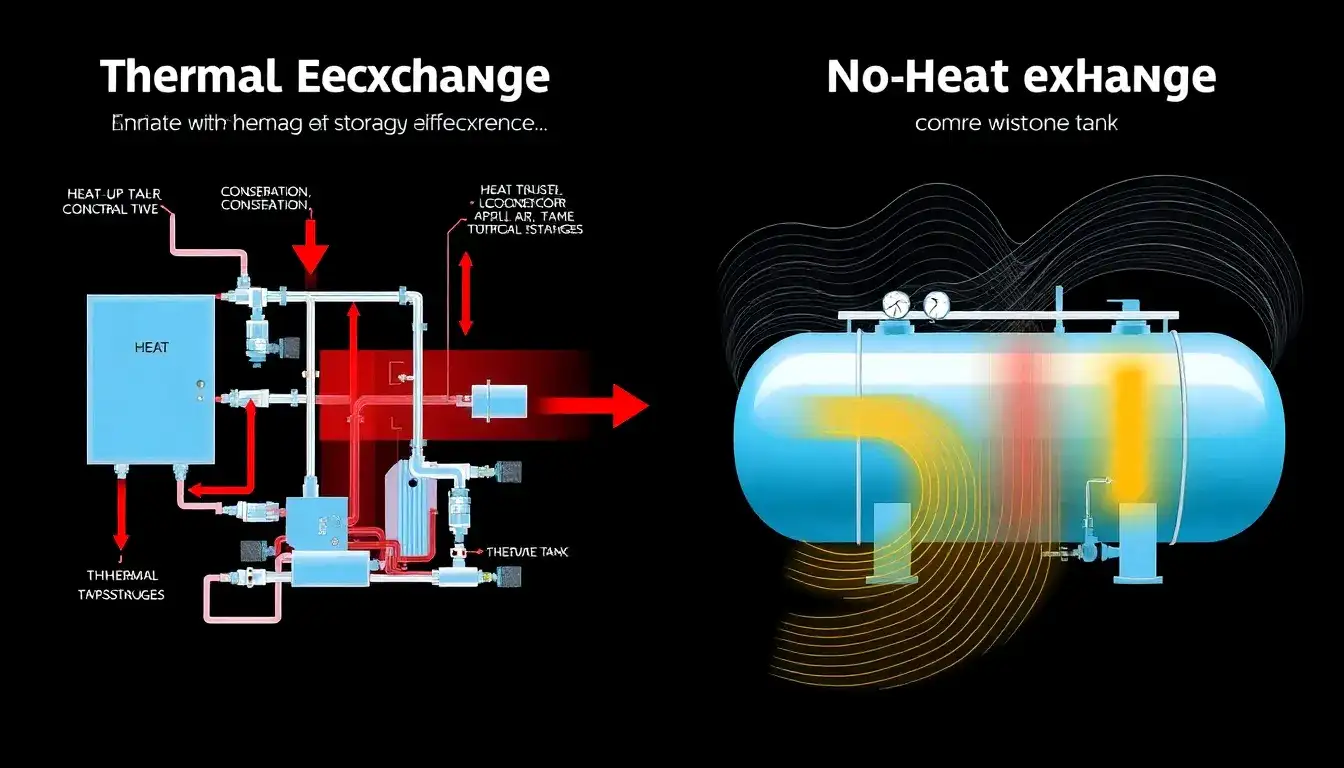

Thermal energy management fundamentally distinguishes diabatic and adiabatic Compressed Air Energy Storage (CAES) systems by how they handle the heat generated during air compression and utilized during expansion.

Thermal Energy Management in Diabatic CAES

- In diabatic CAES, the heat produced during the compression phase is not retained for reuse. Instead, it is typically released into the environment, resulting in thermal energy loss.

- During the air expansion (discharge) phase, additional fuel combustion is usually required to reheat the compressed air to generate power efficiently. This leads to reliance on fossil fuels or other heat sources, decreasing overall system efficiency and increasing carbon footprint.

- Because the thermal energy is not captured and reused, diabatic CAES systems have lower round-trip efficiencies, generally below that of adiabatic systems.

Thermal Energy Management in Adiabatic CAES

- Adiabatic CAES systems capture the heat generated during compression and store it internally in thermal energy storage media such as solids (concrete, stone), fluids (hot oil, molten salts), or packed beds.

- This stored thermal energy is then returned to the compressed air during expansion to reheat it, eliminating the need for external fuel sources to provide heat.

- Theoretically, adiabatic CAES efficiency approaches 100% if heat loss is eliminated through perfect insulation. In practice, modern adiabatic systems achieve round-trip efficiencies around 70% or higher due to effective high-temperature thermal energy storage technologies.

- Thermal energy storage mediums and heat exchange fluids are carefully selected based on temperature ranges, containment viability, and heat loss characteristics to optimize performance.

- Innovations focus on low-cost and high-capacity thermal storage techniques to efficiently capture and reuse compression heat, boosting system effectiveness and reducing emissions compared to diabatic systems.

Summary Comparison

| Feature | Diabatic CAES | Adiabatic CAES |

|---|---|---|

| Heat from compression | Released to environment | Captured and stored in thermal storage medium |

| Heat reuse during expansion | Requires external heat source (e.g., fuel) | Uses stored heat to reheat air, no external fuel needed |

| Thermal energy storage | Not used | Integral part of system (solids, fluids, packed beds) |

| Efficiency (round-trip) | Lower (due to heat loss and fuel use) | Higher (~70% or more) with advanced thermal storage |

| Environmental impact | Higher due to fuel combustion | Lower carbon footprint, more renewable-friendly |

In essence, adiabatic CAES systems manage thermal energy by capturing and reusing compression heat, substantially improving efficiency and sustainability, while diabatic systems lose this heat and rely on extra fuel to compensate, making them less efficient and more carbon-intensive.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-thermal-energy-management-differ-between-diabatic-and-adiabatic-caes-systems/