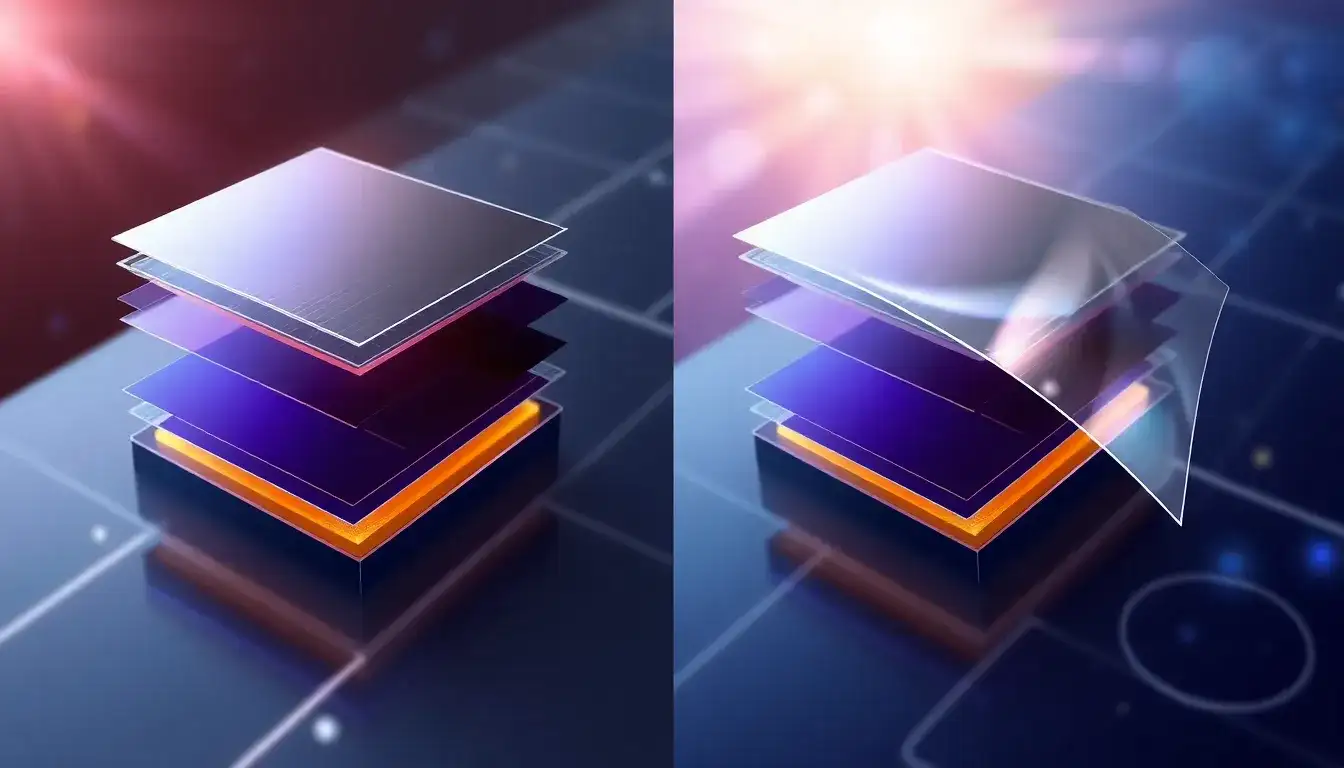

The protective film significantly improves the durability of perovskite solar cells (PSCs) by serving as a robust barrier against environmental stressors, particularly moisture and heat, which are known to degrade the perovskite materials and reduce solar cell efficiency.

How Protective Films Improve Durability

- Moisture Barrier: Perovskite layers are highly sensitive to moisture. Exposure to humidity causes decomposition of the perovskite active layer (commonly methylammonium lead iodide) into lead iodide, which blocks charge transport and diminishes efficiency. Protective films with very low water vapor transmission rates (WVTR) effectively block moisture ingress, preserving the perovskite structure and maintaining performance. For instance, a high-quality barrier film with a WVTR of 5.0 × 10⁻³ g/m²/day retained 84% of initial efficiency even after 2,000 hours in 85°C and 85% relative humidity conditions—a substantial improvement compared to weaker barriers that failed after 1,000 hours.

- Thermal Stability Enhancement: PSCs are typically vulnerable to high temperatures, which can degrade their components, especially the hole transport layer (HTL). Protective films combined with optimized cell chemistry improve thermal tolerance. For example, replacing conventional additives in the HTL with more thermally stable substitutes allowed PSCs to maintain over 85% efficiency after 1,000 hours at 85°C and 85% humidity. This approach increases the glass transition temperature of the HTL, preventing it from becoming nearly liquid and thus preserving structural integrity under heat.

- Chemical Stability via Protective Coatings: Protective films also chemically reinforce the perovskite surface by passivating defects and preventing ion migration. Innovations such as amidinium-based coatings are more thermally robust than conventional ammonium-based layers, resisting decomposition under heat and extending the operational lifetime by tripling the stability period before efficiency drops by 90%. This chemical passivation layer enhances both the durability and photovoltaic performance without sacrificing efficiency.

- Suppression of Ion Migration: A critical factor in PSC instability is the migration of halide ions within the perovskite. Protective films that include a well-designed barrier layer, such as a compact aluminum oxide layer grown via atomic layer deposition, reduce halide migration drastically. This ionic barrier extends the functional lifespan while maintaining high power conversion efficiency, with tests showing 90% efficiency retention after 1,000 hours at elevated temperatures and continuous illumination conditions.

- Long-Term Operational Stability: Beyond immediate environmental protection, specialized protective molecules—like sulfonium-based treatments—applied alongside barrier films can stabilize the perovskite film under continuous light exposure for thousands of hours. These treatments result in near-negligible efficiency loss even after 4,500 hours, suggesting protective films combined with molecular engineering can make PSCs competitive with silicon solar cells in both efficiency and durability.

Summary Table of Protective Film Benefits

| Protective Film Function | Effect on Durability | Example Outcome |

|---|---|---|

| Moisture barrier | Prevents perovskite degradation by humidity | 84% efficiency retained after 2,000 hours damp heat test |

| Thermal stability enhancement | Raises HTL glass transition temperature | >85% efficiency after 1,000 hours at 85°C/85% RH |

| Chemical passivation (amidinium) | Resists thermal decomposition, passivates defects | Tripled T90 lifetime, improved stability vs ammonium coatings |

| Ion migration suppression | Blocks halide ion movement | 90% efficiency retention after 1,000 h at 55°C under sunlight |

| Molecular stabilization (sulfonium) | Stabilizes under long-term light exposure | <1% efficiency loss after 4,500 hours operational tests |

Conclusion

Protective films improve perovskite solar cell durability primarily by encapsulating the sensitive perovskite layers against moisture, heat, and chemical degradation. High-quality barrier films minimize water vapor ingress, chemical passivation layers stabilize the perovskite material at the molecular level, and advanced coatings suppress ion migration. These combined protections result in significantly extended operational lifetimes and efficiency retention, bringing PSCs closer to commercial viability as a cost-effective, high-efficiency renewable energy technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-protective-film-improve-the-durability-of-perovskite-solar-cells/