1. A solar aluminum profile typically ranges in length from 2 meters to 6 meters, depending on the application and manufacturer. The dimensions are standardized based on the specific needs of solar energy systems, such as solar panels, racking, and mounting solutions. To illustrate, profiles designed for residential solar installations might be closer to 2 meters, while those used in commercial settings often extend to 6 meters for efficiency and fewer connections. Each profile can be customized for unique project specifications, including cutting to desired lengths, ensuring compatibility with the overall solar structure.

1. INTRODUCTION TO SOLAR ALUMINUM PROFILES

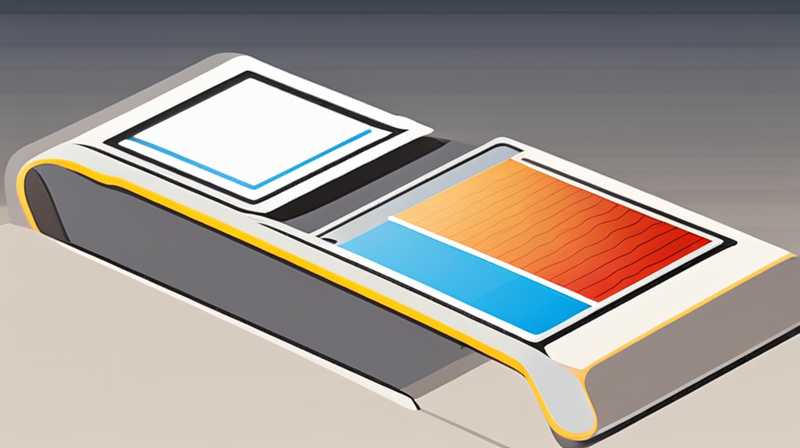

Solar aluminum profiles serve as vital components in solar energy systems. These profiles are extruded aluminum sections specifically designed to support solar panels and integrate seamlessly into various frameworks. Their lightweight nature and strength make them an ideal choice for mounting solar panels on rooftops, ground installations, or solar farms. Understanding the dimensions and characteristics of these profiles is crucial for engineers, architects, and homeowners looking to optimize solar installations.

The specifications of solar aluminum profiles are essential for ensuring structural integrity and enhancing the efficiency of solar energy systems. These profiles are engineered for specific applications, meaning their lengths may vary based on project scope, local regulations, and environmental conditions. Exploring the factors that influence the length and dimensions of these profiles can provide insights into their performance and practical use in solar applications.

2. FACTORS INFLUENCING THE LENGTH OF SOLAR ALUMINUM PROFILES

Several variables impact the length of solar aluminum profiles, including application types, installation environments, and design standards. Depending on the solar energy system’s requirements, profile lengths can be tailored to meet project specs. The choice between using shorter or longer profiles may depend on specific project demands, such as load-bearing capacity, installation convenience, and aesthetic considerations.

Application types play a significant role in determining the dimensions of aluminum profiles. For residential setups, shorter lengths tend to suffice due to the limited space on rooftops. In contrast, larger-scale operations, like utility-scale solar farms, benefit from longer profiles since they cover more extensive areas, thereby reducing the number of connections. Designing frameworks that use longer sections can lead to cost efficiencies by minimizing material and labor expenditures related to installation and assembly.

3. TYPICAL LENGTHS AND SIZES OF SOLAR ALUMINUM PROFILES

In the realm of solar energy, typical lengths for aluminum profiles usually fall between approximately 2 meters and 6 meters. Residential installations commonly utilize shorter profiles, often measuring around 2 to 3 meters, which fit well on most rooftops while allowing for flexible installation configurations. These shorter segments enable installers to navigate various obstacles, like chimneys or skylights, with greater ease.

Meanwhile, commercial or utility-scale projects frequently leverage longer profiles to maximize efficiency. Lengths extending from 4 to 6 meters are typically employed in these scenarios. Such dimensions are conducive to broader panel arrays and the establishment of durable mounting systems. By using longer lengths, engineers can design strong frameworks that withstand extreme weather and support heavier panel weights, ensuring all aspects of the installation operate as intended across different environmental conditions.

4. CUSTOMIZATION OF ALUMINUM PROFILES FOR SOLAR APPLICATIONS

Customization is another crucial component in the world of solar aluminum profiles. Manufacturers offer various sizes and lengths to meet client specifications, allowing for tailored solutions based on individual needs. This adaptability ensures that solar installations align seamlessly with site-specific conditions, maximizing efficiency while enhancing visual appeal.

For instance, specific alterations may include angular cuts, holes for mounting hardware, or channels for electrical wiring. These customizations not only provide structural support but also facilitate integration with other components of the solar installation. By allowing personalization of the profiles, manufacturers accommodate diverse applications, preferences, and environments, thus enabling optimal performance of solar energy systems.

5. ENVIRONMENTAL IMPACT ON LENGTH REQUIREMENTS

The surrounding environment significantly impacts the selection of solar aluminum profile lengths. Weather conditions, geography, and climate patterns are key determinants in how profiles are designed and deployed in various locales. Profiles situated in harsher climates may necessitate different lengths or reinforcements to withstand strong winds, heavy snow loads, or extreme temperatures, ensuring their longevity and reliability.

Moreover, manufacturers often consider regional factors when standardizing the lengths of aluminum profiles. Areas prone to severe weather events may require longer and thicker profiles to provide the necessary structural integrity. Conversely, regions with milder climates may opt for shorter lengths, focusing more on aesthetic appeal without compromising functionality.

6. INSTALLATION CONSIDERATIONS FOR LENGTH SELECTION

Choosing the appropriate length of aluminum profiles during solar installation is pivotal. Installation methods, logistical concerns, and local building standards influence how these profiles are employed. Properly assessing the installation environment is essential for engineers and contractors to decide on the most suitable profile lengths.

Logistics play a critical role as well. Longer profiles may present challenges during transport and handling, especially in urban or densely populated areas. Conversely, shorter profiles are more manageable and facilitate easier installation, particularly where access is limited. Adequate training and safety measures must be taken into account to ensure the effective handling of any profile length during the installation process.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON MATERIALS USED IN SOLAR ALUMINUM PROFILES?

Aluminum is the predominant material utilized in solar profiles due to its myriad advantages. It possesses an excellent strength-to-weight ratio, allowing for structures that are both lightweight and sturdy. The corrosion resistance inherent in aluminum ensures its longevity, even in harsh environmental conditions. Often, these profiles are further treated by anodizing, a process that thickens the natural oxide layer, enhancing durability and aesthetics. Additionally, manufacturers may incorporate alloys to achieve desired physical properties, such as enhanced tensile strength or malleability. In some cases, profiles are designed to accommodate integrated features like cable management or thermal expansion, showcasing the versatility of this material in solar applications.

HOW DOES THE LENGTH OF A SOLAR ALUMINUM PROFILE AFFECT PERFORMANCE?

The length of solar aluminum profiles directly influences their performance and overall efficiency in photovoltaic systems. Longer profiles can minimize the number of joints required, reducing potential weakness points where structural failure could occur. They also provide greater stability under wind and snow loads. However, while longer profiles present several benefits, shorter ones may be necessary for certain installations due to spatial constraints or design choices. Selecting the appropriate length ensures that systems operate effectively while maintaining safety standards and meeting structural requirements. Moreover, distinguishing lengths based on environmental conditions is vital, as profiles designed to withstand specific weather patterns are more likely to perform efficiently over time.

CAN SOLAR ALUMINUM PROFILES BE RECYCLED?

The recyclable nature of aluminum makes it an environmentally friendly choice for solar profiles. Most profiles are composed of high-purity aluminum, which can be recycled indefinitely without degradation of its properties. Recycling aluminum requires significantly less energy than producing new aluminum, leading to reduced greenhouse gas emissions. Many manufacturers and industry stakeholders have initiated programs to collect and recycle old or damaged solar profiles, promoting sustainable practices within the sector. This commitment to recycling aligns with the overarching goals of solar energy systems, which aim to minimize environmental impact while maximizing energy efficiency. As such, selecting aluminum profiles not only benefits installation performance but also supports broader sustainability efforts.

IN SUMMARY, understanding the exact lengths of solar aluminum profiles entails examining various aspects that influence their dimensions. Many factors, including application types, installation environments, design standards, and environmental influences contribute to the specifications and characteristics of these profiles. It is essential to choose the appropriate length to ensure optimal performance, structural integrity, and alignment with regulations. Ultimately, investing in high-quality aluminum profiles tailored to specific project needs can significantly enhance the functionality and durability of solar energy installations, supporting the transition to renewable energy. The emphasis on customization, sustainability, and the variety of options available signifies a continually evolving industry poised for further advancements in optimizing solar energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-long-is-a-solar-aluminum-profile/