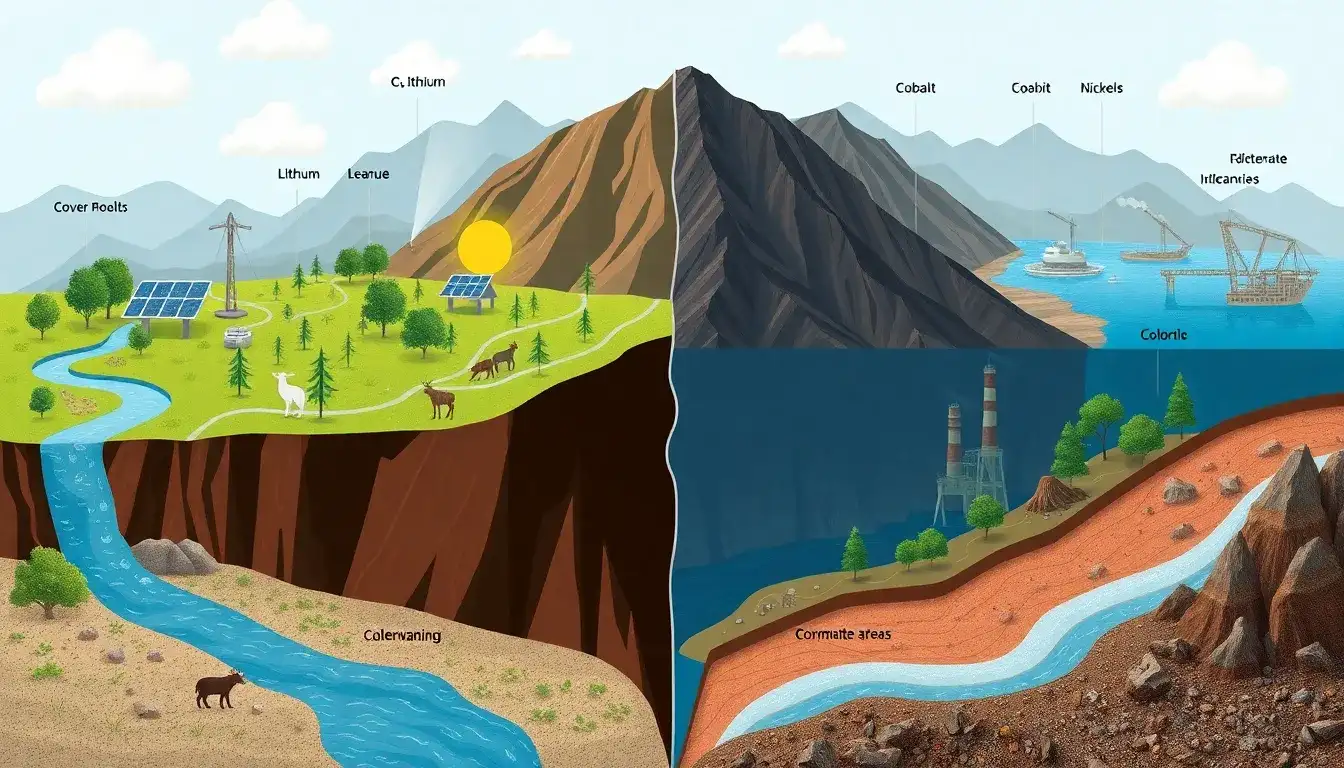

The environmental impact of mining processes for different battery chemistries

varies significantly based on the type of battery and its components. Here’s a comparison of the main chemistries:

Lithium-Ion Batteries

Lithium-ion batteries, widely used in electric vehicles and portable electronics, rely on lithium, cobalt, nickel, and other metals. The mining of these materials has several environmental impacts:

- Lithium Mining: Lithium is primarily mined through either hard rock mining or brine extraction. Hard rock mining can lead to significant land disruption and high energy use. Brine extraction is more cost-effective but consumes large amounts of water and can disrupt local ecosystems.

- Cobalt Mining: Cobalt mining is a significant source of pollution and social concerns, particularly in the Democratic Republic of Congo, where child labor issues are prevalent.

- Nickel Mining: Nickel production is energy-intensive and contributes to high greenhouse gas emissions, mainly due to electricity consumption during mining and refining.

Lithium Iron Phosphate (LFP) Batteries

- Environmental Impact: LFP batteries use less energy-intensive materials compared to nickel-based chemistries. They involve lower GHG emissions due to less reliance on high-carbon metals like cobalt and nickel.

- Sustainability: LFP batteries have a reduced environmental footprint as they do not require cobalt or nickel, making them a more sustainable option compared to other lithium-ion chemistries.

Comparison Summary

| Battery Chemistry | Primary Metal Sources | Environmental Impact Notes |

|---|---|---|

| Nickel-Cobalt-Lithium (NCL) | Lithium, Cobalt, Nickel | High GHG emissions, water-intensive, habitat disruption, and social concerns. |

| Lithium Iron Phosphate (LFP) | Lithium, Iron Phosphate | Lower GHG emissions, less water-intensive, fewer social concerns. |

In conclusion, while lithium-ion batteries with nickel and cobalt have higher environmental impacts due to their metal extraction processes, alternatives like LFP offer a more sustainable option with lower emissions. The shift towards cleaner, less resource-intensive chemistries is crucial for reducing the environmental footprint of battery production.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-mining-process-for-different-battery-chemistries-compare-in-terms-of-environmental-impact/