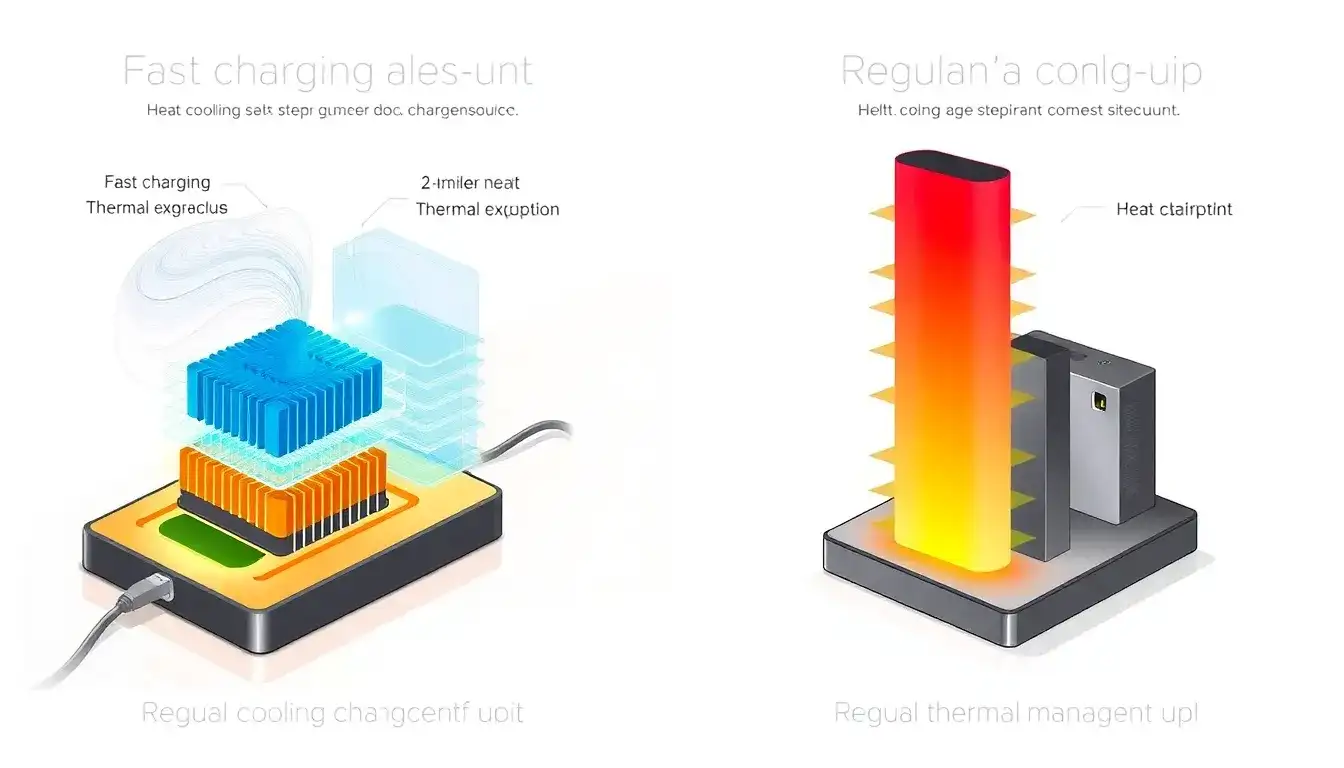

Thermal management differs significantly between fast charging and regular charging, primarily due to the much higher power levels and resulting heat generated during fast charging.

Thermal Management in Regular Charging

- Regular charging (e.g., typical 22 kW AC charging) produces relatively low heat because the charging power is moderate and the charging process is slower.

- The battery temperature tends to remain within a manageable range with basic or passive cooling systems.

- Slow charging typically does not saturate the battery’s thermal mass, so heat dissipation is straightforward and heat loss is less critical.

- Regular charging usually takes place in controlled environments such as home or workplace, where ambient temperatures and cooling options are more favorable, reducing thermal management challenges.

Thermal Management in Fast Charging

- Fast charging requires substantially higher power input (e.g., 150 kW DC chargers) to dramatically reduce charging time (e.g., from 120 minutes to 16 minutes for a 200 km range).

- This high power leads to rapid, significant heat generation within the battery—temperatures can rise to extreme levels (over 270°C reported during a 10-minute fast charge).

- Because of this, fast charging demands advanced, controlled thermal management systems, predominantly involving active liquid cooling solutions like liquid or refrigerant cooling circuits that circulate coolant through the battery pack to efficiently remove heat.

- Thermal management systems during fast charging must handle both battery heating and the heat generated by power electronics within the charging station, requiring robust and reliable heat dissipation mechanisms.

- As the battery’s thermal mass saturates quickly under fast charging, heat loss must be carefully controlled by adjusting charging current or employing enhanced cooling to prevent damaging temperature rises.

- Effective thermal management during fast charging is crucial not just to prevent overheating but also to protect battery health, maintain battery longevity, ensure safety, and sustain consistent charging speeds without interruptions.

- Fast charging thermal management systems are more complex and costly due to the need for high-capacity cooling infrastructure, especially in variable ambient temperature conditions or extreme climates.

Summary Table of Differences

| Aspect | Regular Charging | Fast Charging |

|---|---|---|

| Charging Power | Low to moderate (e.g., 22 kW AC) | High (e.g., 150 kW DC or more) |

| Heat Generation | Moderate | Very high, rapid temperature rise (up to 270°C) |

| Thermal Mass Saturation | Rare | Occurs quickly, requiring heat loss control |

| Cooling Type | Often passive or basic active | Controlled active cooling (liquid/refrigerant) |

| Impact on Battery | Minimal thermal stress | High thermal stress; risk of damage without management |

| Charging Station Heat | Low | Significant heat generated in electronics |

| Infrastructure Complexity | Lower | High, with robust cooling systems needed |

| Battery Safety Concerns | Lower | High; thermal management critical to prevent damage and maintain longevity |

| Ambient Temperature Challenges | Less critical | More challenging, requires adaptive cooling |

In essence, fast charging requires significantly more sophisticated and actively controlled thermal management systems compared to regular charging due to the much higher power levels and resultant thermal stresses on the battery and charging equipment.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-thermal-management-differ-between-fast-charging-and-regular-charging/