The operational mode of a pumped hydro storage (PHS) system significantly affects the maintenance schedule of its turbine runner, primarily due to the frequency of mode changes and the nature of the water flow. Here’s how different operational modes impact maintenance:

Operational Modes and Maintenance Considerations

-

Pumping Mode (Storage):

- Impact: During the pumping phase, the turbine operates as a pump, which can introduce different stresses and wear compared to the generating mode. The pumping mode typically involves low-cost, surplus electricity to lift water to the upper reservoir.

- Maintenance Considerations: Regular checks are needed for the pump’s seals, bearings, and impeller conditions to ensure efficiency and prevent damage.

-

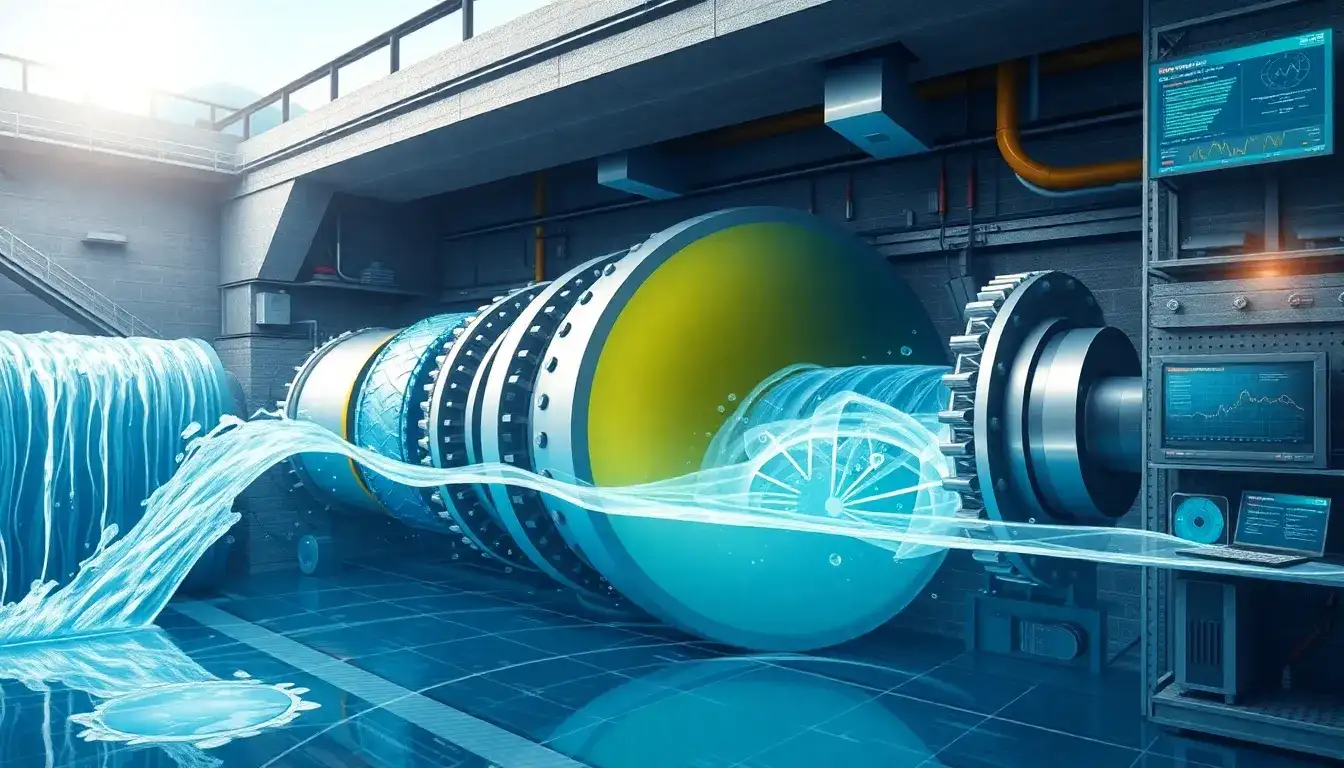

Generating Mode (Power Production):

- Impact: In the generating mode, water is released from the upper reservoir to flow through the turbine, generating electricity. This mode involves high-speed operation and can cause different types of wear on the turbine runner, such as erosion or cavitation.

- Maintenance Considerations: Frequent inspections are necessary to ensure the turbine runner is not damaged by cavitation or erosion. The runner and other moving parts need periodic cleaning and balancing to maintain efficiency and prevent vibrations.

-

Mode Switching:

- Impact: The frequency of switching between pumping and generating modes can increase the stress on the turbine. Frequent starts and stops can lead to thermal stress, which affects mechanical components like bearings and seals.

- Maintenance Considerations: Regular monitoring of the turbine’s condition during mode switching is crucial. This may involve checking for excessive wear on mechanical components or signs of thermal stress.

-

Variable Speed Operation:

- Impact: Innovations like variable speed turbines offer better efficiency and flexibility but may introduce complexities in maintenance due to more sophisticated control systems.

- Maintenance Considerations: Specialized maintenance schedules focusing on the speed control systems and their interactions with the turbine are necessary. This may include software updates and checks on mechanical couplings.

Conclusion

The maintenance schedule of a PHS turbine runner is influenced by its operational modes, focusing on wear, stress, and the complexity of mechanical and electrical systems. Proper maintenance planning reduces downtime and ensures optimized performance across different modes. Regular inspections, preventive maintenance, and considering the impact of mode changes are critical to extending the turbine’s lifespan and efficiency.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-operational-mode-of-a-pumped-hydro-storage-system-affect-the-maintenance-schedule-of-its-turbine-runner/