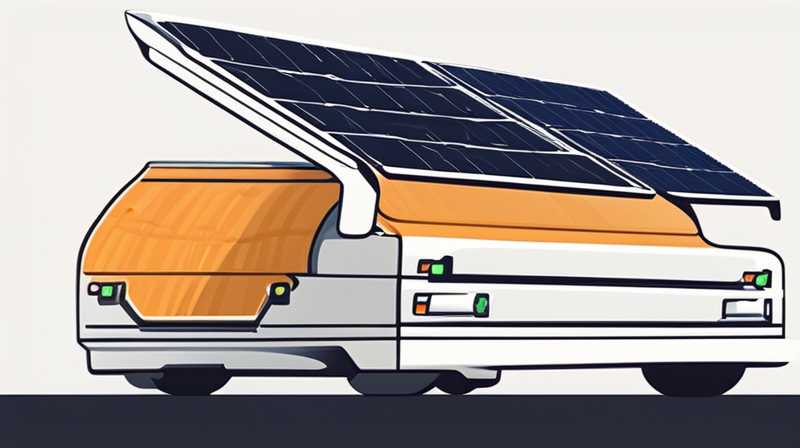

To determine how many volts are needed to purchase solar panels for a bed truck, three primary factors should be considered: 1. Voltage requirements based on the truck’s electrical system, 2. The power consumption of appliances, 3. The capacity of the solar panels available.

1. Voltage requirements based on the truck’s electrical system: It is crucial first to assess the truck’s voltage specifications, as different vehicles may operate on different systems (12V or 24V). Generally, most pickup trucks function on a 12V system, which aligns with standard RV and solar panel setups. This ensures that any solar system installed operates efficiently and without complications. Often, truck owners must choose solar panels that are compatible with their vehicle’s electrical characteristics, including voltage regulation systems needed for safety.

2. The power consumption of appliances: Evaluating the power consumption of appliances intended for use in the truck is essential. Different devices draw varying amounts of current—ranging from small LED lights to larger systems like refrigerators or inverters. Calculating the total wattage these devices will need is fundamental in deciding the solar panel requirements. Multiplying the sum of these devices’ power needs by the total hours they will be on will provide a clearer picture of total daily energy consumption and how much solar capacity must be integrated.

3. The capacity of solar panels available: The specific models of solar panels considered will also play a significant role in determining how many are necessary. Solar panels come with different wattage outputs, typically ranging from 100W to 400W. By factoring in the rated output of the solar panels, the total energy consumption can then be effectively matched to define the quantity of panels required. This analysis will not only encompass the correct number of units but also factor in shadowing, tilt angles, and solar inefficiency, ensuring a robust energy generation solution.

A DETAILED ANALYSIS OF VOLTAGE REQUIREMENTS FOR SOLAR PANELS

Understanding Truck Voltage Systems

Electric systems in trucks commonly utilize 12V or 24V configurations, largely determined by the battery arrangement. Most light-duty trucks align with the 12V system, while larger vehicles typically operate on 24V systems. With a 12V system, wiring solar panels and other peripherals directly becomes simpler, enabling smooth energy consumption management.

Understanding a truck’s electrical architecture is critical when designing a solar solution. Neglecting to match solar output directly to these voltage specifications can yield performance setbacks. Installing a solar panel designed for a 24V system onto a 12V setup would not produce the desired energy output. Therefore, ensuring the solar panel voltage matches or complements the truck’s electrical setup is indispensable.

Compatibility With Energy Storage

While voltage requirements dictate panel selection, they also highlight the necessity for associated storage solutions, such as batteries. Integrating a proper battery bank to store surplus energy from solar panels further optimizes the power supply for the truck’s operation. Finding the right combination of voltage specifications for both solar panels and batteries can lead to enhanced energy efficiency.

Using charge controllers and inverters compatible with the truck system is vital for maintaining optimal function, safety, and extending the life of both solar installations and the vehicle’s electrical components. Understanding and matching these elements to the truck’s electrical system lays the foundation for a successful solar energy implementation.

EVALUATING POWER CONSUMPTION FOR ACCURATE PANEL COUNT

Assessing Daily Power Needs

A clear understanding of daily power consumption involves documenting all electrical components used in the truck. Owners should compile a list of all devices, assess wattage needs, and create calculations based on how long each will operate.

This comprehensive evaluation will reveal total wattage requirements against time, resulting in total daily power consumption. For instance, if the truck requires 200W continuously for eight hours, this translates to 1,600Wh per day. Having this numerical value significantly aids in discerning how many panels are necessary to fulfill such requirements.

Determining Solar Panel Outputs

Given the substantial variation of panel output (between 100W and 400W), solar system designers must draw up a comparison chart to ascertain how many panels are required to meet the daily power needs assessed earlier. With multiple panels contributing to the overall wattage, the calculations can diverge depending on weather conditions, available sunlight, and the angle of solar installations.

It is important to remain conservative in power estimates, as factors like shading on panels or seasonal variations can lead to decreased output. Rounding up the desired output by including extra capacity not only ensures consistent power supply but also accounts for unforeseen circumstances which may disrupt energy generation.

EXPLORING SOLAR PANEL CAPACITY

Solar Panel Wattage Considerations

After establishing energy needs, assessing solar panel specifications is the next critical step. Solar panels commonly provide wattage outputs between 100W to 400W; higher wattage panels produce more energy, thereby reducing the overall number needed.

For instance, if energy requirements total 1,600Wh per day, and developers opt for 200W panels, calculations yield needing a minimum of eight panels to fulfill daily consumption. Conversely, higher wattage panels reduce this number, showcasing the interplay between wattage ratings and required quantities.

Weather or Seasonal Adjustments

Beyond raw calculations, understanding potential declines in solar generation due to weather or obstructive trees is essential. During overcast periods, panel outputs might diminish significantly, prompting owners to reconsider the total number of panels.

To counteract seasonal impacts, professionals often recommend an energy reserve or over-production. Implementing higher output solar designs ensures a sustainable energy supply, maintaining functionality throughout diverse weather scenarios.

FINANCIAL INVESTMENT AND RETURN ON SOLAR SYSTEMS

Cost Analysis of Solar Panel Installation

Even before making decisions based on power needs, potential buyers must evaluate the financial investments associated with solar installations. The initial capital outlay varies significantly based on the solar market conditions and specific system configurations.

When assessing upfront costs, elements such as panel manufacturing, installation services, and hardware components come into play. Potential owners need to weigh each of these segments to determine if the overall price is justifiable compared to the long-term energy savings achieved.

Return on Investment Calculations

Beyond immediate expenses, considering the return on investment based on energy savings is always paramount. Comparison calculations concerning fuel costs versus solar energy generation can yield insights into the long-term benefits of solar integration.

The life expectancy of solar systems, generally in the 20-30 year range, also enhances their appeal. If a solar installation significantly reduces fuel consumption, these savings can accrue significant financial returns over time, effectively justifying the initial financial outlay.

FREQUENTLY ASKED QUESTIONS

HOW DO I DETERMINE MY TRUCK’S VOLTAGE SYSTEM?

To ascertain the specific voltage system utilized in a truck, look towards owner manuals or contact the manufacturer directly. Most standard trucks feature 12V, while larger or heavy-duty vehicles may operate on a 24V configuration. Confirming this detail ensures accurate compatibility between the solar system and the vehicle’s electrical architecture, optimizing efficiency and preventing electrical complications.

WHAT APPLIANCES CAN I POWER WITH MY TRUCK SOLAR SYSTEM?

The diversity of appliances powered by a truck’s solar configuration is extensive. Owners often harness energy for essentials like lights, refrigerators, and battery chargers or inverters. It’s important that these devices’ total wattage falls within the limits of the installed solar system. Each device’s specifics must be accounted for to ensure that energy needs are met without overloading the system.

HOW DOES SOLAR INSTALLED ON A TRUCK PERFORM DURING WINTER?

During winter, solar energy production can reduce due to shorter daylight hours and potential snowfall covering panels. However, even in such circumstances, solar panels can generate power, albeit at a decreased capacity. To optimize performance, maintaining the panels clear of debris and snow will enhance energy yields. Additionally, owners may consider having a higher output capacity to balance seasonal inefficiencies.

To sum up, purchasing solar panels for a bed truck demands a nuanced approach focused on understanding electrical specifications, calculating energy consumption, evaluating available solar outputs, and appraising financial commitments. These interconnected factors provide a clear framework from which to engage in informed decisions. By diligently considering each facet, truck owners can ensure successful solar panel integration, leading to enhanced sustainability and energy independence. Investing in solar technology represents not only a commitment to environmental stewardship but also a pursuit of practical energy management that aligns with contemporary living. Consequently, careful evaluation and strategic planning pave the way for achieving a reliable energy source tailored specifically to individual needs, resulting in a seamless electricity experience for diverse truck functionalities.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-v-do-i-need-to-buy-solar-panels-for-a-bed-truck/