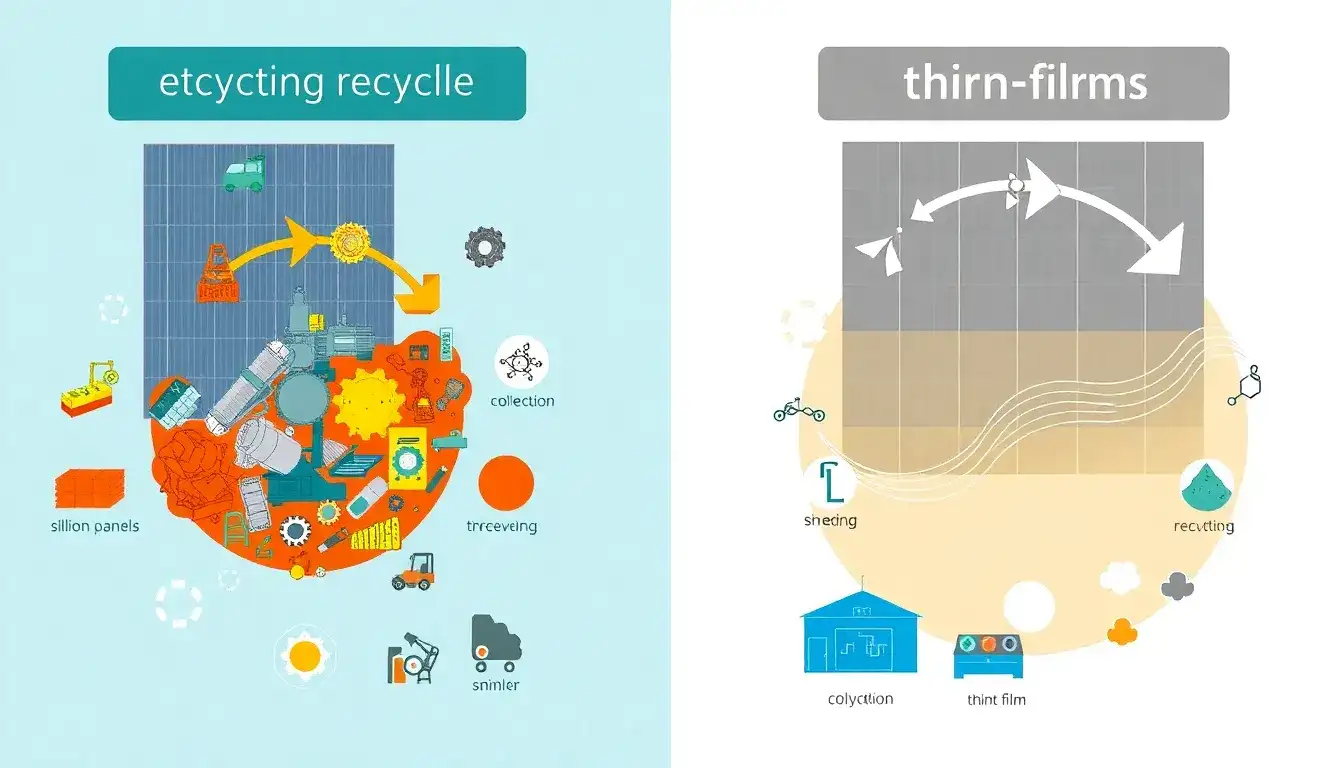

Silicon-Based Solar Panels

The recycling process for silicon-based panels begins with:

- Disassembly: Removing external components such as aluminum frames and copper cables. Aluminum frames are 100% reusable.

- Glass Separation: Glass is separated from the panel body using conveyor belts, with about 95% of it being reusable.

- Thermal Treatment: Panels are heated to 500°C to evaporate encapsulating plastics and facilitate the separation of silicon cells.

- Silicon Recovery: Silicon wafers are etched with acid and smelted for reuse, achieving an 85% recycling rate for silicon.

Thin-Film Solar Panels

The recycling process for thin-film panels involves:

- Shredding: Panels are first shredded into smaller pieces.

- Hammermilling: Shredded pieces are further reduced using a hammermill to break down lamination, allowing material separation.

- Separation and Refining: Unlike silicon-based panels, this process does not specifically focus on glass or aluminum separation but rather on breaking down the panel into its basic components for material recovery.

In summary, silicon-based panels are recycled with a focus on reusing glass, aluminum, and silicon, while thin-film panels require a more aggressive mechanical breakdown to separate materials.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-recycling-process-differ-between-silicon-based-and-thin-film-solar-panels/