Industrial energy storage serves as a crucial mechanism for addressing fluctuations in energy supply and demand within manufacturing facilities. 1. Energy storage technologies offer enhanced flexibility, 2. They enable improved energy cost management, 3. Industrial energy storage supports sustainability practices, 4. These systems enhance operational reliability. One of the critical aspects of industrial energy storage is its ability to smooth the irregularities associated with renewable energy sources, such as solar and wind power, allowing manufacturers to better match energy consumption with generation. This not only mitigates the effects of peak demand pricing but also can facilitate a transition toward a greener energy landscape, supporting both economic and environmental objectives.

1. THE ROLE OF ENERGY STORAGE IN MANUFACTURING

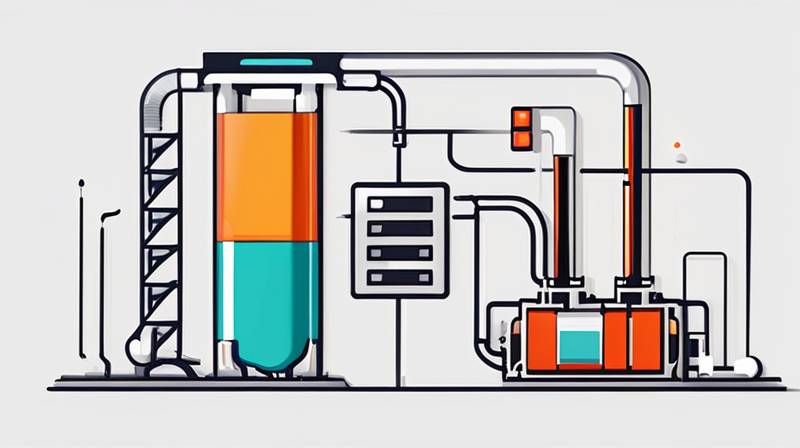

Energy storage systems have become increasingly significant in the context of manufacturing operations. As industries continue to evolve, the demand for a reliable and efficient energy management system has surged. Conventional electricity grids face challenges inherent to supply variability, particularly with the rise of intermittent renewable energy sources. Energy storage systems, such as batteries, flywheels, and pumped hydro storage, provide a viable solution to such challenges. By storing surplus energy during low-demand periods and releasing it during peak periods, these systems afford manufacturers a greater level of control over their energy utilization.

Investing in energy storage technologies allows manufacturing facilities to respond swiftly to fluctuations in energy availability. For instance, battery storage systems enable manufacturers to store electricity generated during off-peak hours, thereby lowering energy costs. This stored energy can then be deployed during peak demand pricing periods, resulting in substantial cost savings. Furthermore, these systems can act as a buffer against grid instability, ensuring that operations remain uninterrupted even in the face of sudden energy supply disruptions. The technological advancements in this sector are progressively enabling manufacturing facilities to implement energy storage as an integral component of their energy strategy.

2. TYPES OF INDUSTRIAL ENERGY STORAGE TECHNOLOGIES

When considering the variety of energy storage systems, the landscape is both diverse and dynamic. Each technology has its unique attributes, advantages, and suitability for specific manufacturing applications. Understanding these options is essential for manufacturers looking to optimize their energy management strategies.

Battery energy storage systems (BESS) are the most commonly recognized solution. They serve various applications, from load shifting to frequency regulation and demand response, which are paramount in adjusting to peaks and troughs in energy supply. Lithium-ion batteries, in particular, have gained traction due to their high energy density, efficiency, and decreased costs over time. Moreover, advancements in battery technology continue to enhance performance, leading to longer life cycles and reduced maintenance costs—critical factors for industrial implementation.

Pumped hydro storage represents a more traditional form of energy storage, employing gravitational potential energy to store and release energy. In this system, excess energy is utilized to pump water up to a reservoir. When demand surges, the stored water is released to generate electricity. This solution, while capital-intensive and location-specific, offers a reliable and mature technology capable of providing substantial energy storage capacity. The efficiencies of pumped hydro systems render them suitable for large-scale energy storage needs, particularly for industries with significant energy consumption fluctuations.

3. BENEFITS OF INDUSTRIAL ENERGY STORAGE

The benefits associated with industrial energy storage systems are manifold. Among these advantages, enhanced operational reliability stands out prominently. By providing a buffer against energy supply variability, storage solutions can sustain manufacturing processes uninterrupted. This reliability is especially crucial for industries where operational downtime leads to significant financial losses, such as pharmaceuticals, food and beverage, and automotive manufacturing sectors.

Another significant benefit of energy storage systems is the cost optimization that comes from load shifting and peak shaving. Manufacturers can leverage stored energy during periods of high energy costs, allowing for better budgeting and reduced operational expenses. As energy prices continue to fluctuate due to a variety of market dynamics, having a robust energy storage solution enables manufacturers to insulate themselves from these unpredictable costs. This financial stability can further enhance their competitiveness in an ever-evolving market landscape.

Moreover, energy storage contributes to sustainability initiatives within manufacturing facilities. Increasingly, regulations and market expectations are compelling manufacturers to adopt greener practices. By integrating renewable energy sources and energy storage systems, facilities can reduce their reliance on fossil fuels and lower their carbon footprints. This transition not only meets regulatory requirements but also appeals to a growing segment of eco-conscious consumers, enhancing brand reputation and loyalty.

4. CHALLENGES OF IMPLEMENTING ENERGY STORAGE SYSTEMS

Despite the numerous advantages offered by energy storage systems, implementing these technologies is not without its challenges. Initial capital investment represents a significant barrier for many manufacturing facilities. While the long-term savings can offset these costs, many companies hesitate to make immediate financial commitments without guaranteed returns.

Additionally, technical complexities associated with the deployment of storage systems can pose challenges. Each energy storage technology has unique operational characteristics, and integrating these systems into existing manufacturing processes necessitates careful planning and execution. Manufacturers must assess their specific needs, facility layout, and energy consumption patterns when selecting an appropriate storage solution.

Another critical challenge pertains to the life cycle management of energy storage systems. While modern battery systems have extended life spans and reduced maintenance requirements, they are not exempt from performance degradation over time. Monitoring and managing the performance and health of these systems is essential to maximizing investment returns, necessitating strategic planning and ongoing evaluation.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COSTS ASSOCIATED WITH INSTALLING ENERGY STORAGE SYSTEMS IN MANUFACTURING FACILITIES?

The costs related to the installation of energy storage systems can be a point of contention for many manufacturers. The initial investment typically encompasses the purchase of the energy storage technology, installation expenses, and potential infrastructure modifications to accommodate the new system. Prices may range widely depending on the type of energy storage technology selected, with lithium-ion batteries often presenting significant capital expenditures upfront. However, manufacturers should consider the long-term economic benefits as well. These savings arise from reduced energy bills due to load shifting and peak shaving, minimizing the environmental impact associated with energy consumption, and providing the opportunity to participate in demand response programs that can offer additional revenue streams.

With the continual improvement in energy storage technologies and the accompanying decreases in capital costs, many energy storage solutions can now pay for themselves within a few years through energy cost savings alone. Some manufacturers may pursue financing options or government incentives to alleviate the burden of upfront costs. Furthermore, detailed analysis of projected energy savings can aid in justifying the investment as part of a broader strategy to enhance operational efficiency.

HOW DOES INDUSTRIAL ENERGY STORAGE CONTRIBUTE TO SUSTAINability IN MANUFACTURING?

Industrially focused energy storage systems play a pivotal role in facilitating sustainability efforts within manufacturing sectors. By integrating renewable energy generation, manufacturing facilities can effectively reduce their reliance on fossil fuels. Energy storage allows surplus energy generated from renewable sources to be stored and utilized when needed, thus ensuring a stable energy supply while minimizing carbon emissions associated with traditional power generation.

Moreover, energy storage systems support the broader electricity grid by decreasing peak demand pressures. During instances of high energy consumption, these systems can discharge stored energy, thereby lessening the burden on fossil fuel power plants that typically ramp up to meet increased demand. This reduction in fossil fuel usage contributes directly to lower greenhouse gas emissions, aligning manufacturing processes with sustainability goals. Additionally, as manufacturing entities move towards adopting circular economy principles, energy storage technologies exemplify the commitment to innovating more sustainable operational practices that encompass energy efficiency and resource conservation.

HOW CAN MANUFACTURERS SELECT THE APPROPRIATE ENERGY STORAGE SYSTEM?

Selecting the most appropriate energy storage system necessitates a thorough evaluation of various factors related to the specific operational context of a manufacturing facility. Critical considerations typically include the anticipated energy consumption patterns, the peak demand requirements, and the extent to which renewable energy generation will be integrated. Manufacturers should conduct a comprehensive energy audit to accurately gauge their energy use, identify peak load periods, and establish energy management objectives.

Another significant factor is the technological compatibility with existing infrastructure. When introducing a new energy storage system, it’s essential to ensure that it can effortlessly integrate with current manufacturing systems and technologies. Additionally, manufacturers must also consider the total cost of ownership that includes installation, operational, and maintenance expenses over the system’s life cycle. Seeking expert consultation from energy management professionals can further inform the decision-making process and help manufacturers identify the best possible energy management strategy tailored to their unique needs.

Industrial energy storage is becoming increasingly integral in the quest for a more efficient and sustainable manufacturing ecosystem. The forward momentum toward cleaner technologies and innovative energy management is reshaping the industrial landscape, rendering it imperative for manufacturers to explore the potential associated with energy storage solutions. Such systems enhance operational efficiency, optimize energy costs, and contribute to overarching sustainability initiatives.

The integration of energy storage does not merely present a financial advantage; it signifies a substantial shift toward a future where manufacturing can harmonize operations with environmental responsibility. By leveraging advanced energy storage technologies, manufacturers can create a more resilient infrastructure capable of withstanding the vicissitudes of energy volatility. This resilience is foundational for thriving in an energy-constrained world. Furthermore, in an era characterized by growing awareness around sustainable practices, the integration of energy storage can serve as a powerful differentiator for manufacturers aiming to bolster their reputational capital while aligning with environmental regulations.

Ultimately, the deployment of industrial energy storage systems empowers manufacturers to adapt to shifting energy paradigms while realizing substantial economic, operational, and environmental benefits. As energy systems continue to evolve, the role of energy storage will undoubtedly expand, solidifying its relevance and importance in the manufacturing sector. In this context, manufacturers must embrace the strategic advantages presented by energy storage, positioning themselves favorably amid emerging challenges and opportunities.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-industrial-energy-storage-help-manage-energy-volatility-in-manufacturing-plants/