1. Industrial energy storage systems are pivotal for the electrification of heavy machinery, primarily due to 1. the efficient management of energy supply and demand, 2. facilitating the integration of renewable energy sources, and 3. improving operational efficiency and providing backup power in case of outages.

A notable point is how these systems enhance the reliability and consistency of power supply, which is crucial for heavy machinery that operates continuously and requires stable energy inputs. Traditional fossil fuel-powered machines are gradually being replaced by electric alternatives, leading to increased demand for reliable energy storage solutions. Industrial energy storage systems, including batteries and flywheels, allow for excess energy generated during low-demand periods to be stored and utilized when needed, ensuring that operations can be maintained without interruption.

1. SIGNIFICANCE OF ENERGY STORAGE IN INDUSTRIAL OPERATIONS

In contemporary manufacturing and heavy industries, the transition from conventional energy sources to electrically operated machinery necessitates innovative methodologies for energy management. One of the key facilitators of this transition is industrial energy storage, a mechanism that helps harmonize energy distribution and consumption patterns. The implementation of energy storage solutions directly impacts operational efficiency, cost-effectiveness, and the overall sustainability profile of industrial operations.

By introducing energy storage systems, industries can counteract fluctuations in energy demand which is particularly critical for heavy machinery that often runs at high capacities for prolonged periods. With the capacity to store energy generated from renewable sources, businesses can optimize their operations during peak hours while reducing reliance on grid energy, which can be particularly costly.

Moreover, energy storage serves as an effective buffer during power outages, enabling heavy machinery to maintain functionality without interruption. The ability to ensure continuous operation not only safeguards productivity but also enhances workforce safety, as machinery that ceases unexpectedly can pose significant hazards to operators and surrounding personnel.

2. INTEGRATION OF RENEWABLE ENERGY SOURCES

The electrification of heavy machinery correlates strongly with the growing adoption of renewable energy sources. Solar and wind energy, for instance, have made considerable strides toward becoming mainstays in several industrial sectors. However, the intermittent nature of renewable energy production presents challenges. This is precisely where industrial energy storage shines, as it allows for the capture of excess electricity generated during off-peak production times for later use.

By coupling energy storage systems with renewable electricity generation, industries can create a more resilient energy ecosystem. For instance, during sunny days when solar panel output is at its peak, any surplus energy can be stored in batteries, ready to be deployed at times when energy generation is low, such as during night-time or overcast conditions. This capability not only stabilizes energy supply but also lowers dependence on fossil fuels, contributing to a reduced carbon footprint.

Furthermore, integrating energy storage with renewable energy sources increases energy independence. Industries that can produce and store their energy are less affected by market volatility associated with traditional power sources. This not only allows for better budgeting and forecasting but ultimately leads to increased profitability as operational costs are slashed over time.

3. COST-EFFECTIVENESS AND FINANCIAL IMPACT

The financial implications of transitioning heavy machinery to an electrically powered framework interwoven with industrial energy storage solutions cannot be understated. By facilitating energy cost reductions and enhancing operational efficiency, energy storage systems prove themselves as not just a technical solution, but as a sound investment strategy.

In regions where energy prices fluctuate dramatically based on demand and supply, energy storage can help businesses capitalize on price differentials. During periods of low energy prices, companies can charge their storage systems and draw from them during peak pricing periods. This performance illustrates a direct financial advantage through strategic energy management, allowing industries to minimize their operational costs.

Additionally, with the growing emphasis on sustainability, many governments offer incentives and subsidies for adopting renewable energies and storage systems. By investing in energy storage today, companies can benefit from initial financial support while positioning themselves favorably within a market that increasingly values sustainability. The long-term savings from reduced energy costs, along with potential government benefits, can yield a substantial return on investment.

4. ENHANCING OPERATIONAL EFFICIENCY

Operational efficiency acts as a cornerstone for enhancing productivity within industrial settings, particularly regarding heavy machinery. The introduction of energy storage technologies can significantly alleviate issues related to power interruptions and energy fluctuations, permitting heavy machinery to operate seamlessly.

For industries reliant on heavy machinery, downtime equates to loss — both in production output and financial standing. Utilizing energy storage systems, companies can pre-emptively address power shortages. For example, if an energy storage solution can provide a sufficient power backup during peak operational hours, it empowers industries to operate without interruptions. This not only leads to a more predictable production cycle but also ensures that machinery is always available and ready for use as needed.

Moreover, optimized energy usage through these storage systems contributes to the longevity of machinery. By providing a consistent and stable energy supply, equipment experiences less strain, ultimately promoting a longer life span and reducing maintenance costs—a substantial factor for industries striving to keep their machinery running smoothly and effectively.

FREQUENTLY ASKED QUESTIONS

HOW DOES ENERGY STORAGE IMPACT THE ENVIRONMENT?

Energy storage plays a pivotal role in promoting environmental sustainability by facilitating the use of renewable energy sources. By capturing and storing excess power generated from solar or wind energy, industries reduce their reliance on fossil fuels, leading to fewer greenhouse gas emissions. Additionally, by maximizing the efficiency of energy use and minimizing waste, energy storage helps mitigate environmental impact.

Moreover, energy storage systems serve as a means to ensure stability in power supply, thereby enabling industries to operate with fewer interruptions. The adoption of these technologies aids in transitioning to a greener energy portfolio while demonstrating corporate responsibility.

WHAT TYPES OF ENERGY STORAGE SYSTEMS ARE COMMONLY USED?

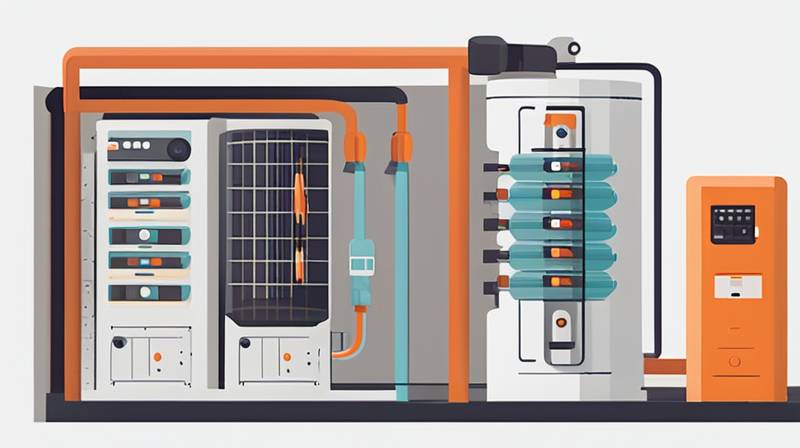

Several energy storage technologies are employed across industrial sectors, with the most prevalent being lithium-ion batteries, lead-acid batteries, and flywheel systems. Lithium-ion batteries are favored for their high energy density and efficiency, making them suitable for a multitude of applications ranging from small devices to large-scale industrial solutions.

Lead-acid batteries, while older technology, are still extensively used due to their reliability and low upfront costs. Flywheel systems, on the other hand, are known for their ability to deliver quick bursts of energy and have minimal maintenance requirements. Each of these systems offers unique benefits and is chosen based on specific operational needs and site conditions.

WHAT ARE THE CHALLENGES IN IMPLEMENTING ENERGY STORAGE SYSTEMS?

While the advantages of energy storage systems are substantial, the implementation of these technologies is not without its obstacles. One prominent challenge is the high upfront capital investment required for installation and development. Companies may demonstrate reluctance to invest without assurance of immediate returns, necessitating a thorough cost-benefit analysis.

Moreover, complexities in integrating these systems with existing infrastructure can present significant hurdles. Industrial facilities must adapt their energy management strategies and ensure compatibility with current machinery, which requires careful planning and evaluation. There is also the challenge of regulatory compliance with local and regional laws concerning energy use and environmental impacts, adding another layer of complexity to energy storage system adoption.

In essence, industrial energy storage facilitates the electrification of heavy machinery by providing a robust and reliable energy source that enhances operational efficiency, promotes sustainability, and economizes energy use. The various facets surrounding this technology initiate a paradigm shift towards more efficient industrial operations, taking advantage of emerging technologies to support heavy machinery powered by renewable sources. Each industrial sector stands to gain substantial benefits from adopting these practices, reducing dependence on fossil fuels and lowering operational costs. As industries navigate the transition toward electrification, the advent of industrial energy storage will determine their adaptability, efficiency, and sustainability long into the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-industrial-energy-storage-support-the-electrification-of-heavy-machinery/