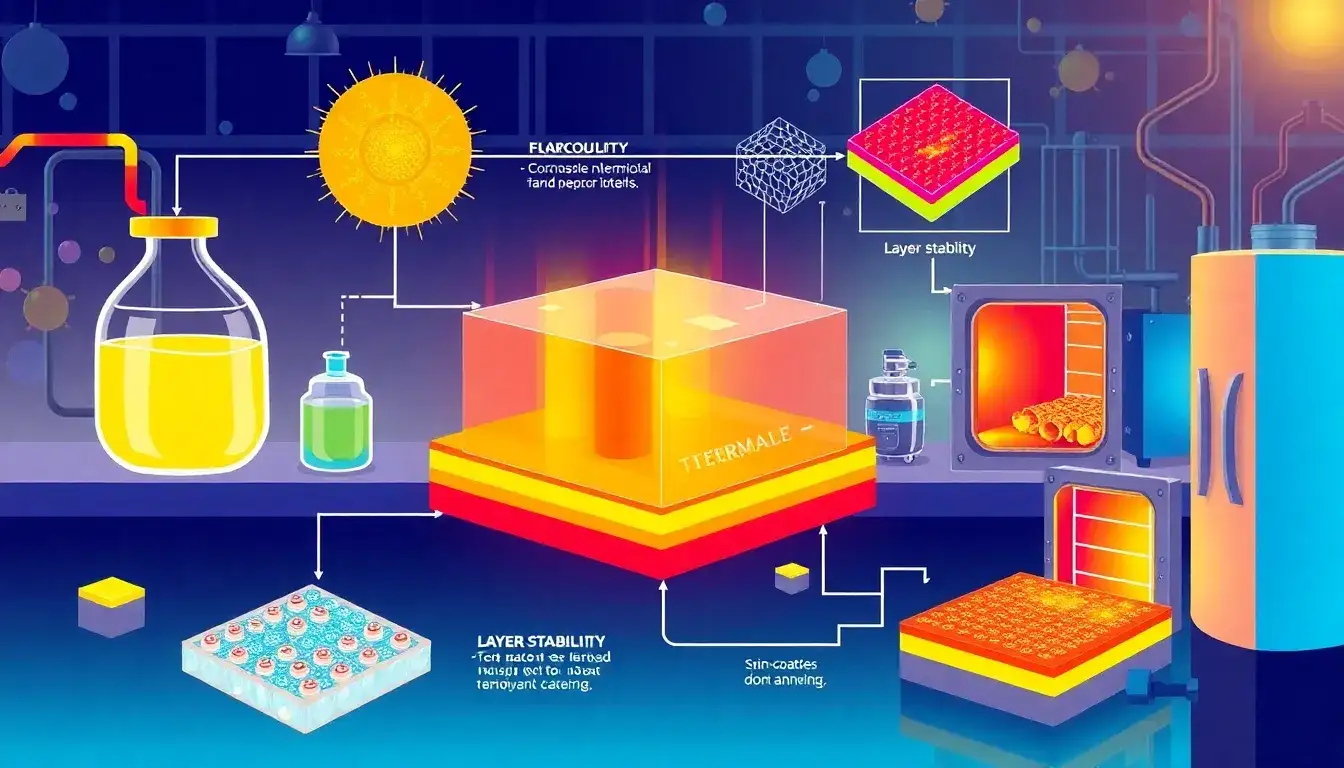

How Fabrication Influences Thermal Stability

1. Crystallization Quality and Film Formation

The method used to form the perovskite layer—such as spin-coating, vapor deposition, or electrodeposition—determines the quality of the perovskite crystal structure. Proper crystallization is critical because well-formed perovskite crystals with fewer defects resist degradation at elevated temperatures better. Poor crystallization leads to defects and grain boundaries that act as failure points under thermal stress, reducing thermal stability.

2. Layer Uniformity and Interface Quality

Fabrication techniques influence the uniformity and coverage of the perovskite and adjacent layers (electron transport, hole transport layers). Uneven layers or poor interfaces can cause localized heating and facilitate degradation mechanisms. Simplified fabrication processes that co-deposit multiple layers (such as combining hole-transport layer and perovskite deposition in a single step) have shown promise in creating more robust interfaces, enhancing overall thermal resilience.

3. Heating and Annealing Steps

Thermal treatment during fabrication (annealing) stabilizes the perovskite film by driving off solvents and promoting crystal growth. The temperature and duration of heating affect the material’s phase stability. Optimized annealing leads to better crystallinity and moisture resistance, both important for thermal stability. However, excessive heating can cause decomposition or unwanted phase changes, undermining stability.

4. Material Composition and Precursor Mixing

The choice of precursor salts and their mixing method impact the final perovskite composition and defect density. Tailored precursor solutions and controlled mixing during fabrication help in forming stable perovskite phases that withstand higher temperatures without degradation.

5. Simplification and Scalability of Fabrication

Advanced approaches that reduce fabrication complexity—like simultaneous deposition of multiple functional layers—can reduce manufacturing steps that could introduce defects or inconsistencies. This simplification potentially improves batch-to-batch consistency, which is essential for thermal stability and long-term device reliability.

Summary Table: Fabrication Factors Affecting Thermal Stability

| Fabrication Aspect | Impact on Thermal Stability |

|---|---|

| Crystallization Method | Better crystal quality improves resistance to thermal stress |

| Layer Uniformity | Uniform layers reduce hotspots and degradation pathways |

| Heating/Annealing | Proper annealing enhances phase stability, avoids decomposition |

| Precursor Composition | Stable chemical composition resists thermal breakdown |

| Process Simplification | Fewer fabrication steps reduce defects, improve reproducibility |

In conclusion, the fabrication process affects the thermal stability of perovskite solar cells mainly by influencing crystal quality, layer uniformity, material composition, and the integrity of interfaces, all of which determine the cell’s ability to withstand heat without degradation. Innovations that simplify the coating and annealing steps while ensuring high-quality film formation are critical for enhancing thermal stability and commercial viability of perovskite solar cells.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-fabrication-process-affect-the-thermal-stability-of-perovskite-solar-cells/