Dynamic cooling control logic differs from conventional thermal management systems primarily in its real-time adaptability and optimization capabilities.

Conventional Thermal Management Systems:

- Typically rely on fixed setpoints and predefined responses based on temperature thresholds.

- Use controllers such as PID (Proportional, Integral, Derivative) that continuously monitor the temperature and adjust cooling output accordingly to maintain a stable setpoint. The control is reactive, based on the current and past temperature errors, and sometimes predicted future trends, to stabilize temperature (e.g., by controlling fans or compressors).

- Cooling is generally managed in a somewhat static manner, reacting to temperature changes by turning cooling devices on/off or adjusting them proportionally, without extensive consideration of system-wide efficiency or dynamic interdependencies.

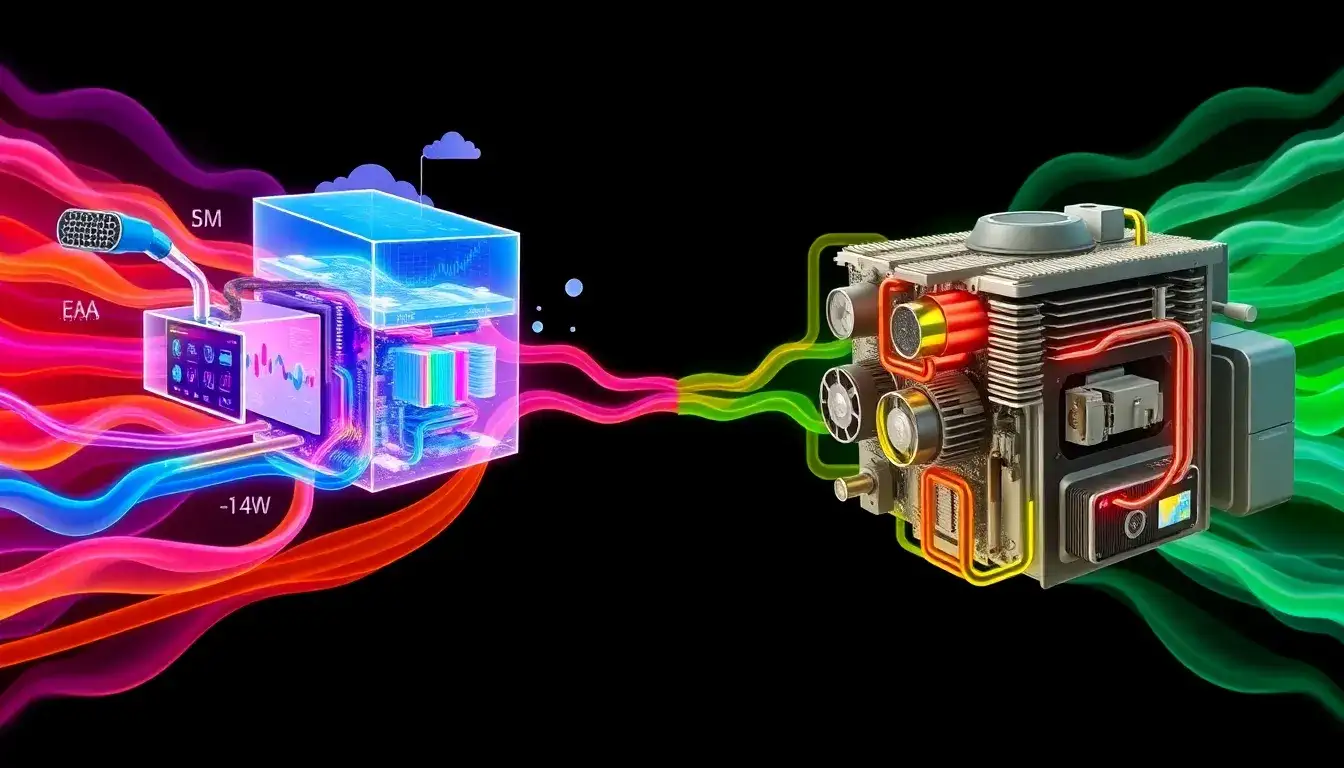

Dynamic Cooling Control Logic:

- Involves real-time monitoring across multiple components or systems and applies dynamic optimization techniques to enhance overall cooling efficiency.

- Uses advanced algorithms and control strategies that adjust cooling parameters continuously based on real-time data and possibly predictive models to optimize energy use, cooling performance, and system reliability simultaneously.

- Rather than simply maintaining a temperature setpoint, dynamic cooling actively optimizes the cooling operation to reduce energy consumption and improve effectiveness, adjusting to varying loads, environmental conditions, and system interactions on the fly.

- This approach can incorporate sophisticated logic implemented in simulation and modeling languages (such as Modelica) for advanced control, enabling smarter decision-making in thermal applications.

Summary Table:

| Feature | Conventional Thermal Management | Dynamic Cooling Control Logic |

|---|---|---|

| Control style | Fixed setpoints, mostly reactive (PID) | Real-time, adaptive, predictive, and optimized |

| Optimization focus | Maintain temperature setpoint | Maximize energy efficiency and cooling effectiveness |

| Monitoring | Single or limited sensors, simple feedback | Extensive sensor data, system-wide real-time data |

| Algorithm complexity | Simple PID or heuristic control | Advanced control algorithms, model-based optimization |

| Response | Reacts to temperature deviations | Continuously adjusts cooling dynamically |

In essence, dynamic cooling control logic enhances conventional thermal management by integrating real-time data and advanced control algorithms to optimize cooling performance and energy use dynamically rather than following fixed reactive schemes.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-dynamic-cooling-control-logic-differ-from-conventional-thermal-management-systems/