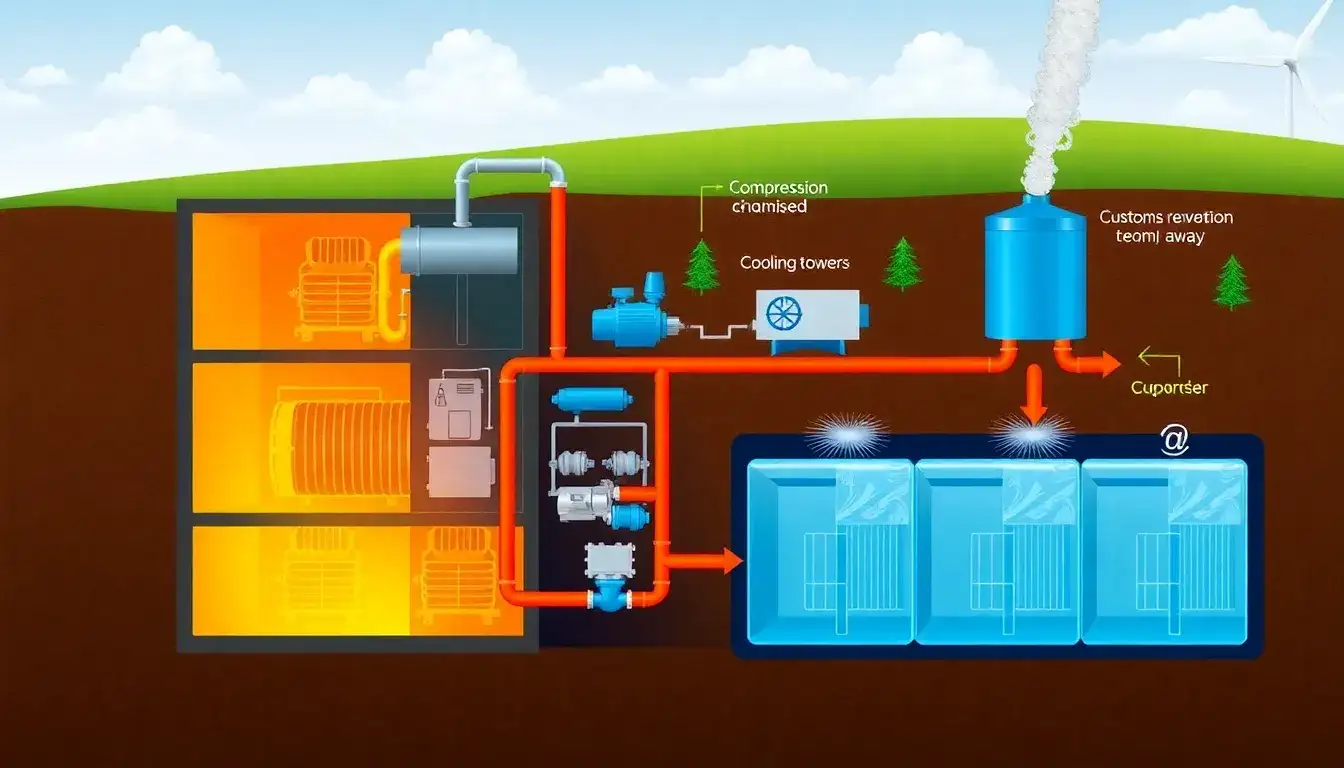

The expansion process in Compressed Air Energy Storage (CAES) systems inherently removes heat through thermodynamic work extraction, but heat management during this phase depends on the system design:

- Thermodynamic Cooling During Expansion:

When compressed air expands in turbines, its temperature drops due to adiabatic expansion (energy conversion into mechanical work). This natural cooling effect is a direct consequence of the air performing work on the turbine blades. - Preheating and Heat Recovery:

- Diabatic CAES: In non-adiabatic systems, external heat sources (e.g., natural gas combustion) counterbalance cooling by reheating air before expansion.

- Adiabatic CAES (A-CAES): Stores compression heat during energy storage and uses it to preheat air before expansion. The heat is not removed during expansion itself—instead, it mitigates temperature drop to improve efficiency. Thermal energy storage (TES) transfers heat to the air via heat exchangers prior to expansion.

- Heat Exchangers in Multi-Stage Systems:

Modern designs (e.g., AA-CAES-CHP) use intercoolers and aftercoolers during compression to extract heat. During expansion, stored heat is reapplied through heat exchangers, maintaining higher temperatures to optimize turbine performance without active heat removal during the expansion stage.

Thus, the expansion process itself does not actively remove heat—instead, heat management occurs during pre-expansion heating or prior compression phases to counteract the natural cooling effect of expansion.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-expansion-process-in-caes-systems-remove-heat/