The capacity of a coal silo directly depends on its dimensions and design specifications. 1. A standard coal silo can generally store between 100 to 400 tons of coal, providing enough space for varying operational needs. 2. The largest silos, often utilized in industrial settings, can hold upwards of 1,000 tons or more, being designed to cater to high-volume requirements. 3. The ability to store coal efficiently influences operational productivity and logistical management, ensuring a smooth supply chain for energy production. 4. Silo design must consider factors such as material properties, environmental conditions, and operational demands, ensuring safety and efficiency in handling coal inventory over time.

1. UNDERSTANDING COAL SILOS

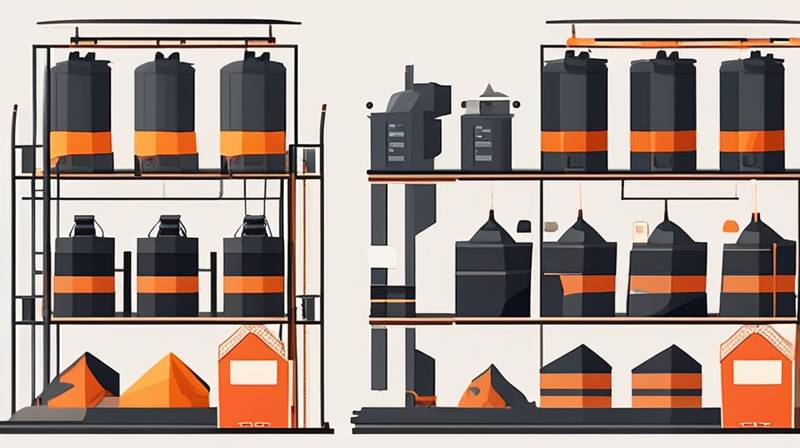

Coal silos are specialized structures designed to store bulk quantities of coal, essential in various industries, primarily energy generation. At the core of their design is the need to accommodate a large volume of coal, maintain quality, and ensure easy access for transportation and usage. The capacity of these silos is influenced by several factors, such as the physical dimensions, construction material, and specific engineering design.

The dimensions typically encompass height, width, and overall shape; common configurations include cylindrical and conical forms. Understanding these factors can lead to better operational efficiency in coal handling, reducing costs and minimizing downtime.

2. FACTORS INFLUENCING STORAGE CAPACITY

The design and functional capability of coal silos hinge upon several critical factors. Material composition and properties of the coal significantly affect the design requirements. Different coal grades have varying densities and flow characteristics, influencing how they compact within the silo. For instance, high-density coal may exert more pressure on walls, necessitating stronger construction materials.

In addition to material considerations, the engineering layout must accommodate the coal’s physical behavior during both loading and unloading. Adequate sloping, aeration systems, and discharge mechanisms must be integrated to facilitate smooth operations.

3. COAL SILO DESIGNS AND DIMENSIONS

Different designs of coal silos correspond to their intended volume capacity and operational environments. Larger silos are often engineered with reinforced concrete or steel structures, capable of sustaining significant weight and pressures from the stored coal. These designs may involve multiple compartments, allowing for segregating different coal grades or managing inventory more effectively.

Dimensions of silos can vary widely, from smaller installations at local facilities, holding 100 tons, to immense structures in power plants that may exceed 1,000 tons. Height and diameter are crucial measurements, as larger diameters often mean greater volume, but height must also be considered to ensure the silo’s capacity aligns with loading and transportation systems.

4. OPERATIONAL CONSIDERATIONS FOR SILOS

Operational efficiency in coal management necessitates effective silo design and planning. The silo should be positioned strategically near transportation links such as rail or road, enabling easy access for fuel supply and distribution. Infrastructure must accommodate the loading and unloading of coal without causing delays or damage.

Furthermore, safety protocols are essential in managing coal dust and preventing explosions, which can occur if fine particles become airborne. Adequate ventilation and dust suppression measures must be in place while ensuring that maintenance practices safeguard against wear and retain operational integrity.

5. ECONOMIC IMPLICATIONS OF COAL STORAGE

The economic impact of coal silo storage is multifaceted. Effective coal storage can lead to reduced freight costs and minimize interruptions in supply chains, enhancing productivity across various sectors. Conversely, poorly designed or maintained silos can lead to significant expenses due to inventory loss, safety incidents, or operational delays.

Investing in quality silo construction and technology upgrades can yield substantial returns, particularly in high-demand regions. Implementing automated systems for monitoring coal levels and qualities can further streamline operations, ensuring that facilities can respond quickly to changing market demands.

6. ENVIRONMENTAL IMPACTS OF COAL STORAGE

The environmental ramifications of coal storage warrant significant consideration. Coal silos can contribute to pollution if not managed carefully, with coal dust becoming an issue during transport and storage. Emissions from stored coal, whether from degradation or spontaneous combustion, must be monitored to mitigate adverse effects on health and the environment.

Innovations in environmentally friendly storage technologies aim to minimize these impacts, employing solutions that reduce dust emissions while enhancing coal quality. Implementation of green technology not only helps in maintaining compliance with environmental regulations but also improves a company’s public image and market competitiveness.

7. CASE STUDIES IN COAL SILO USAGE

Examining real-world examples can illustrate the broad applications of coal silos across industries. One notable instance includes a large power facility that optimized its coal storage through a comprehensive redesign of its silo system, transitioning from traditional flat-bottom silos to more efficient conical designs. This change resulted in an increase in storage capacity and a decrease in operational costs.

Another case highlights a steel manufacturing plant that integrated high-capacity silos, allowing for expanded production capabilities and streamlined coal handling processes. These examples underscore the importance of adaptable and innovative silo designs in meeting evolving industry demands.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE AVERAGE CAPACITY OF A COAL SILO?

The typical capacity of coal silos ranges from 100 tons to over 1,000 tons, depending on their specific application. Smaller facilities may utilize silos designed for several hundred tons, while large industrial systems often incorporate silos capable of holding or exceeding 1,000 tons of coal. This variance allows businesses to select storage solutions that align with their operational needs and logistics.

HOW DOES THE DESIGN OF A COAL SILO AFFECT COAL QUALITY?

The design of a coal silo plays a crucial role in maintaining coal quality. Key factors include the material of construction, the shape of the silo, and ventilation systems. Poor design can lead to moisture retention and the formation of clumps, affecting combustion efficiency and coal integrity. Conversely, effective design that allows for good airflow helps in preserving coal quality, minimizing degradation due to environmental exposure.

WHAT ARE THE SAFETY MEASURES REQUIRED FOR COAL SILOS?

Coal silos require strict safety protocols to manage risks associated with coal dust and potential explosions. Regular maintenance checks, effective dust suppression systems, and employee training are pivotal. Implementing monitoring systems to detect unsafe conditions, such as gas buildup, is crucial. Careful design ensuring adequate load-bearing structures and ventilation plays a significant role in mitigating hazards associated with coal storage.

Coal silo design and operational efficiency are critical components of managing coal inventory and enhancing production capabilities. Understanding the intricacies of coal storage, from dimensions and capabilities to environmental implications and safety precautions, enables companies to optimize their operations effectively. As industries continue to evolve, the need for innovative approaches in coal handling will be paramount, promoting not only productivity but also sustainability in the energy sector. By investing in advanced technologies and adhering to best practices, facilities can better prepare to navigate the challenges of coal storage, ensuring a reliable supply chain that meets both market demand and environmental standards. Proper implementation of these strategies not only enhances the safety and efficiency of operations but also contributes positively to the broader environmental landscape, reflecting a commitment to responsible industrial practices. In an era of rapid change, the coal industry can benefit immensely from thoughtful silo design and management, securing its role in the future of energy production.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-tons-of-coal-can-a-coal-silo-store/