The degradation of electrolytes in flow batteries significantly impacts their performance, particularly in terms of capacity, efficiency, and lifespan. This degradation primarily occurs through mechanisms such as crossover and chemical reactions that reduce the active species’ availability in the electrolyte.

Key Factors in Electrolyte Degradation

- Crossover Effects

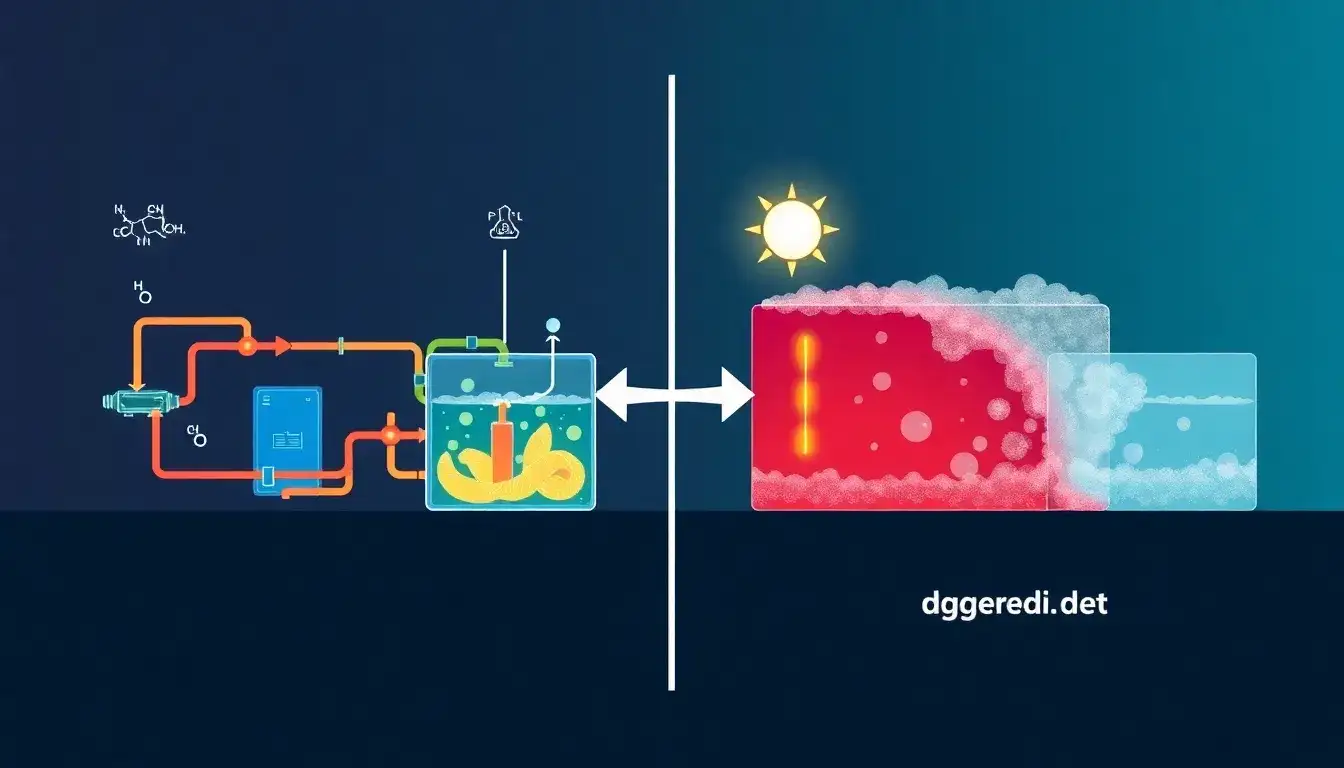

Flow batteries typically consist of two separate tanks of liquid electrolytes, each containing unique active species that undergo electrochemical reactions. A key challenge is the phenomenon known as crossover, where some active species from one tank can unintentionally migrate through the membrane to the opposite tank. This results not only in a loss of active materials but can also lead to unintended chemical reactions between the exhausted species, effectively discharging the battery even when it’s not in use. As a result, the overall energy capacity and efficiency of the battery diminish. - Reduction in Capacity and Efficiency

As electrolytes degrade, the flow battery’s capacity fades. This degradation translates into lower efficiency during charge and discharge cycles, which is crucial for applications that demand reliable and consistent power output. For instance, the internal reactions and loss of active material can lead to performance declines, reducing the battery’s ability to deliver energy effectively over time. - Chemical Stability of Electrolytes

The choice of electrolytes is critical in managing degradation rates. While vanadium-based flow batteries are preferred in many applications due to their stability and minimal degradation, other organic or less stable electrolytes may experience faster degradation due to side reactions, such as dimerization and disproportionation. The chemical stability of the active materials directly influences the longevity and performance consistency of the battery.

Implications for Performance

- Lifespan and Maintenance

The degradation process necessitates regular maintenance to restore lost capacity. This might involve replacing the electrolyte or adjusting the oxidization states of active species through chemical remediation methods. Although flow batteries are designed for easier access to components compared to traditional solid-state batteries, ongoing maintenance still incurs costs and operational downtime. - Economic Impact

The degradation of electrolytes can lead to increased operational costs due to the need for remediation and replacement, directly affecting the levelized cost of electricity (LCOE) from these systems. While flow batteries can offer competitive costs at scale, their economic viability diminishes if electrolyte degradation is not effectively managed. - Performance Metrics

The overall performance metrics of flow batteries, such as cycle life and energy efficiency, can be severely impacted by electrolyte degradation. Vanadium flow batteries, for example, have been shown to support over 20,000 cycles with minimal degradation, illustrating the importance of stable electrolytes in achieving high performance over extended periods.

In summary, the degradation of electrolytes in flow batteries is a critical factor that impacts their overall performance. It affects capacity, efficiency, maintenance requirements, and economic viability, emphasizing the need for ongoing research into stable electrolyte solutions and improved battery designs to mitigate these effects.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-degradation-of-electrolytes-in-flow-batteries-impact-their-overall-performance/