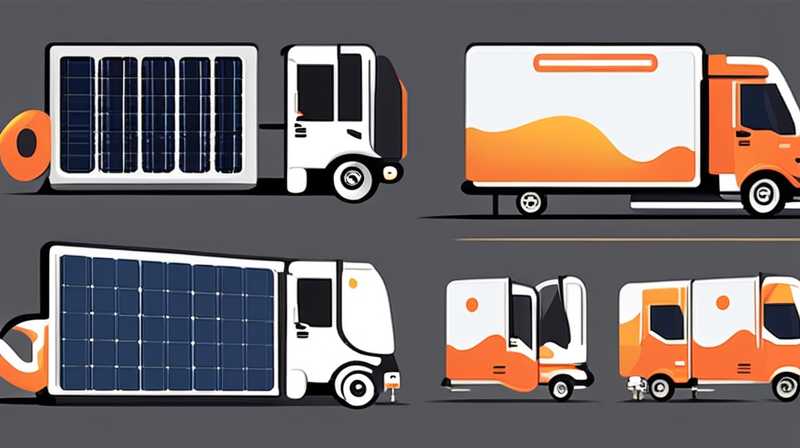

1. The solar panel on the bed truck typically has a capacity ranging from 100 to 400 watts, depending on the size and type of the panel. Several factors influence this capacity, including the intended use, space available, and energy requirements of the truck. The most commonly utilized panels are monocrystalline and polycrystalline solar cells, which offer distinct advantages that will be discussed in-depth. Given the versatility of bed trucks, various configurations are available to accommodate diverse needs, such as powering auxiliary lighting, refrigeration units, or leisure electronics.

1. UNDERSTANDING SOLAR PANELS FOR BED TRUCKS

Solar technology has seen significant advancements over recent years, leading to growing adoption in various applications, including bed trucks. With the increasing demand for sustainable energy solutions, the integration of solar panels into mobile units has become a cutting-edge trend. Solar panels on bed trucks provide an indispensable alternative energy source, allowing users to generate clean power during their travels. This section will elucidate the fundamentals of solar energy systems and how they operate within the context of a bed truck.

Solar panels operate based on photovoltaic (PV) technology, which converts sunlight into electricity. This process begins when light photons hit the solar cells embedded within the panels, creating direct current (DC) electricity. The generated DC electricity is then directed to an inverter, converting it into alternating current (AC) electricity suitable for desiring appliances and devices. The scale of wattage produced can vary significantly based on the size of the installation and the model of solar panels employed.

In the context of bed trucks, the integration of solar panels presents multiple advantages. These include decreased reliance on fossil fuels, reduced environmental impact, and the capacity for energy independence on long trips. Furthermore, utilizing solar energy can lead to substantial long-term savings on fuel and operational expenses. When evaluating a solar panel setup for a bed truck, understanding the various options available allows for a tailored approach focusing on specific energy needs.

2. FACTORS INFLUENCING WATTAGE CAPACITY

Several key elements determine the wattage capacity of solar panels installed on bed trucks. These variables include panel type, efficiency ratings, panel size, and the intended purpose of the solar setup. Grasping how these factors impact wattage is essential for making informed decisions during installation and configuration.

Panel type plays a crucial role in determining output performance; solar panels generally fall into three primary categories: monocrystalline, polycrystalline, and thin-film. Monocrystalline panels boast the highest efficiency and power output because they are made from a single crystal structure. As a result, these panels tend to produce more electricity from the same surface area compared to their counterparts. On the other hand, polycrystalline panels are composed of multiple crystal structures, generally making them less efficient but more cost-effective. Thin-film panels, while lightweight and flexible, exhibit lower efficiency, making them suitable for specific applications but not always ideal for power generation on bed trucks.

Efficiency ratings further impact the amount of power generated. Higher efficiency ratings signify that a panel converts a larger percentage of sunlight into electricity, thus boosting overall wattage capacity. Using advanced technologies, some manufacturers produce solar panels with efficiency ratings exceeding 20%, which can result in more power output in compact installations.

3. ENERGY REQUIREMENTS OF BED TRUCKS

Evaluating the energy requirements is integral when determining the appropriate wattage capacity for solar panels on bed trucks. Various components, such as communication devices, lighting, or entertainment systems, may necessitate power supply. Adequately understanding these needs will facilitate more effective utilization of solar energy and enhance the overall efficiency of the system installed.

One important consideration involves the cumulative wattage needed for all devices that will utilize solar power. Calculating each device’s wattage will help determine the total energy consumption. For example, if a truck’s lighting system requires 60 watts, while the refrigerator demands another 120 watts, the total consumption will amount to 180 watts. This figure provides a solid baseline to proceed with selecting the appropriate solar panel wattage to meet or exceed this energy demand.

Furthermore, assessing daily energy use is crucial for maintaining a reliable power supply. Establishing an energy budget and estimating how long devices will be in operation helps clarify the solar power system’s requirements. By doing this, an owner can forecast whether additional panels or supplementary battery storage will be needed to ensure a steady flow of electricity.

4. INSTALLATION CONSIDERATIONS

When opting for solar panel installation on bed trucks, multiple factors come into play, influencing how well the system performs. Space, alignment, and structural integrity are essential considerations ensuring efficient energy capture and optimal functioning.

Space availability is a significant concern. Bed trucks come in various dimensions, and the area dedicated to solar panels will limit potential wattage capacity. Owners must assess the suitable locations for panel installation; flat surfaces on the truck’s structure usually allow for better mounting and positioning. The optimal alignment and orientation of panels will also play a significant role in maximizing sunlight exposure. Panels should ideally face south (in the northern hemisphere) to capture maximal solar energy throughout the day.

Moreover, the structural integrity of the truck bed is paramount to ensure safety and reliability during panel operation. Mounting hardware must be secure enough to withstand highway speeds and weather conditions. Adequate insulation and waterproofing measures can help eliminate complications arising from harsh environments, which is particularly relevant for long-term use in rugged conditions.

5. BATTERY STORAGE AND INVERTERS

Battery storage systems are often integrated with solar panel setups to store excess energy generated during sunlight hours. This allows for a consistent power supply even when the sun isn’t shining. The capacity of these battery systems is essential, as it affects how much energy can be stored for later use.

The capacity of a battery system is typically measured in amp-hours (Ah), and selecting the right size to match the solar array’s output ensures sufficient energy availability. After calculating energy needs and estimated output from the panels, truck owners can select batteries capable of storing that energy effectively. Lithium-ion batteries offer advantages over traditional lead-acid batteries, including lighter weight, higher energy density, and longer lifespans.

Inverters, similarly, act as crucial components within the complete solar power framework. They convert the direct current produced by the solar panels into alternating current used by most household appliances. Selecting a quality inverter that can handle peak load demands is vital for seamless functionality. Furthermore, an inverter’s efficiency rating is as important as that of solar panels, influencing how much energy is lost during the conversion process.

6. MAINTAINING SOLAR PANELS

Regular maintenance is essential for ensuring the longevity and efficiency of solar panels mounted on bed trucks. Environmental factors such as dust, debris, and grime can hinder solar absorption, resulting in diminished performance. Routine cleaning and inspections are paramount for maintaining optimal output.

Periodic cleaning of solar panels contributes significantly to their efficiency. Dust accumulation may reduce the amount of sunlight reaching the cells, substantially diminishing power production. Depending on environmental conditions, cleaning may be necessary twice a year. Using water and a soft cloth will help eliminate dirt without damaging the panel structure.

Also, carrying out routine inspections will help identify potential issues early. Checking for cracks, loose wiring, or damaged components allows truck owners to address problems before they escalate, ensuring sustained operational efficiency. Consistent monitoring of the system’s performance through data logging or even casual observations can help owners stay informed about potential drops in energy production, enabling quick corrective measures.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE AVERAGE WATTAGE OF SOLAR PANELS FOR BED TRUCKS?

The wattage of solar panels intended for installation on bed trucks typically falls between 100 to 400 watts. However, many factors can influence this wattage, including the specific energy needs of the truck and the available installation space. Monocrystalline panels generally have higher wattage outputs compared to polycrystalline options due to their improved efficiency levels. Consequently, choosing the appropriate wattage is essential for meeting the electrical demands of the bed truck, whether for powering lights, communication devices, or fridges.

HOW DO I DETERMINE WHAT SIZE SOLAR PANEL SYSTEM I NEED FOR MY BED TRUCK?

Determining the size of a solar panel system for a bed truck necessitates evaluating the energy consumption of devices intended for use. A good starting point is to tally up the wattage required for all devices. Daily energy usage can also help clarify how much energy needs to be generated, taking into consideration hours of operation. Additionally, owners should consider their desired level of autonomy and whether energy storage is necessary. Solar panel systems can typically be customized, allowing for tailored configurations that meet specific requirements efficiently.

DO I NEED A BATTERY SYSTEM WITH MY SOLAR PANELS ON A BED TRUCK?

In most cases, integrating a battery system with solar panels greatly enhances overall energy reliability. Batteries facilitate the storage of excess energy generated during daylight hours, allowing for consistent power availability at night or during cloudy weather. Without a battery system, relying solely on direct solar energy may lead to fluctuations in power availability. The need for battery storage will depend on the specific requirements of the truck owner, so evaluating energy demands is crucial when deciding whether to include this component in the solar power setup.

Solar panels on bed trucks represent a sustainable energy solution, providing crucial benefits to users while reducing carbon footprints. By understanding wattage capacity, energy requirements, installation considerations, and maintenance practices, truck owners can make informed decisions that enhance the functionality of their solar-powered systems. Furthermore, focusing on factors such as battery storage and inverter selection will contribute to creating a robust energy infrastructure, ultimately maximizing benefits and efficiency. With the increasing reliance on green technologies, integrating solar energy into bed trucks stands as a forward-thinking approach that not only meets contemporary energy demands but also paves the way towards a more sustainable and eco-friendly future. Such arrangements enhance the overall experience of users while empowering them with independence from conventional energy sources, shaping a more resource-efficient world. Sustainable energy solutions, like solar panels, ensure cost savings while concurrently acting in favor of the environment, thereby addressing both energy efficiency and ecological responsibility.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-watts-does-the-solar-panel-on-the-bed-truck-have/