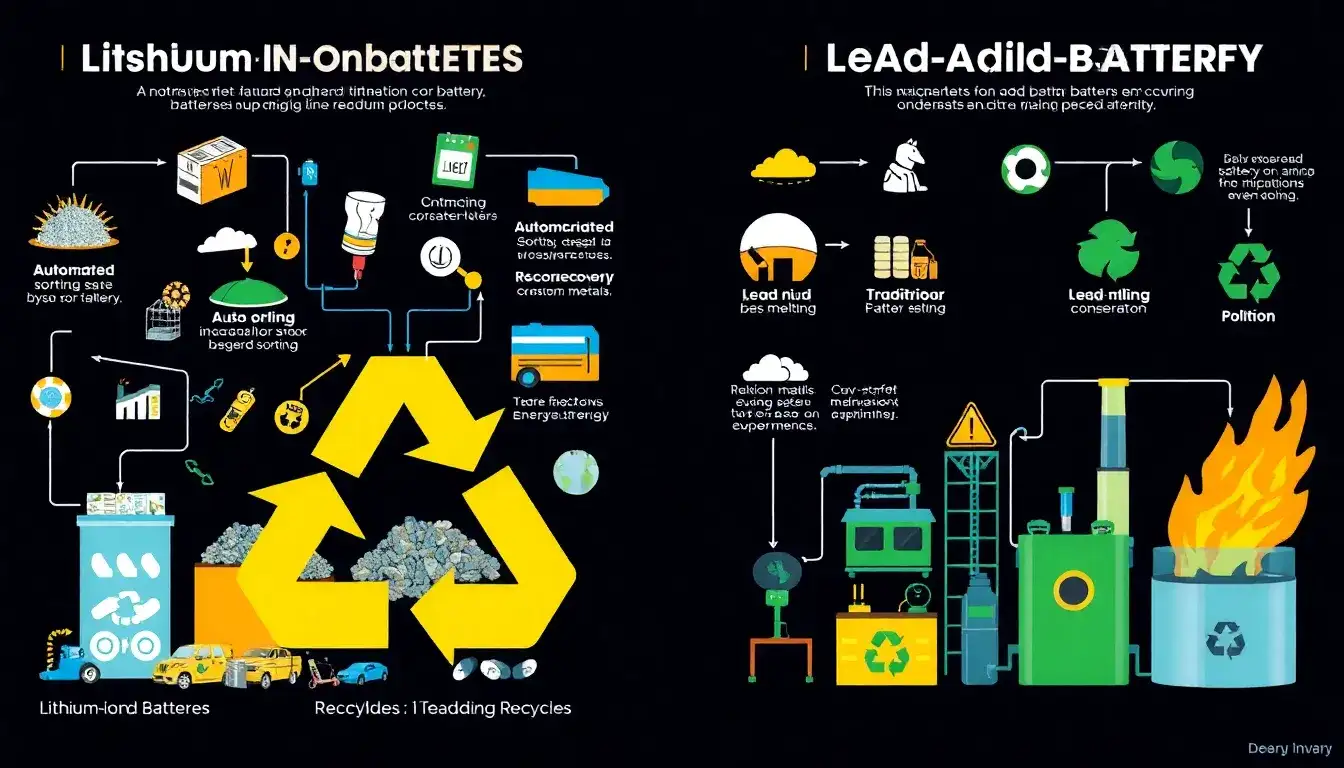

Recycling of Lithium-ion Batteries vs. Lead-acid Batteries

The recycling processes for lithium-ion batteries and lead-acid batteries differ significantly in complexity and efficiency. Here’s a comparison of the two:

Complexity and Efficiency

- Lithium-ion Batteries: Lithium-ion battery recycling is complex due to their diverse materials and chemistries (e.g., NMC, LMFP). The process involves collecting and sorting batteries, discharging, dismantling, and crushing them into a “black mass” for extraction of valuable metals like lithium, cobalt, nickel, and manganese. Traditional methods include hydrometallurgical and pyrometallurgical processes, which can be energy-intensive and costly. Newer methods, such as the BRAWS technology, aim to simplify and make recycling more environmentally friendly by using water and CO2.

- Lead-acid Batteries: Lead-acid batteries, on the other hand, are simpler to recycle due to their standardized composition and format. The recycling process involves pyrometallurgical methods where batteries are melted to extract lead, which can be reused to make new batteries efficiently and cost-effectively. The high recycling rate of lead-acid batteries is attributed to their uniformity and legal regulations that prohibit landfill disposal.

Recycling Rate

- Lithium-ion Batteries: Currently, only about 5% of lithium-ion batteries are recycled, largely due to the complex and expensive nature of the process.

- Lead-acid Batteries: In contrast, lead-acid batteries have a recycling rate of nearly 99% in the U.S., thanks to streamlined processes and stringent environmental regulations.

Environmental Impact

- Lithium-ion Batteries: Lithium-ion battery recycling is crucial to prevent toxic waste and maintain a sustainable supply of metals like lithium and cobalt, which are in limited supply. However, traditional recycling methods can produce toxic byproducts.

- Lead-acid Batteries: While lead-acid battery recycling helps conserve lead and prevent contamination, historic recycling practices have sometimes led to environmental pollution. Modern regulations have improved safety and efficiency.

Economic Considerations

- Lithium-ion Batteries: Currently, recycling lithium-ion batteries often costs more than extracting raw materials, making it less economically viable.

- Lead-acid Batteries: The economics of lead-acid battery recycling are favorable because the recovered lead is cost-competitive with primary lead, contributing to a closed-loop system where recycled lead is used to manufacture new batteries.

In summary, lead-acid battery recycling is more efficient and widely practiced due to standardized processes and regulatory support. Lithium-ion battery recycling faces challenges due to complex chemistries and high operational costs but is becoming increasingly important for sustainable energy management.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-recycling-process-of-lithium-ion-batteries-compare-to-that-of-lead-acid-batteries/