1. The duration required for solar thermal tape to melt is primarily contingent on several critical factors, including the type of tape employed, the temperature it is exposed to, and the environment in which it functions. 2. Typically, solar thermal tapes reach their melting point within 30 seconds to several minutes when subjected to optimal conditions. 3. Importantly, the melting characteristics can be influenced by the specific thermal properties of the materials involved, necessitating a more in-depth understanding of their behavior under various thermal conditions. 4. Extreme environmental factors, such as direct sunlight or proximity to heat sources, can significantly expedite the melting process, altering the overall timeline.

UNDERSTANDING SOLAR THERMAL TAPE

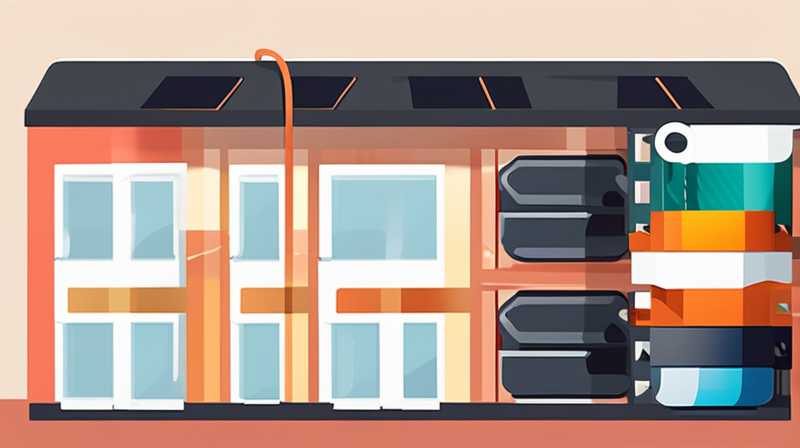

Solar thermal tape is an innovative product designed to aid in the efficient transfer of heat from one surface to another, often utilized in various energy systems, particularly solar thermal installations. This specific type of tape is engineered to withstand different environmental conditions while effectively transferring thermal energy. Understanding the mechanics behind solar thermal tape provides insight into its applications and characteristics.

The primary function of solar thermal tape involves facilitating the transfer of heat between components, often connecting solar collectors to heat storage systems. It is engineered from specific materials that allow it to operate effectively under significant temperature fluctuations while maintaining its structural integrity. The design of solar thermal tape is paramount; its ability to endure prolonged exposure to heat directly influences its efficiency and operational lifespan.

The melting point of any tape, including solar thermal variants, is a vital characteristic that determines its suitability for certain applications. Factors such as the composition materials—often including polymers or specialized adhesive compounds—play a crucial role in setting these thermal thresholds.

1. FACTORS INFLUENCING MELTING TIME

Several essential aspects can affect how quickly solar thermal tape melts. Temperature is arguably the most significant factor in this equation; the higher the external heat applied to the tape, the more quickly it will reach its melting point. Typically, solar thermal tapes are resistant to temperatures ranging from 100°C to 200°C, but prolonged exposure to temperatures exceeding their thresholds can lead to melting.

Another vital consideration involves the quality and composition of the tape. Higher-grade materials designed for thermal resistance may possess enhanced melting points, thereby extending the duration before they succumb to thermal degradation or melting. Conversely, lower-grade materials may lose structural integrity more rapidly. Understanding the material specifications can therefore provide insight into performance expectations.

Environmental conditions also have a profound impact on melting time. For instance, humidity and ambient temperature dictate how effectively heat is transferred to the tape. Higher humidity levels can slow down heat absorption, whereas arid conditions could lead to more rapid heating. Seasonal variations can affect this dynamic, prompting meticulous assessments based on specific locations and climates.

2. CASE STUDIES AND EXAMPLES

Historical data and case studies regarding different installations of solar thermal tape provide excellent insights into its performance characteristics in varied environments. In one prominent study, solar thermal systems equipped with high-grade thermal tape demonstrated efficient operation with minimal deterioration over time. These installations showcased performance in climate zones ranging from arid deserts to temperate regions.

In harsher climates, adaptations have been made, utilizing specialized solar thermal tape with higher heat resistance. For example, installations in regions renowned for extreme sun exposure reported that beginning temperatures significantly influenced the melting timeline. In these cases, mitigatory measures such as incorporating shading elements or reflective surfaces were introduced to sustain optimal temperatures for tape functionality.

Furthermore, considerations of melting time can also intersect with maintenance schedules and safety protocols. In one installation utilizing standard solar thermal tape, rapid exposure to peak temperatures led to accelerated wear and necessitated more frequent inspections to ensure reliability. These insights allow for better-informed decisions regarding material selection and installations’ operational practices.

3. APPLICATIONS OF SOLAR THERMAL TAPE

The applications of solar thermal tape extend beyond merely connecting components in solar thermal systems. In agricultural settings, for instance, this tape aids in achieving optimal heating for greenhouse environments by allowing efficient heat transfer to soil or plant-root zones. Efficiently harnessed solar energy maximizes crop yields and promotes sustainable practices.

Additionally, solar thermal tape finds usage in residential heating systems, wherein it connects solar heat collectors to water tanks, thereby streamlining the conversion of solar energy into usable heating solutions. In these contexts, the efficiency of heated water supply directly hinges on how quickly the tape can operate without degradation.

In industrial applications, solar thermal tapes have started to gain traction in process heating setups, particularly where conventional methods may yield insufficient energy efficiency. Complex industrial systems increasingly favor energy management solutions that leverage sunlight, making this product’s performance imperative to successful outcomes. By understanding the dynamics of effective heat transfer and carefully analyzing melting time under various conditions, industries can modify their approaches to integrate sustainable options meaningfully.

4. OPTIMIZING SOLAR THERMAL TAPE USAGE

Optimizing the usage of solar thermal tape involves an in-depth understanding of the integral factors that contribute to its melting performance and longevity. Implementation of proper installation techniques is critical in maximizing the lifespan and effectiveness of the tape. Ensuring that surfaces are adequately prepared and free of contaminants lays the groundwork for maximum adhesion and heat transfer.

In addition to installation practices, understanding the operational parameters in which the tape will function plays an equally crucial role. Regular inspections of the adhesive’s integrity and monitoring environmental conditions can help preempt potential issues related to melting or degradation. Implementing a thorough maintenance routine serves not only to extend the life of the tape but also to promote overall efficiency in energy systems.

Moreover, training personnel in understanding the properties of solar thermal tape underscores the need for proactive management strategies. Ensuring that installers comprehend the nuances of temperature effects, seasonal variations, and material specifications are pivotal in sustaining optimal functionality.

COMMON CONCERNS REGARDING SOLAR THERMAL TAPE

In the realm of solar thermal tape, certain concerns frequently arise among users. From the integrity of the installation to efficacy in different climates, it’s beneficial for stakeholders to express these perceived uncertainties.

- DURABILITY AND LIFESPAN

A common question often posed is regarding the durability and lifespan of solar thermal tape. Users are seeking clarity on how well the tape withstands environmental stressors over extended periods. Proper assessment of materials and rigorous testing protocols can yield substantial insights into expected longevity. Manufacturers typically indicate lifetimes based on standard conditions, but real-world usage may vary. - EFFECTIVENESS UNDER VARIED CONDITIONS

Questions regarding the effectiveness of solar thermal tapes under differing climatic conditions may arise as well. Solar thermal tape excels in environments with direct sun exposure, but areas with lower solar insulation might question the viability. It is essential to discuss adaptations and innovations that can cater to these unique settings to optimize performance sustainably. -

RECOMMENDATIVE INSTALLATION PRACTICES

Another point of inquiry stems from appropriate installation practices. Users often seek best practices to ensure maximum efficiency, emphasizing the significance of proper preparation in achieving optimal thermal connectivity. Guidelines surrounding detailed installation processes and maintenance schedules can empower users to harness the complete capabilities of solar thermal tape.

In summation, solar thermal tape represents a pivotal component in several applications linked to energy management and sustainability. The melting time of this tape is subject to various factors, including environmental conditions, material quality, and temperature exposure. By understanding these factors, users can maximize the efficiency and longevity of their thermal systems. Armed with insights derived from real-world case studies and best practices, stakeholders can leverage the full potential of solar energy solutions, ultimately steering toward more sustainable futures while ensuring optimal operational performance. This synergy between technology and technique constitutes a cornerstone for the advancement of solar thermal applications. As solar technologies keep evolving, it is essential to remain vigilant, adapt, and educate to fully realize the benefits offered by innovative products like solar thermal tape. Through continuous learning and adaptation, the overall effectiveness of solar thermal systems can improve, promoting a more sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-long-does-it-take-for-the-solar-thermal-tape-to-melt/