How much air pressure is the accumulator airbag filled with?

1. Accumulator airbags typically maintain air pressure between 90 and 140 psi, which is crucial for their operation and efficiency in enhancing vehicle safety systems. 2. The pressure within the unit can be influenced by various factors, including temperature and the manufacturer’s specifications, meaning exact values may vary across different airbag designs. 3. Understanding the precise pressure range is essential for automotive engineers and safety professionals, as it impacts the deployment speed and overall effectiveness during a collision event. 4. Maintaining accurate pressure levels is crucial for the function and reliability of the accumulator airbag, which must be assessed regularly for operational safety.

1. ACCUMULATOR AIRBAGS: AN INTRODUCTION

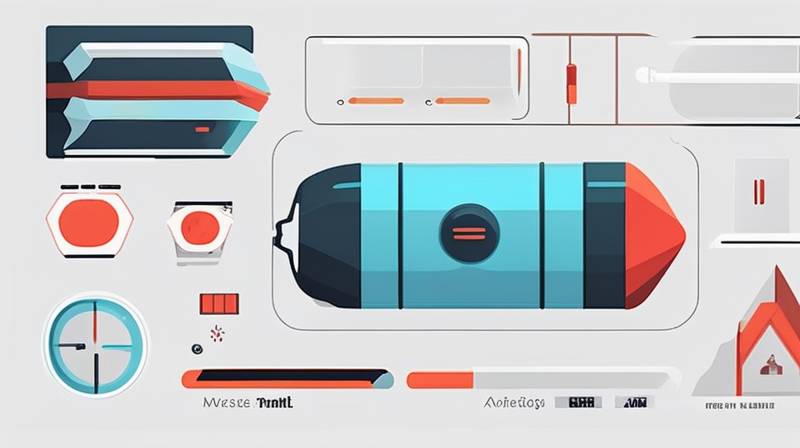

Accumulator airbags represent an innovative advancement in automotive safety, designed to act as a supplementary tool in the event of a collision. These airbags are distinct from conventional airbags due to their structure and mechanisms, which allow for compressed air storage until deployment. Understanding how these systems operate requires familiarity with their inner workings and the role of air pressure within the units.

The establishment of optimal air pressure within accumulator airbags is paramount to ensuring their effectiveness when deployed. The different variables impacting air pressure must be considered as this helps to enhance a vehicle’s active and passive safety features. Furthermore, design specifications and temperature fluctuations can alter pressure levels in unpredictable ways. Such factors must be meticulously monitored to ensure the airbag system performs effectively in emergencies.

2. AIR PRESSURE RANGE IN ACCUMULATOR AIRBAGS

Accumulating evidence suggests that the air pressure range maintained in accumulator airbags is typically between 90 and 140 psi. This range is critical for ensuring that the airbag deploys quickly and efficiently upon impact. The air pressure must be high enough to provide sufficient force to inflate rapidly but low enough to avoid premature deployment and subsequent failures.

Factors that influence the specified pressure range include the materials used in the bag’s construction and the overall design of the airbag system. Material characteristics like elasticity and tensile strength directly influence how the airbag performs under different pressure scenarios. An airbag must not only withstand high pressures during operation but also face varying temperatures that can cause fluctuations in pressure.

3. FACTORS INFLUENCING AIR PRESSURE

A multitude of factors can influence the air pressure within accumulator airbags. Temperature fluctuations are among the most significant contributors, as they directly affect air density. As temperatures rise, gases expand, and conversely, they contract in cooler surroundings. This results in pressure variations that can affect an airbag’s performance during a critical event.

Manufacturers develop specific guidelines to mitigate these variabilities, outlining recommended pressure ranges and maintenance schedules for optimal performance. Regular checks and maintenance are necessary to assess the air pressure levels routinely. Engineers also consider regional climates and vehicle usage conditions, adjusting the designs accordingly to accommodate environmental influences.

4. ENSURING OPTIMAL PERFORMANCE AND SAFETY

To maintain the integrity and effectiveness of accumulator airbags, it is crucial to prioritize routine checks and maintenance of the air pressure levels. Vehicles equipped with this safety feature should adhere to manufacturer guidelines for service intervals, ensuring timely assessments of air pressure and system integrity.

Furthermore, technological advancements within the automotive industry are gradually evolving to enhance airbag functionality. Many modern systems now involve sensors that can continuously monitor air pressure, providing real-time adjustments during operation. Vehicle owners can be proactive in preventing potential failures by becoming familiar with their vehicle’s airbag system, understanding the indicators of low pressure or system inefficiencies, and addressing these concerns promptly.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE PURPOSE OF AN ACCUMULATOR AIRBAG?

Accumulator airbags serve as a secondary safety mechanism in vehicles, designed to deploy rapidly in the event of a collision. Their primary purpose is to cushion occupants during impact, thereby minimizing injury risks. The airbag inflates using compressed air, and its deployment is triggered by sensors that detect collision forces. Understanding both the intended function and operational dynamics is crucial for vehicle design and occupant safety.

HOW DO TEMPERATURE FLUCTUATIONS AFFECT AIR PRESSURE IN ACCUMULATOR AIRBAGS?

Temperature fluctuations can significantly impact the pressure within accumulator airbags. As temperatures increase, the volume of the air expands, leading to higher pressure levels. Conversely, colder temperatures can result in contractions, diminishing the pressure. Consequently, manufacturers must account for these variations in their safety systems. Vehicle owners should be aware of how external conditions might influence airbag performance, ensuring regular maintenance checks are performed to mitigate any risks.

WHAT MAINTENANCE IS REQUIRED TO ENSURE AIR PRESSURE STABILITY IN ACCUMULATOR AIRBAGS?

To guarantee air pressure stability in accumulator airbags, regular maintenance and inspections are essential. Manufacturers typically provide guidelines on how often these systems should be checked, often recommending assessments twice a year. During these inspections, technicians check for leakage, evaluate the integrity of the airbag’s materials, and ensure that the air pressure remains within recommended limits. Keeping accurate records of these inspections aids in identifying potential problems before they evolve into safety hazards.

Understanding the precise air pressure maintained within accumulator airbags is vital for ensuring their reliability and effectiveness in enhancing passenger safety. The range of 90 to 140 psi that these airbags typically operate within is dictated by multiple factors, including temperature variations and construction materials. It becomes imperative for automotive professionals and vehicle owners alike to recognize the importance of regular maintenance and adherence to manufacturer guidelines to guarantee optimal performance. As technology continues to advance, the automotive industry is adapting its approach to ensure greater safety through innovative designs, real-time monitoring systems, and improved materials. Continuous education on these systems will foster a more profound appreciation for automotive safety features and their critical role during emergencies. Ultimately, staying informed and vigilant regarding air pressure levels in accumulator airbags can significantly reduce the risk of malfunctions and ensure the utmost protection for vehicle occupants.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-air-pressure-is-the-accumulator-airbag-filled-with/