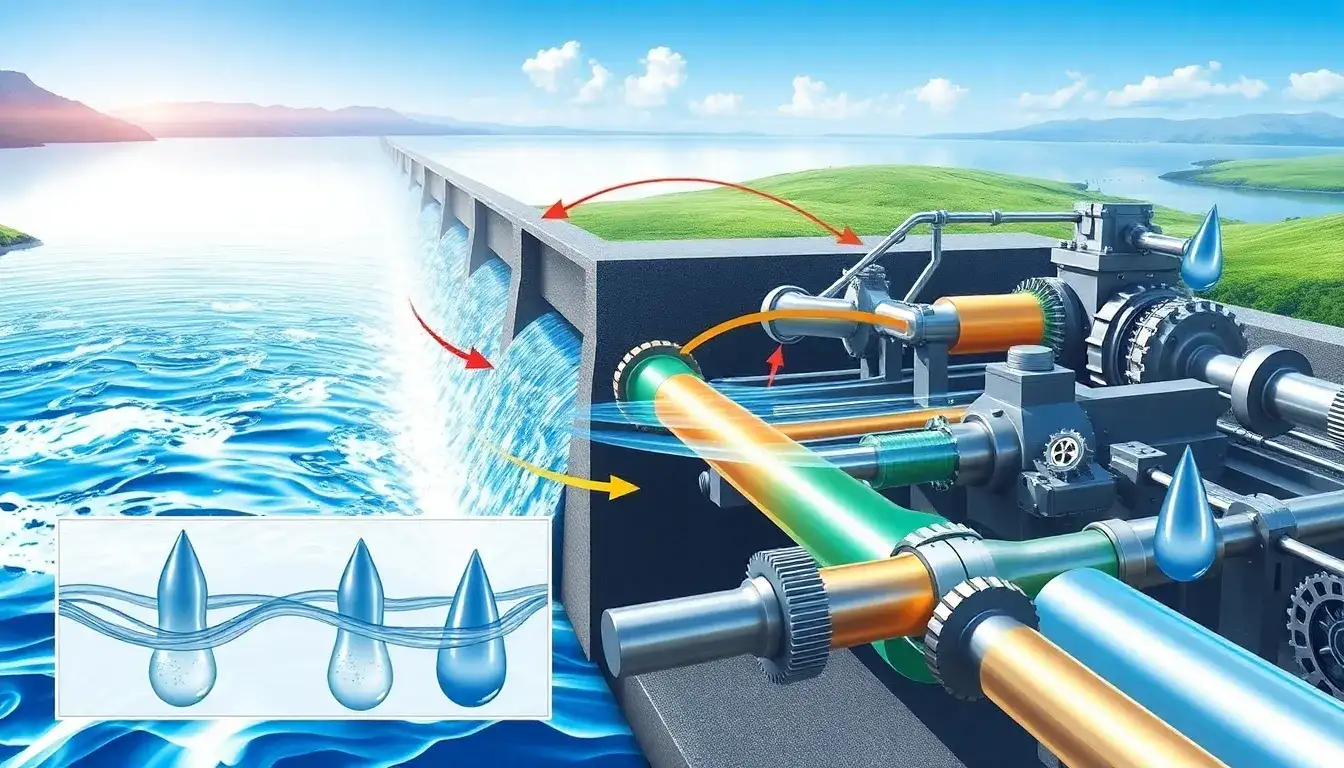

The viscosity of water directly influences friction losses in pumped hydroelectric plants by affecting the resistance to flow within pipes and conduits. Higher viscosity means the fluid resists flowing more, which increases friction loss and pressure drops along the pipeline.

How Viscosity Affects Friction Losses

- Viscosity and Flow Resistance: Viscosity is a measure of a fluid’s internal resistance to flow. In a pumped hydroelectric system, water with higher viscosity requires more energy (or head) to pump through pipes due to greater frictional resistance between the moving fluid layers and the pipe walls.

- Friction Loss Definition: Friction loss refers to the loss of pressure (or head) resulting from the frictional forces opposing fluid motion inside pipes or ducts. It increases with increasing viscosity because more force opposes the water’s movement.

- Flow Regime Influence: The relationship between viscosity and friction loss is also dependent on whether the flow is laminar or turbulent. In laminar flow (typically with very viscous fluids or low flow rates), friction loss can be precisely described by the Hagen–Poiseuille equation, which shows a direct proportionality between viscosity and pressure loss. In turbulent flow, which usually occurs in hydroelectric plants with water, friction loss is more complex but still increases with viscosity.

- Effect on Pumping Efficiency: Increased viscosity leads to higher frictional losses, reducing the efficiency of pumps used to move water in pumped hydro plants. Pumps require more power to overcome these losses, which results in increased energy consumption and possibly higher operational costs.

Specific Implications for Pumped Hydroelectric Plants

- Water viscosity at typical operating temperatures for hydro plants is relatively low, so friction losses due solely to viscosity are usually moderate but still crucial for precise energy calculations.

- As friction loss increases due to higher viscosity or other factors (roughness, pipe diameter, flow velocity), the pumps need to generate more head, affecting the overall efficiency and energy consumption of the hydroelectric system.

- The design and selection of pumps for hydro plants consider water viscosity to ensure pumps operate efficiently, minimizing losses and mechanical strain.

Summary Table: Viscosity Effects on Friction Loss

| Factor | Effect of Increased Viscosity | Impact on Pumped Hydro Plants |

|---|---|---|

| Flow resistance | Increases frictional resistance to flow | More energy required to pump water |

| Friction loss (pressure drop) | Increases proportionally with viscosity in laminar flow; complex in turbulent flow | Higher pumping head and power consumption |

| Pump efficiency | Decreases with increasing viscosity | Pump may need to be derated or redesigned |

| Energy consumption | Increases due to overcoming higher losses | Higher operational costs |

In essence, while water’s low viscosity keeps friction losses manageable, any increase in viscosity—due to temperature changes or impurities—raises friction losses, requiring more pumping power in pumped hydroelectric plants and thus reducing overall system efficiency.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-viscosity-of-water-affect-friction-losses-in-pumped-hydroelectric-plants/