Industrial energy storage systems play a pivotal role in reducing greenhouse gas emissions by 1. enhancing energy efficiency, 2. facilitating a transition to renewable energy sources, 3. enabling peak load shaving, and 4. reducing reliance on fossil fuels. These systems store energy generated during periods of low demand or high renewable generation and release it when demand spikes or renewable generation drops. Among these points, the significant impact of energy efficiency stands out as it not only lowers operational costs but also diminishes the overall carbon footprint of industrial operations. Enhanced energy efficiency translates directly into minimized energy consumption, leading to fewer greenhouse gas emissions.

1. ENHANCEMENT OF ENERGY EFFICIENCY

In the realm of industrial energy consumption, efficiency is crucial. Industrial energy storage systems empower businesses to optimize their energy usage by smoothening spikes and troughs in demand. With the integration of advanced storage solutions, factories can harness energy when it is abundant and inexpensive, typically during off-peak hours, and discharge it during periods of high demand, thus avoiding peaks when energy prices can escalate significantly.

The transition to energy-efficient practices is not merely a cost-saving measure; it is also an environmental imperative. By adopting such systems, industries can significantly reduce their greenhouse gas emissions. This integration is particularly advantageous in sectors heavily reliant on energy-intensive processes, such as manufacturing and chemical production. When energy consumption is optimized, the resultant decrease in fossil fuel use corresponds to a lower output of greenhouse gases, directly aiding climate change mitigation efforts.

2. INTEGRATION WITH RENEWABLE ENERGY SOURCES

The synergy between industrial energy storage systems and renewable energy sources is indispensable for achieving decarbonization goals. Energy storage solutions allow for the effective capture of surplus energy generated from renewable sources like wind and solar, storing it for later use. When aligned with industrial operations, these systems can dramatically shift the energy mix from fossil-based sources to cleaner alternatives, thereby reducing carbon emissions substantially.

Renewables face inherent intermittency challenges; thus, the need for reliable storage becomes paramount. Industrial facilities equipped with energy storage systems can operate with a balanced energy supply, compensating for periods when renewables may not produce sufficient energy. This flexibility not only enhances grid reliability but also promotes the growth of the renewable energy sector, fundamentally changing the energy landscape and paving the way for a more sustainable industrial future.

3. PEAK LOAD SHAVING CAPABILITIES

Peak load shaving represents a strategic advantage offered by industrial energy storage systems. By discharging stored energy during peak demand periods, companies can diminish their reliance on grid energy, which often comes from carbon-intensive sources. This practice directly contributes to lowering emissions by limiting the necessity for additional fossil fuel power generation during peak hours.

Furthermore, reducing peak demand not only lessens environmental impact but also leads to substantial financial savings. Industries can avoid higher costs associated with peak-power pricing, thus improving their overall operational efficiency. The pairing of economic benefits with sustainability creates a compelling case for businesses to implement energy storage solutions, aligning profitability with environmental responsibility—a defining trait of modern industrial operations.

4. FOSTERING ENERGY RESILIENCE AND REDUCING FOSSIL FUEL DEPENDENCE

Another significant aspect of energy storage systems is their capacity to enhance energy resilience, particularly in industrial contexts. By providing a buffer against energy supply disruptions, these systems ensure that operations remain uninterrupted even in the face of grid failures. This reliability allows industries to maintain consistent output while pursuing aggressive emissions reduction strategies.

Reducing dependence on fossil fuels is intrinsically tied to these systems as they can seamlessly integrate with low-carbon energy strategies. By promoting the use of stored renewable energy, industries can function with a significantly lower carbon footprint. Emphasizing this shift illustrates a robust commitment to environmental stewardship, positioning businesses as leaders in sustainable practices.

5. TECHNOLOGICAL INNOVATIONS AND POLICY SUPPORT

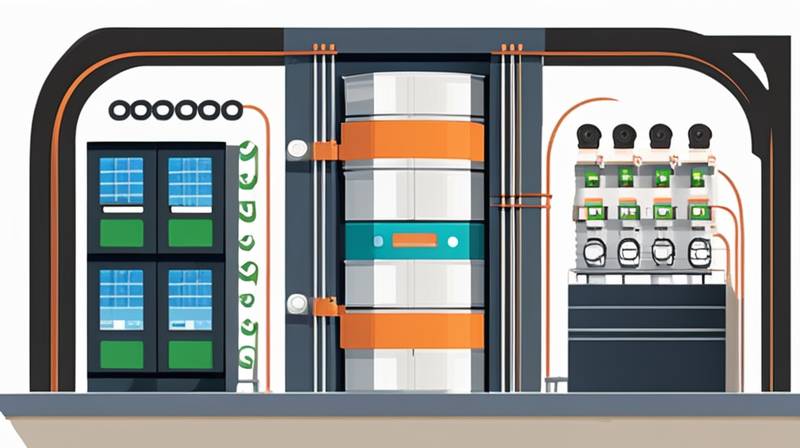

The evolution of industrial energy storage systems is supported by continuous technological advancements that enhance efficiency, reduce costs, and improve storage capacities. Innovative technologies such as lithium-ion batteries, flow batteries, and thermal storage solutions offer new pathways for integration into industrial operations. These advancements not only improve energy management capabilities but also provide industries with diverse options for customized energy storage solutions suited to their specific needs.

Moreover, supportive policies and regulatory frameworks are crucial for promoting the widespread adoption of energy storage technologies. Governments at various levels are increasingly providing incentives for industries to invest in energy efficiency measures, not just for economic benefits but also to aid in achieving national and international emissions targets. Such collaborative approaches enhance the potential of storage systems, ensuring a unified front in addressing climate change.

FAQs

WHAT ARE INDUSTRIAL ENERGY STORAGE SYSTEMS?

Industrial energy storage systems refer to technologies that capture and store energy for later use, primarily within industrial settings. These systems can take various forms, such as batteries, thermal storage, or mechanical systems like flywheels. They play a significant role in managing energy supply and demand, helping industries optimize their energy usage by storing excess energy produced during low-demand periods and discharging it during high-demand phases. The implementation of these systems not only aids in operational efficiency but also significantly contributes to reducing greenhouse gas emissions by lowering reliance on fossil fuels and promoting the use of renewable energy sources.

HOW DO INDUSTRIAL ENERGY STORAGE SYSTEMS REDUCE GREENHOUSE GAS EMISSIONS?

The reduction of greenhouse gas emissions through industrial energy storage systems occurs via several mechanisms. First, by optimizing energy consumption, these systems allow industries to consume less energy overall, directly diminishing fossil fuel requirements. Second, they facilitate the integration of renewable energy by capturing surplus energy generated during peak production times, thus displacing fossil fuel usage. By utilizing stored renewable energy during peak demand, industries can avoid high-emission energy sources, contributing to a significant reduction in overall emissions. Collectively, these mechanisms position energy storage as a vital tool in climate change mitigation efforts.

WHAT ARE THE ECONOMIC BENEFITS OF ADOPTING ENERGY STORAGE SYSTEMS IN INDUSTRY?

Adopting energy storage systems provides numerous economic benefits for industrial operations. Companies can achieve considerable cost savings through peak load shaving, which reduces the need to purchase expensive energy during peak demand hours. Additionally, enhanced energy efficiency leads to lower energy bills over time and a reduced carbon footprint, aligning operational goals with sustainability objectives. Moreover, with regulatory incentives and potential subsidies aimed at promoting energy efficiency and renewable integration, organizations can further offset the costs of implementing these systems. In essence, while the initial investment may be substantial, the long-term financial and environmental dividends are increasingly compelling.

In summary, industrial energy storage systems represent a significant advancement in the pursuit of greenhouse gas reduction. The multifaceted benefits they offer extend beyond mere energy efficiency, enabling industries to operate more sustainably while effectively integrating renewable energy sources. The transition to these systems is not only beneficial for operational costs but also critical for meeting environmental aspirations. Engaging with these technologies fosters a robust framework for resilient industrial practices, enhances the reliability of energy supply, and effectively diminishes the reliance on fossil fuels. This transformative potential underscores the role of innovation in overcoming climate challenges and reshaping the industrial sector’s approach to energy consumption. By leveraging energy storage systems, industries can drive meaningful change, contributing to a healthier planet while maintaining competitive advantages in a rapidly evolving economic landscape. Ultimately, the future of industrial operations hinges upon the successful integration of these systems, redefining our collective approach to energy use and environmental stewardship.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-industrial-energy-storage-systems-can-reduce-greenhouse-gas-emissions/