How low is the solar thermal insulation pipe

The question regarding the solar thermal insulation pipe pertains to its ability to withstand low temperatures, which directly influences efficiency and performance. 1. The typical operating temperature range of these pipes is between -40°C and 100°C, 2. Insulation thickness plays a pivotal role in heat retention, 3. Material selection affects overall durability at lower temperatures, 4. Installation techniques impact thermal efficiency significantly. It is essential to elaborate on these points as they determine the effectiveness and feasibility of utilizing solar thermal technology in various climatic conditions.

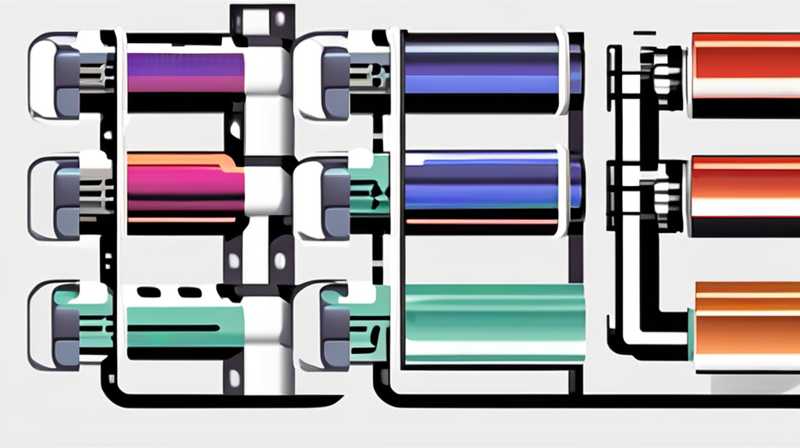

- SOLAR THERMAL INSULATION PIPE OVERVIEW

Solar thermal insulation pipes serve an essential function in harvesting and distributing solar energy effectively. These pipes are specifically designed to minimize thermal losses, enhancing overall system performance. The considerations surrounding operational temperatures are crucial; they dictate not only the materials utilized but also the specific design parameters for which these pipes are engineered. In colder climates, the ability of a solar thermal insulation pipe to maintain operational efficacy, even when ambient temperatures drop, becomes paramount.

Thermal insulation properties are determined by various factors, which include insulation thickness and type of material. The insulation’s ability to retain heat significantly influences the overall efficiency of the heating system. A well-insulated pipe can reduce energy losses, thereby enabling the solar system to operate effectively even under low-temperature scenarios. Understanding the mechanisms behind these properties allows for a clearer insight into the importance of proper insulation in solar thermal systems.

- MATERIAL SELECTION FOR LOW TEMPERATURES

The choice of materials utilized in constructing solar thermal insulation pipes is vital for maintaining performance levels in cooler climates. Common materials include polyethylene, polyurethane, and fiberglass. Each of these materials possesses unique properties that cater to specific thermal insulation needs. For instance, polyethylene is known for its robust resistance to environmental factors, while polyurethane offers superior insulation capabilities, especially in extreme conditions.

Temperature resilience is a critical factor when selecting materials for solar thermal insulation pipes. Each material has a predefined range within which it retains its integrity and insulation efficiency. Using materials with high low-temperature resistance can ensure that heating is not compromised when subjected to environmental stressors. Additionally, ensuring that materials are corrosion-resistant will enhance the longevity of the piping system and provide consistent thermal performance over time.

- INSULATION THICKNESS AND ITS IMPACT

The thickness of the insulation applied to solar thermal pipes plays a crucial role in achieving optimal thermal efficiency. Thicker insulation provides better heat retention, especially in colder weather conditions. This layer of insulation acts as a barrier to unwanted heat loss, which is paramount in maintaining the system’s efficiency. Calculation of the appropriate insulation thickness after assessing local climatic conditions becomes necessary, as insufficient insulation can impair performance significantly.

Moreover, the method of insulation application can vary based on the intended use and environmental conditions. Different installations might require variable thicknesses and insulation types to accommodate specific requirements. Technicians typically engage in rigorous calculations and assessments to determine the optimal thickness needed for the intended operating environment, employing industry standards and practices to achieve desired results.

- INSTALLATION TECHNIQUES THAT ENHANCE PERFORMANCE

The efficiency of solar thermal insulation pipes is heavily dependent on installation methods and techniques. Correct installation can mitigate potential thermal losses, ensuring that the energy harvested remains within the system for as long as possible. Techniques such as proper sealing and joint construction are necessary to avoid leaks that can diminish performance. Specialized training in installation practices often helps technicians better tackle environmental challenges.

Attention to detail during installation can lead to significant performance improvements. Ensuring that pipes are placed at optimal angles for solar gain maximum can result in increased energy harvesting. Additionally, conducting proper evaluations of the installation site protects against future issues arising from environmental factors, including cold weather. Regular maintenance of the system also contributes with respect to ensuring long-term functionality.

- THERMAL PERFORMANCE UNDER VARIOUS CONDITIONS

Evaluating the thermal performance of solar thermal insulation pipes under various conditions is essential for optimizing their use. Temperature fluctuations can affect fluid dynamics within the pipes and ultimately affect efficiency. Such dynamics can lead to reduced energy output if not managed properly. Comprehensive assessments that incorporate local temperature ranges, expected weather patterns, and operational demands are necessary to ensure optimal performance.

Furthermore, enhancing the thermal performance of solar systems involves strategic monitoring and adjustments based on observed conditions. Detailed analysis of performance data allows stakeholders to identify energy losses and make informed decisions on necessary upgrades or modifications. These evaluations can also help in anticipating and mitigating potential issues before they significantly impact overall system performance.

- REGULATORY COMPLIANCE FOR INSULATION PIPING

Adhering to local and national regulations concerning solar thermal installations cannot be overlooked. Standards set by governing bodies outline acceptable material specifications and installation practices. Compliance ensures that the systems installed are safe, reliable, and effective. Regular audits, certifications, and adherence to best practices in insulation piping are critical components of maintaining compliance.

Professional consultations with experts in solar technology and local regulations are advisable. Such consultations will ensure that systems meet all necessary codes, fundamentally supporting efficiency and longevity. Ensuring compliance also facilitates the access to potential governmental incentives or rebate programs designed to encourage the adoption of renewable technologies, which can significantly enhance the feasibility of solar thermal projects.

FAQs

WHAT TEMPERATURES CAN SOLAR THERMAL INSULATION PIPES OPERATE IN?

Most solar thermal insulation pipes are designed to operate in a temperature range from -40°C to 100°C. This wide range enables effective heat retention and distribution under varying environmental conditions. The materials used, along with the insulation thickness, are crucial factors that contribute to the capabilities of these pipes. For instance, insulation made from polyurethane offers superior performance in extreme cold, while polyethylene may perform adequately in less severe conditions, ensuring durability and effectiveness throughout its life span. By standing up to lower temperatures, the pipes ensure that the energy collected during peak hours is retained and effectively utilized when needed, thus enhancing the efficiency of the solar thermal system.

HOW DOES INSULATION THICKNESS AFFECT THERMAL EFFICIENCY?

The thickness of insulation directly correlates to thermal efficiency, particularly in minimizing energy losses. Thicker insulation serves as a more robust barrier against heat escape, ensuring that the energy harvested from solar sources remains available for use. For example, in climates where extreme cold is prevalent, having an adequate insulation layer can prevent significant drops in system performance. Conversely, inadequate or thinner insulation can lead to considerable energy losses, diminishing the overall outcome of solar thermal systems, as heat will escape more readily in low temperatures. Therefore, careful calculations regarding insulation thickness and material type are essential to achieving desired performance levels.

WHAT REGULATIONS SHOULD BE CONSIDERED WHEN INSTALLING SOLAR THERMAL SYSTEMS?

Several regulations exist at both local and national levels that govern the installation of solar thermal systems. These can include material specifications, installation practices, building codes, and safety considerations. Adhering to these regulations not only ensures that the installation complies with legal standards but also promotes efficiency and safety in operation. Consulting with local authorities or industry experts prior to commencing installation can provide insights into applicable guidelines. Moreover, compliance with these regulations can open avenues for incentives and rebates from governmental bodies, thereby enhancing the fiscal feasibility of solar thermal projects and encouraging wider adoption of renewable energy technologies.

The intricate details surrounding the thermal insulation of solar pipes are pivotal in understanding their efficiency and longevity. Factors such as material selection, insulation thickness, installation techniques, and adherence to regulations must be critically examined. Each element contributes to how well solar thermal systems perform, particularly in low-temperature scenarios. Additionally, continuous monitoring and strategic assessments provide valuable insights that can lead to enhancements in performance and operational stability. As such, ensuring that each element is aligned with industry standards supports the durability and effectiveness of solar thermal systems, laying the groundwork for sustainable energy practices in diverse environments.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-low-is-the-solar-thermal-insulation-pipe/