The volume of steam energy storage tanks varies based on several factors, including the intended purpose, the specific application, system design, and energy requirements. 1. The size of the tank is fundamentally determined by operational capacity, 2. A steeper demand curve may necessitate larger tanks for efficiency, 3. The thermal energy storage system’s specifications guide cubic meter requirements, and 4. Industry standards may influence tank dimensions. For a detailed understanding, let us delve deeper into essential aspects surrounding steam energy storage tank dimensions, considerations impacting their size, and relevant factors that play a crucial role in maximizing energy efficiency.

UNDERSTANDING STEAM ENERGY STORAGE

Steam energy storage serves as a pivotal technology in energy management and efficient thermal energy distribution. During peak times, systems harness excess energy to produce steam, subsequently storing it for later use. Consequently, this technique aids in balancing supply and demand, which is vital for maintaining stability in energy grids.

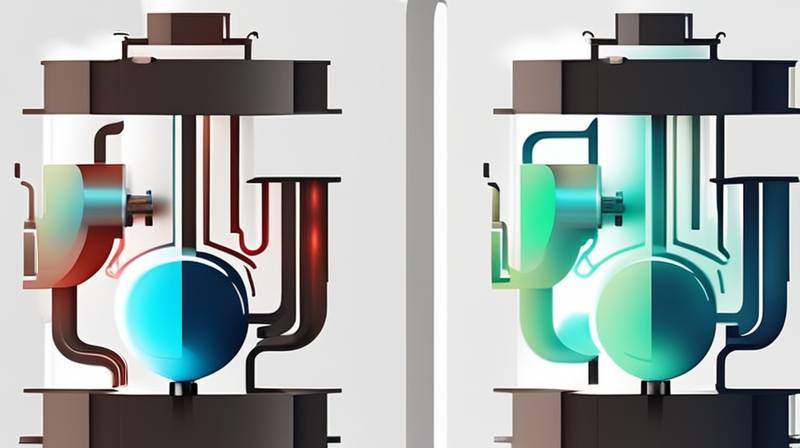

In terms of functionality, steam energy storage operates by capturing and storing thermal energy within a medium, such as water or specialized materials. This energy can subsequently be retrieved for electricity generation, heating applications, or other uses deemed necessary.

The system’s complexity varies based on the required efficiency levels and application specifics. Some industrial sectors, such as manufacturing and power generation, extensively utilize steam storage tanks. These applications necessitate a deep understanding of the intricate characteristics that affect design and capacity.

Furthermore, storage tanks must accommodate variations in operational conditions, energy sources, and demand patterns. It is thus of utmost importance to assess and analyze these factors when determining the ideal cubic meters of a steam energy storage tank.

CAPACITY ESTIMATION CONSIDERATIONS

In considering the optimal cubic meters for steam energy storage tanks, diverse criteria come into play. These criteria include thermal energy requirements, operational cycles, and future demand forecasts. Each element contributes significantly to the overall capacity estimation process.

THERMAL ENERGY REQUIREMENTS

One of the primary determinants in establishing tank volume is the thermal energy demand of the facility or system being considered. By thoroughly assessing heating needs, companies are able to predict how much steam will need to be generated and stored. Explicitly, this foresight enables the specification of tank size, which should be conducive to meeting energy requirements during variable operating conditions.

Additionally, various methodologies may be employed to calculate specific thermal demands. Cumulative energy demands are often recorded over time to establish peak load scenarios which the storage tank must accommodate. For sectors requiring consistent heating or large-scale power generation, precise calculations are pivotal to maintaining efficiency.

OPERATIONAL CYCLES

Operational cycles, which encapsulate the periodicity of energy utilization and storage processes, exert considerable influence on size. Facilities may alternate between periods of high demand and low activity. Understanding these cycles aids in determining how much steam can be effectively stored for immediate retrieval during peak demand periods.

Moreover, companies fluidly adjusting their storage capacity in response to real-time energy usage data can optimize performance. This approach often entails setting tanks to different sizes based on seasonal demands, making it crucial for capacity planning and systematic energy management.

INFLUENCE OF DESIGN PARAMETERS

The design elements integral to steam energy storage tanks further illustrate the nuances surrounding their cubic meter capacity. Materials, insulation types, and engineering specifications all critically affect design characteristics and efficacy.

MATERIALS AND INSULATION

Materials selected for the tank’s construction play an influential role in overall performance. Robust materials are essential to ensure structural integrity under high temperatures and pressures. Appropriate insulation also contributes significantly to thermal retention, minimizing heat loss and enhancing operational efficiency.

In many cases, highly durable, insulated steel is preferred due to its strength and long-lasting properties. But, other alternatives like aluminum or specialized composites are equally viable depending on specific operational needs. Each material impacts allowable pressure ratings, which can influence tank dimensions and the total feasible cubic meters.

ENGINEERING SPECIFICATIONS

Another critical aspect to consider is the engineering specifications that govern tank design. Elements such as safety margins, pressure controls, and regulatory guidelines dictate operational parameters. Compliance with established codes and standards ensures that steam energy storage tanks function optimally, with safety retained as a priority.

Engineers must strategically assess the acoustic, thermal, and mechanical stresses imposed on the vessel. Through rigorous testing and evaluation, they can determine viable tank sizes while considering operational scenarios. This informed approach aids in maximizing effective energy storage and retrieval rates.

INDUSTRY STANDARDS AND REGULATIONS

Incorporating industry standards and regulations into the assessment process assures consistency across design and functionality. Adhering to these guidelines also guarantees that steam energy storage systems operate safely and reliably.

REGULATORY CONTEXT

Regulatory frameworks often necessitate compliance with specific safety and operational benchmarks. These regulations stem from comprehensive energy policies aimed at promoting operational efficacy, sustainability, and public safety. Operators embracing these standards are likely to have clearer frameworks guiding their cubic meter decisions, thus reducing uncertainty.

For example, inspections by regulatory authorities may apply, ensuring that tanks meet environmental standards governing emissions and energy use. Consequently, capacity decisions may be influenced by compliance requirements, steering operators towards optimal tank size options.

INDICATIVE BENCHMARKS

Benchmarking against industry norms can also provide crucial insights for steam energy storage tank specifications. By examining best practices, operators can identify trends in design and construction, ensuring they achieve a competitive edge.

Historical performance data often assists businesses in establishing benchmarks surrounding energy efficiency and operational savings. Over time, these indicators will enable better forecasting of energy needs, influencing capacity planning and adjustments accordingly.

FUTURE DEMAND FORECASTING

Anticipating future energy requirements fundamentally informs decisions regarding the cubic meters of storage adjunct systems. Accurate predictions safeguard against inefficiencies while providing an adaptable framework to align with evolving demands.

UTILIZATION OF ANALYTICS

Analyzing energy consumption patterns is essential for constructing reliable forecasts, as it allows operators to identify trends and anticipate potential courses of change. Leveraging advanced analytics tools can present a comprehensive view of energy consumption across various timeframes. This clarity improves understanding of operational demands and informs capacity planning practices effectively.

Accurate predictive analytics facilitate proactive capacity adjustments. By adapting to anticipated needs beforehand, operators can mitigate energy shortfalls and associated financial ramifications while maximizing resource utilization.

LONG-TERM STRATEGIES

Incorporating a long-term vision into storage capacity assessments enhances resilience and adaptability. Strategically planning cubic meters of storage based on future projections involves understanding not only current demands but also potential growth trajectories and market shifts.

In some instances, companies may proactively design systems to accommodate future expansions, ensuring seamless interchanges in operations without necessitating total overhauls. By effectively aligning current capacities with anticipated changes, businesses can maintain competitive advantages and operational stability.

FAQs

WHAT IS STEAM ENERGY STORAGE?

Steam energy storage involves capturing excess thermal energy to generate steam, which is then stored for later use. This technique optimally balances energy supply and demand, vital for stabilizing energy grids and improving efficiency. The process entails capturing heat energy, often during peak generating conditions, transforming it into steam, and storing it in insulated tanks. The steam can later be released to power turbines or for other industrial processes, retaining its energy efficiency. Thermal energy can be stored for various durations, catering to operational requirements and improving overall energy system responsiveness.

HOW DOES ONE DETERMINE THE SIZE OF A STEAM ENERGY STORAGE TANK?

Determining tank size fundamentally revolves around assessing thermal energy requirements and operational cycles specific to an application. Major factors include evaluating peak and average thermal demands and considering variations in those demands over time. Additionally, comprehending material specifications, insulation properties, and applicable industry regulations impacts the decision-making process. By utilizing predictive analytics to analyze energy usage patterns, organizations can develop effective forecasting models, ensuring the optimal cubic meters of capacity are established.

WHAT ARE THE KEY ADVANTAGES OF STEAM ENERGY STORAGE?

The primary benefits of steam energy storage encompass increased system reliability, enhanced energy efficiency, and improved responsiveness to fluctuating energy demands. This technology mitigates peak energy consumption issues, allowing for deferred energy costs, and maximizes potential savings. Furthermore, steam energy systems contribute positively to grid stability and renewable energy utilization efficiencies, accommodating the integration of intermittent energy sources. Investing in such technology not only fosters economic advantages but also aligns operations with sustainable energy practices aimed at reducing carbon footprints.

In a world where energy management is paramount, the determination of appropriate cubic meters for steam energy storage tanks embodies a multifaceted challenge. This complexity requires a thorough evaluation of operational characteristics, specific requirements, and regulatory frameworks, ensuring successful implementation. Ultimately, accurate measurements guide the effectiveness of energy systems while promoting reliability and enhancing efficiency. The intricacy of energy storage is intertwined with the evolving landscape of energy consumption, rendering proficiency in understanding steam energy storage tanks essential for future-proofing energy infrastructure. Without doubt, the growing emphasis on sustainable energy practices will dictate ongoing developments in this sector, urging continuous exploration and adaptation toward innovative solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-cubic-meters-of-steam-energy-storage-tank/