How does the nitrogen in the die casting machine store energy?

1. Nitrogen acts as a medium for energy storage, 2. It enhances the cooling process, 3. High-pressure applications allow for efficient energy transfer, 4. Use of nitrogen leads to improved machine efficiency.

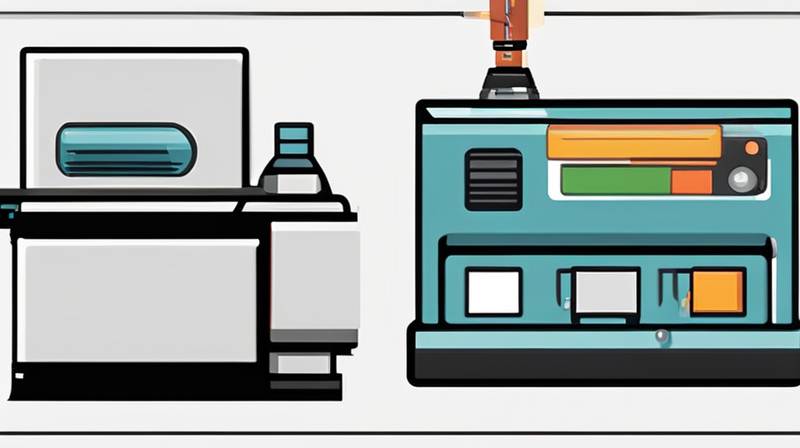

Nitrogen plays a crucial role in the die casting machine by storing energy primarily through its properties at various pressures and temperatures. In die casting, nitrogen is used in gas-assist technology, where it can compress and expand to modulate pressure during the cooling and injection processes, contributing to enhanced efficiency and precision. This energy storage mechanism allows for more effective thermal management, ensuring better production quality and lower operational costs. By understanding how nitrogen contributes to energy storage and management in die casting, manufacturers can optimize their processes for optimal performance and output.

NITROGEN AS AN ENERGY STORAGE MEDIUM

Nitrogen possesses unique qualities that make it an excellent medium for energy storage in die casting procedures. The primary factor involves the ability of nitrogen to exist in both high-pressure and low-pressure states. Under high-pressure conditions, nitrogen is compressed, storing a significant amount of energy. This energy can be released at a controlled rate during the casting cycle, allowing for a more efficient process. The valving and control mechanisms implemented in die casting machinery ensure that nitrogen is introduced into the system at optimal times, which maximizes the energy transfer effectiveness.

The storage potential of nitrogen also finds applications in temperature regulation within the die casting environment. When nitrogen expands after being released from a high-pressure state, it absorbs heat, leading to a cooling effect. This phenomenon helps regulate temperatures around the molten metal, ensuring that it solidifies at the correct rate and consistency. This careful management of energy and temperature is crucial for achieving dimensional accuracy and minimizing defects in the final product, which ultimately translates to higher quality and improved profitability for manufacturers.

ENHANCEMENT OF COOLING PROCESSES

The efficiency of cooling processes in die casting machines is pivotal for maintaining product quality. Nitrogen’s thermal conductivity and heat absorption capabilities are essential in providing a rapid cooling effect. When introduced into the die, nitrogen effectively draws heat away from the surrounding areas, thereby preventing overheating of the components and maintaining optimal conditions for casting. This rapid cooling not only hastens cycle times but also enhances the surface finish and structural integrity of the cast components.

In addition to its cooling properties, the use of nitrogen helps minimize oxidation and gas inclusions in the cast material. This is particularly crucial when dealing with sensitive alloys that may be reactive to atmospheric conditions. By maintaining an inert environment, nitrogen acts as a safeguard against defects that can occur due to oxygen exposure. Consequently, this translates to fewer reworks and rejects, thereby improving the overall productivity and yield of die casting operations.

HIGH-PRESSURE APPLICATIONS IN DIE CASTING

In the realm of die casting, the deployment of nitrogen under high-pressure conditions offers numerous advantages. High-pressure nitrogen systems enable better injection velocities and more uniform filling of molds. The ability to precisely control the energy stored in the nitrogen allows for aggressive injection rates, resulting in less turbulence and air entrapment within the molten metal. This control plays a significant role in enhancing the mold’s fill, ensuring that every crevice of the die is adequately filled with the material.

Moreover, the energy release from nitrogen during the filling process can lead to a notable increase in production efficiency. Manufacturers gain from quicker cycle times while not compromising on quality. The integration of high-pressure nitrogen technology encourages innovation in die casting machinery, facilitating improvements in design, efficiency, and adaptability to various materials. As manufacturers strive for higher productivity and reduced costs, high-pressure nitrogen systems will continue to be pivotal in achieving these objectives.

IMPROVEMENTS IN MACHINE EFFICIENCY

The use of nitrogen in die casting machines correlates strongly with enhanced operating efficiency. Efficient energy management plays a vital role in reducing the overall operational costs associated with the casting process. By utilizing nitrogen, manufacturers can achieve lower energy consumption and reduced wear on machinery components due to less frequent and less aggressive cooling cycles. This longevity translates into better return on investment for equipment and resources.

Furthermore, the incorporation of nitrogen technology encourages innovative design patterns in machinery. With a focus on efficiency, manufacturers can re-engineer their machines to accommodate nitrogen systems, optimizing layouts and workflows. Consequently, this leads to reduced downtime, minimized maintenance requirements, and the potential for automation in the workflow. As sulfur enters a more dynamic era, the drive for greater efficiency in die casting through nitrogen integration sets a benchmark that future technologies will likely emulate.

FAQs

HOW DOES NITROGEN COMPARE WITH OTHER GAS ASSIST TECHNOLOGIES IN DIE CASTING?

While numerous gases like carbon dioxide and argon have been explored for assistive technology in die casting, nitrogen remains the most favored option. Nitrogen’s inert characteristics prevent unwanted reactions with molten metals, while its cost-effectiveness and abundance make it an economically viable choice. Additionally, nitrogen’s maximizing cooling capabilities and energy storage attributes further set it apart from alternatives. Therefore, it supports reduced cycle times, high-quality outcomes, and overall process efficiency, positioning it as a preferred medium in the industry.

WHAT ARE THE ENVIRONMENTAL BENEFITS OF USING NITROGEN IN DIE CASTING?

Utilization of nitrogen in die casting aligns with environmental sustainability due to its inert nature. Since nitrogen does not create emissions during typical die casting operations, it contributes to a decreased carbon footprint. Furthermore, the precise control over the manufacturing process facilitated by nitrogen helps reduce waste associated with defective products. As industries shift towards greener practices, the efficiency that nitrogen provides also assists in decreasing energy consumption, thereby maximizing resource use while minimizing environmental impacts.

CAN NITROGEN BE UTILIZED IN OTHER MANUFACTURING PROCESSES SIMILAR TO DIE CASTING?

Absolutely, nitrogen can be deployed across a variety of manufacturing processes similar to die casting. Its properties make it suitable for applications involving metals, plastics, and composites that require inert environments. Industries, such as automotive, aerospace, and electronics, can benefit from nitrogen’s energy storage capabilities and thermodynamic control features. Thus, manufacturers in different sectors can adopt nitrogen technology for enhancing product quality, lowering operational costs, and achieving better production outcomes.

Utilizing nitrogen in die casting machinery offers extensive benefits that permeate various aspects of the manufacturing process. From energy storage capabilities to enhancements in cooling procedures, nitrogen not only improves product quality but also facilitates significant efficiencies in operation. As industries worldwide continually strive for reductions in operational costs while maximizing output, nitrogen emerges as a solution that meets such demands with exceptional effectiveness. Moreover, the inert nature of nitrogen aids in maintaining a more environmentally-friendly production process that aligns with global sustainability goals. The flexibility and applicability of nitrogen extend beyond die casting; industries reliant on similar manufacturing technologies can incorporate nitrogen for analogous advantages. Therefore, it is essential for manufacturers to recognize the vital role that nitrogen can play not solely in die casting but also in broader manufacturing operations, as the industry moves towards a future that aims for efficiency, quality, and sustainability in every aspect possible.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-nitrogen-in-the-die-casting-machine-store-energy/