenced by factors like market saturation and competition levels. Identifying the primary players in the market enables a prospective buyer to leverage competitive pricing and negotiate terms better.

Reviews and case studies of existing installations provide valuable insight into performance and reliability. Engaging with previous clients can yield firsthand information on how machines perform under real-world conditions. Further, visiting operational sites can help prospective buyers gauge the scale and effectiveness of the technology.

Additionally, exploring international manufacturers might uncover unique technological advancements or competitive pricing. However, one must also evaluate the cost of transportation and customs duties for imported machines. A comprehensive analysis of both local and international options provides an informed baseline for decision-making, ensuring that the chosen system aligns precisely with the buyer’s needs.

FREQUENTLY ASKED QUESTIONS

WHAT WARRANTY OPTIONS ARE AVAILABLE FOR PNEUMATIC ENERGY STORAGE MACHINES?

Generally, warranties for pneumatic energy storage machines can vary significantly based on the manufacturer, model, and specific terms of service. Most manufacturers offer a standard warranty covering parts and sometimes labor for a limited time, usually ranging from one to three years. Extended warranties may also be available at an additional cost, offering coverage beyond the standard period.

Warranties often include provisions for defects in materials and workmanship, ensuring that buyers are protected against unexpected failures during the coverage duration. It’s essential to carefully scrutinize warranty details, as conditions such as proper maintenance, usage limitations, and repair eligibility can affect the enforceability of such guarantees.

Manufacturers may also provide service packages that include regular maintenance and inspection. Such packages can encompass routine check-ups that prevent issues before they arise, complementing the warranty and providing additional peace of mind for owners.

HOW DO PNEUMATIC ENERGY STORAGE SYSTEMS COMPARE TO OTHER ENERGY STORAGE SOLUTIONS?

When comparing pneumatic energy storage systems to alternatives like batteries and pumped hydro storage, several factors come into play. Firstly, pneumatic systems can handle larger power scales more efficiently and have the ability to discharge high volumes of air quickly. This can be particularly advantageous for large industrial facilities with substantial energy demands.

Additionally, pneumatic storage generally has a longer operational lifespan compared to chemical batteries, which require periodic replacements. Since air serves as the storage medium, concerns related to material degradation seen in batteries are diminished. Also, pneumatic systems can integrate with renewable energy sources more seamlessly, optimizing their performance during renewables’ peak production times.

However, one must consider environmental implications. Though pneumatic systems are more eco-friendly than fossil fuel-based solutions, they are not devoid of challenges. Efficiency rates and energy losses during compression and decompression cycles must be evaluated against other options. Therefore, a comprehensive analysis of facility requirements and energy use patterns is essential to make a well-informed choice between these storage technologies.

WHAT IS THE AVERAGE PAYBACK PERIOD FOR INVESTING IN A PNEUMATIC ENERGY STORAGE SOLUTION?

Determining the average payback period for investments in pneumatic energy storage is contingent upon multiple considerations. Factors such as initial investment cost, operational savings, and maintenance expenditures contribute significantly to the return on investment timeline. Typically, businesses can expect payback periods ranging from three to eight years, though this can extend based on specific use cases.

Operational savings arise from improved energy efficiency and capability to lower utility costs, especially during peak demand periods. By utilizing stored energy during these times instead of purchasing from the grid, facilities can accrue substantial savings over time. In some regions, governmental incentives and subsidies for adopting renewable energy technologies may enhance return rates, shortening the payback duration.

Accurate forecasting of energy consumption patterns and operational efficiencies is critical in defining a realistic payback period. Organizations should conduct extensive financial assessments, factoring in all potential costs and savings, to ascertain the best strategies for maximizing recovery on their energy investment.

The intricate dynamics associated with pneumatic energy storage machines and their cost implications necessitate a thorough investigation. Factors like size, capacity, and technological specifications play a crucial role in determining expenses. Additionally, ongoing maintenance and installation costs contribute significantly to total investment. Understanding market alternatives, supplier offerings, and the correlations between investment and returns is imperative for stakeholders. With comprehensive analysis and careful evaluation, organizations can effectively navigate the complexity of energy storage solutions while optimizing their value proposition. This meticulous approach ensures organizations uphold resilience in their energy strategies, paving the way for sustainable practices in a constantly evolving energy landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-a-pneumatic-energy-storage-machine-cost-in-zhengzhou/