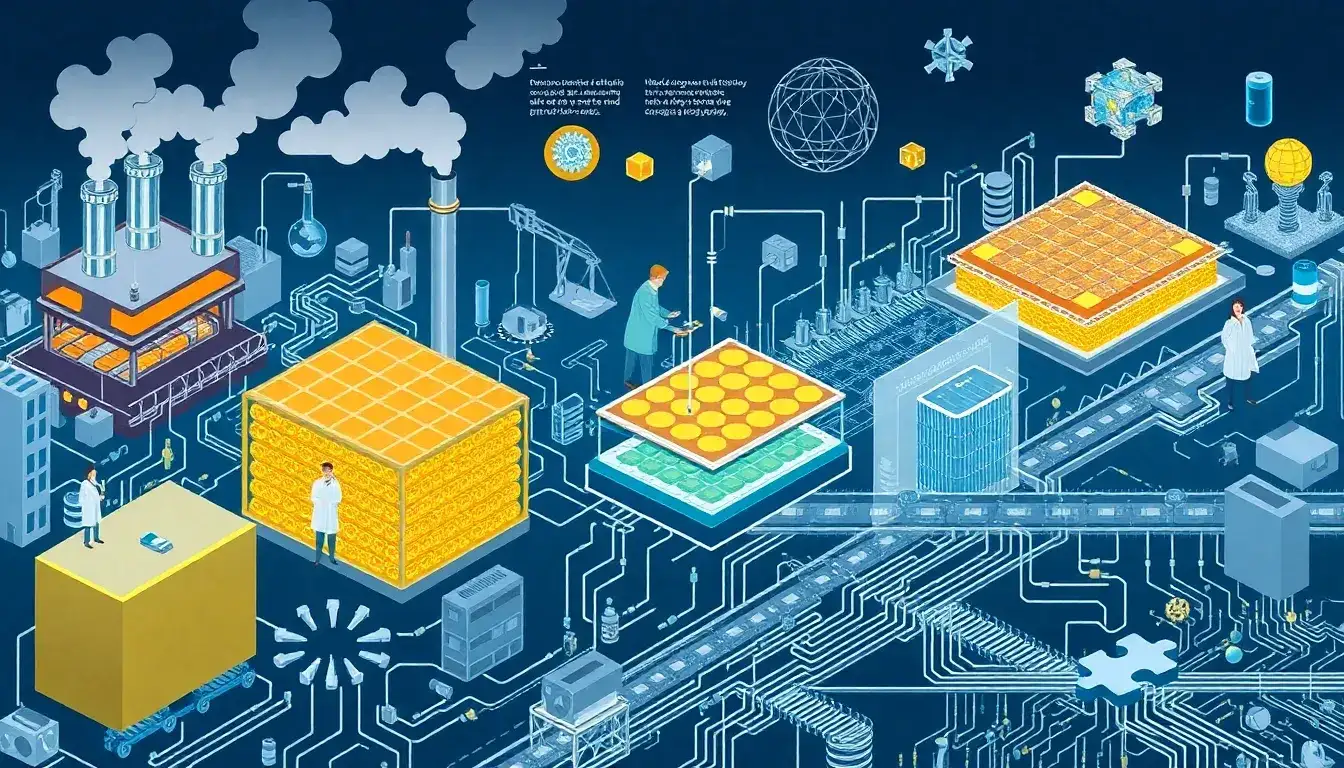

The complexity of manufacturing solid-state batteries creates significant scalability challenges by introducing high costs, technical barriers, and production inefficiencies that hinder mass adoption. Here’s how these factors interplay:

1. Advanced Material Requirements

Solid-state batteries rely on specialized electrolytes (sulfide- or oxide-based) that demand high ionic conductivity, thermal stability, and defect-free fabrication. These materials are costly and sensitive to environmental conditions, necessitating dry-room manufacturing to prevent degradation. Scaling production requires securing consistent material supplies and optimizing formulations to reduce costs, which remains a work in progress.

2. Precision Manufacturing Processes

Creating ultra-thin, uniform electrolyte layers (often <20 µm) requires cold sintering, thin-film deposition, or other high-precision techniques. These processes are slower and less forgiving than traditional battery manufacturing, with coating speeds needing optimization to balance quality and throughput. Even minor defects in electrolyte-electrode interfaces can lead to dendrite formation or high interfacial resistance, risking short circuits or reduced performance.

3. Infrastructure and Capital Costs

Scaling to gigawatt-hour production demands specialized equipment, skilled labor, and real-time quality monitoring systems. The transition from lab-scale to industrial production involves redesigning workflows and investing heavily in facilities, which increases financial risk. For example, slower coating speeds (e.g., 1 m/min vs. 100 m/min in traditional batteries) inflate machine and building costs per unit.

4. Supply Chain Immaturity

The lack of an established supply chain for solid electrolytes and compatible electrodes forces manufacturers to develop proprietary solutions, further delaying scalability. Recycling and repurposing infrastructure for these materials also lag behind conventional lithium-ion systems.

Cost Implications

At low production speeds (1 m/min), capital costs dominate due to underutilized equipment, while at higher speeds (100 m/min), material costs become the primary barrier. Pilot projects are now addressing these issues, with costs expected to drop as processes mature. However, achieving price parity with lithium-ion batteries remains a multiyear challenge.

In summary, the complexity of solid-state battery manufacturing manifests in higher costs, technical precision demands, and supply chain gaps, directly limiting scalability despite the technology’s potential advantages.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-the-complexity-of-manufacturing-solid-state-batteries-impact-their-scalability/