Based on the inquiry regarding the duration of usability for a solar oxygen pump, the following points provide clarity: 1. Lifespan typically ranges from 5 to 15 years, according to various manufacturers and environmental factors. 2. Maintenance practices play a critical role in extending life cycle, with regular inspections and parts replacements. 3. Environmental conditions significantly affect performance and longevity, including exposure to harsh weather and placement. 4. Technological advancements continually improve efficiency and durability, indicating potential for longer usage in future models. Notably, regular maintenance deserves further elaboration; it encompasses cleaning the pump, checking seals, and ensuring optimal solar panel positioning to maximize performance and extend the operational lifespan.

1. LIFESPAN OF SOLAR OXYGEN PUMPS

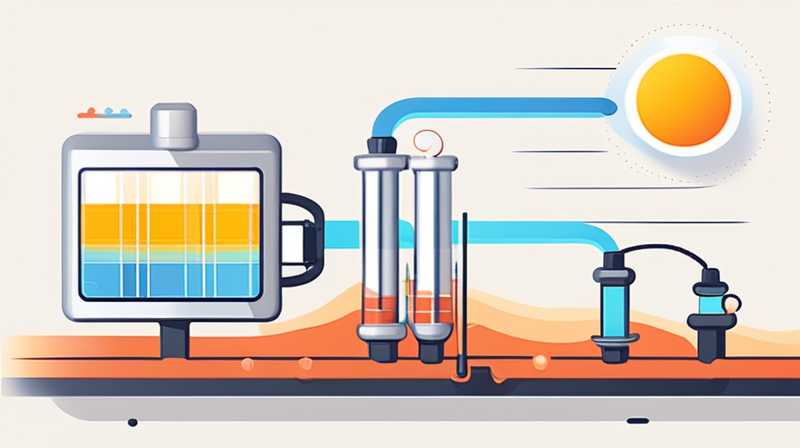

The operational life of a solar oxygen pump is a crucial aspect for users who rely on these systems for aquaculture, wastewater treatment, or remote environmental monitoring. Typically, these devices can function effectively between 5 to 15 years, which is influenced heavily by material quality, technological design, and usage context. The variance in lifespan is characterized by specific elements such as the construction of the pump, the components used, and the manufacturer’s technology. Generally, pumps made from high-grade materials exhibit superior resilience against the elements, thereby extending their usability.

In addition to materials, the design of the pump must be factored into the longevity equation. Innovative technologies have led to designs that minimize wear and tear whilst maximizing efficiency. For instance, a well-engineered diaphragm pump can last longer compared to a standard centrifugal pump in similar environments, owing to its ability to handle various pressures and loads without significant degradation. Consultations with manufacturers can provide specific data that will help prospective buyers make informed decisions about the expected lifespan of potential options.

2. MAINTENANCE REQUIREMENTS

Regular upkeep constitutes another essential factor that can dramatically enhance the operational life of solar oxygen pumps. A well-maintained pump can sustain its functional capacity, ultimately leading to an increased lifespan. Maintenance activities may include cleaning the unit, replacing worn-out seals, checking electrical connections, and ensuring the solar panels are unobstructed. Each of these actions plays a pivotal role in preserving the pump’s performance over time.

For example, cleaning the pump from algae and sediment buildup ensures that the airflow remains optimal and that no blockages hinder the system’s performance. Additionally, maintaining the solar panels free of dirt and debris is crucial as any shading or obstruction can significantly reduce energy input, compromising pump efficacy. Users who neglect these maintenance tasks may find their pumps prematurely failing, leading to increased costs over time when replacing or repairing is necessary.

3. IMPACT OF ENVIRONMENTAL CONDITIONS

Environmentally driven factors significantly shape the longevity and effectiveness of solar oxygen pumps. The geographical location where the pump is deployed can alter its performance based on prevailing weather conditions. For instance, pumps located in extremely hot or cold areas may experience accelerated wear. Factors such as humidity levels, temperature fluctuations, and exposure to elements like saltwater or chemicals can considerably impact the durability of components.

Moreover, consistent exposure to harsh weather conditions can degrade the materials used in the pumps. It is recommended that users select pumps that are particularly designed to withstand specific weather challenges present in their locality. Choosing models with sturdy weatherproofing and corrosion-resistant components can significantly mitigate potential damages caused by such conditions and extend overall usability.

4. TECHNOLOGICAL ADVANCEMENTS AND FUTURE OUTLOOK

The solar oxygen pump industry has witnessed significant technological advancements that positively influence usability over the years. Emerging innovative technologies focus on enhancing not just the efficiency of pumps but also their resilience and lifespan. For instance, solar panel technology has progressed, offering more power from smaller installations, consequently improving the pump’s operational efficiency.

Rather than relying solely on traditional solar designs, manufacturers are experimenting with integrated storage systems allowing pumps to function even during periods of low sunlight. This technological shift implies that future models may not only last longer due to improved materials and build quality but also provide consistent performance under varying conditions. Continuous advancements in smart pump systems could lead to automated maintenance alerts, prompting users to conduct necessary inspections before minor issues escalate.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I MAINTAIN MY SOLAR OXYGEN PUMP?

Routine maintenance is essential to ensuring the optimal performance and longevity of your solar oxygen pump. Generally, checking the unit every three to six months is recommended to keep it in prime working condition. This involves cleaning the pump and solar panels while examining seals for wear or potential issues. If operational environments face heavy debris or algae growth, more frequent checks may be necessary. Regular inspection of electrical connections can help prevent unforeseen failures, allowing for seamless operation.

Consider keeping a maintenance log to track inspections and repairs. This log can help users stay on top of required upkeep, ensuring that any issues are promptly addressed. Additionally, some modern pumps come with sensors and alerts that notify users to perform maintenance tasks. Failure to follow through on regular maintenance can lead to unforeseen breakdowns, ultimately increasing costs due to repairs and replacement. Investing time into proper maintenance not only preserves usability but contributes to a more sustainable operation overall.

WHAT FACTORS CAN AFFECT PUMP LIFESPAN?

A multitude of factors can influence the lifespan of a solar oxygen pump. Primarily, the quality of materials used is a significant contributor. Pumps made from high-grade materials often outperform their lower-quality counterparts, which tends to show wear far sooner. Technological design also plays a significant role, with well-engineered systems imposing less strain on components during operation.

Environmental conditions cannot be overlooked. Factors such as extreme temperatures, humidity, exposure to harsh chemicals, and physical obstructions can negatively impact performance and lifespan. Regions prone to extreme weather may require pumps built with superior weatherproofing features. Proper maintenance practices directly correlate with pump longevity as well; devices that receive regular upkeep endure less wear over time. Understanding these factors can help users make informed decisions when selecting and maintaining solar oxygen pumps.

WHAT SHOULD I DO IF MY SOLAR OXYGEN PUMP STOPS WORKING?

If you find your solar oxygen pump ceasing operations, several steps should be undertaken to diagnose the issue effectively. Begin by checking the solar panels for obstructions such as dirt, debris, or shading. If the panels are blocked from accessing sunlight, removing these obstructions can often restore functionality. Next, examine both the electrical connections and wiring for signs of damage. Loose or corroded wires may require repair or replacement.

Should these initial checks not yield results, further inspection of the pump itself is necessary. Look for blockages within the pump or signs of component wear. A clogged pump could disrupt functionality, while worn components like seals or diaphragms may need replacement to restore performance. If self-diagnosis proves challenging, consider reaching out to a professional repair service familiar with solar oxygen pumps to conduct a thorough evaluation, ensuring any underlying issues are properly addressed.

A comprehensive exploration into the solar oxygen pump’s usability reveals numerous possibilities for extension through various factors including maintenance, environmental conditions, and technological advancements. Emphasizing proper upkeep plays a vital role in achieving optimal performance, as neglect may lead to increased costs or premature failures. Users must remain informed about their pump’s requirements and remain vigilant to signs of wear or malfunction. Ensuring appropriate protections from severe environmental particles and conditions can minimize potential damages, cultivating a longer lifeline for these devices. As technology continues to evolve, the promise of even longer usability periods persists. Such innovations encompass stronger materials and smarter features, ultimately enhancing efficiency and longevity. Overall, the knowledge surrounding solar oxygen pumps expands continually, underscoring the importance of informed choice, precise maintenance, and adaptation to new technologies. Through thoughtful care and selection, users can ensure that their solar oxygen pumps perform optimally for a significant duration, thereby reaping the full benefits of these eco-friendly solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-long-can-the-solar-oxygen-pump-be-used/