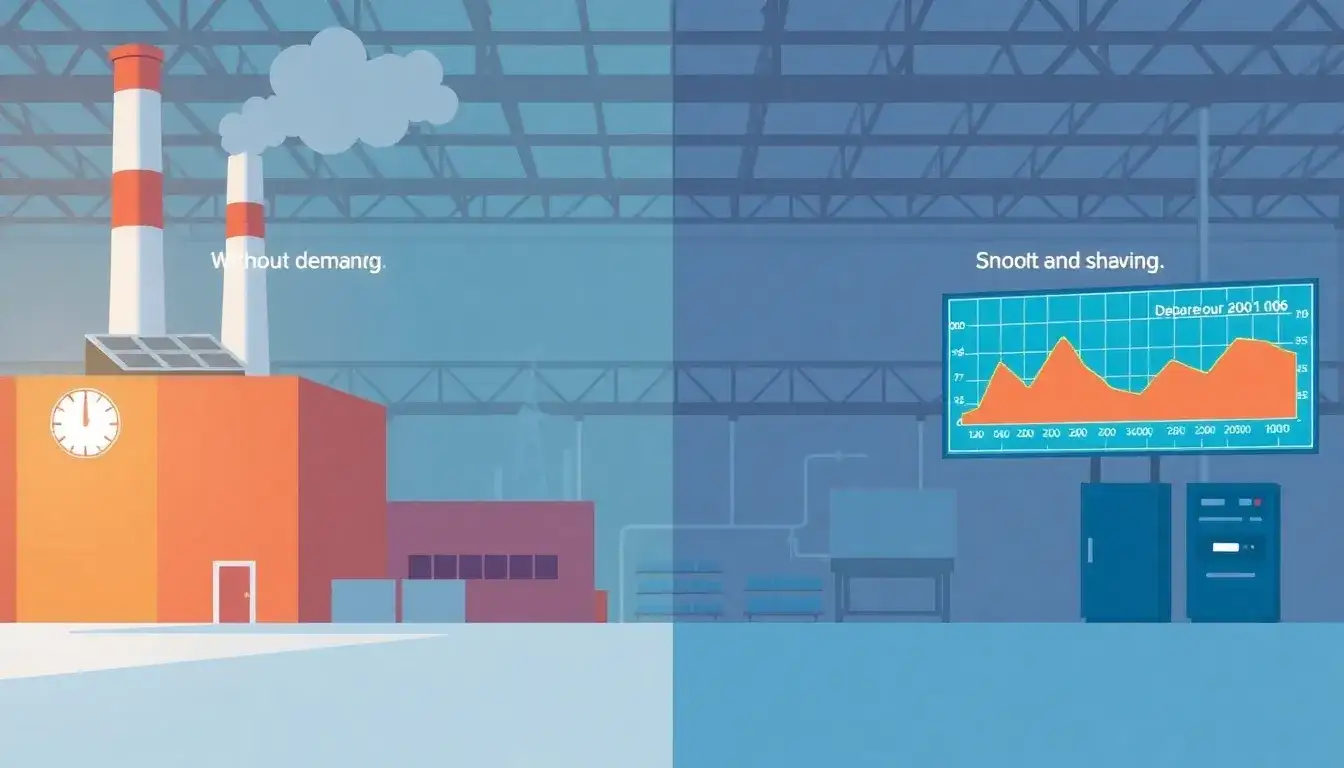

Peak shaving is a critical strategy used by industrial customers to reduce demand charges associated with high electricity usage during peak periods. This practice involves reducing or managing electricity consumption to avoid short-term spikes in demand, which are often the basis for calculating demand charges. Here’s how peak shaving helps:

How Peak Shaving Reduces Demand Charges

- Understanding Demand Charges: Demand charges are fees imposed by utility providers based on the highest rate of energy consumption during peak periods, typically measured in kilowatts (kW). These charges can account for a significant portion of an industrial customer’s electricity bill, often ranging from 30% to 70% of the total cost.

- Peak Shaving Strategy: Peak shaving reduces demand charges by minimizing the peak power consumption during these high-demand periods. It involves using energy storage systems, such as battery energy storage systems (BESS), to store energy during off-peak hours or when renewable energy sources like solar power are available.

- Operation of Peak Shaving:

- Energy Storage: During off-peak hours, the BESS charges from the grid or from renewable sources.

- Peak Periods: During peak hours when demand is high, the stored energy in the BESS is discharged to meet some of the facility’s energy needs. This reduces the amount of electricity drawn from the grid, thereby lowering the peak demand level.

- Automatic Management: Modern systems use AI-driven software to predict and manage these demand spikes, ensuring that the facility does not exceed a predetermined power threshold during peak periods.

Benefits of Peak Shaving for Industrial Customers

- Cost Savings: By reducing the peak demand from the grid, industrial customers can lower their demand charges significantly.

- Grid Stability: Peak shaving helps stabilize the grid by reducing the pressure on it during peak times, preventing potential outages.

- Flexibility and Reliability: Battery energy storage systems provide backup power during grid outages, ensuring continuous operation of critical equipment.

Suitable Applications

Peak shaving is particularly beneficial for industrial processes that require continuous operation and cannot shift their energy consumption to off-peak times. Examples include manufacturing facilities, data centers, and large HVAC systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-peak-shaving-help-reduce-demand-charges-for-industrial-customers/