The location of a liquid air energy storage (LAES) plant can significantly affect its efficiency by influencing the availability of low-grade waste heat or cold, which can be crucial for enhancing the thermal efficiency of the system.

Key Factors Influencing Efficiency

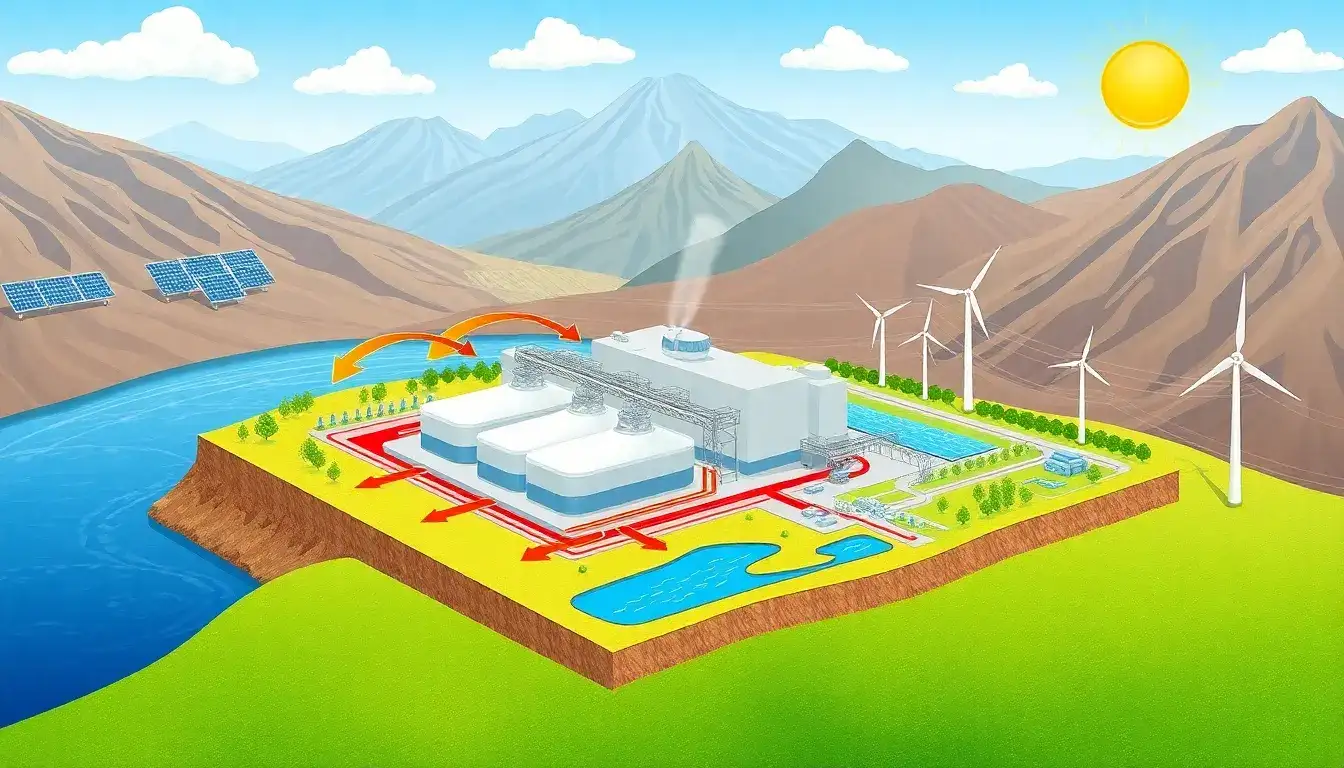

- Access to Low-Grade Waste Heat or Cold: LAES plants can utilize low-grade waste heat or cold from nearby industrial processes or renewable energy sources to improve their efficiency. Locations near industrial sites, like steel mills or biomass plants, can benefit from this waste heat to boost efficiency above 70%.

- Proximity to Energy Demand Centers: Situating LAES plants near the point of energy demand can reduce transmission losses and enhance system overall efficiency by minimizing power dissipation over long transmission lines.

- Environmental Conditions: Although not explicitly stated, environmental conditions such as temperature can influence the efficiency of refrigeration and liquefaction processes. Generally, however, LAES can be built anywhere without significant environmental constraints, making location less critical for these factors.

Efficiency Ranges

- Standalone LAES: Typically achieves around 50–60% efficiency.

- LAES with Waste Heat Utilization: Can achieve efficiencies of over 70% when waste heat is incorporated into the process.

Conclusion

The efficiency of a LAES plant is significantly affected by its ability to utilize waste heat or cold, which is often dependent on its location relative to industrial processes or waste heat sources. Therefore, strategically locating these plants near such sources can enhance their efficiency.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-location-of-a-liquid-air-energy-storage-plant-affect-its-efficiency/