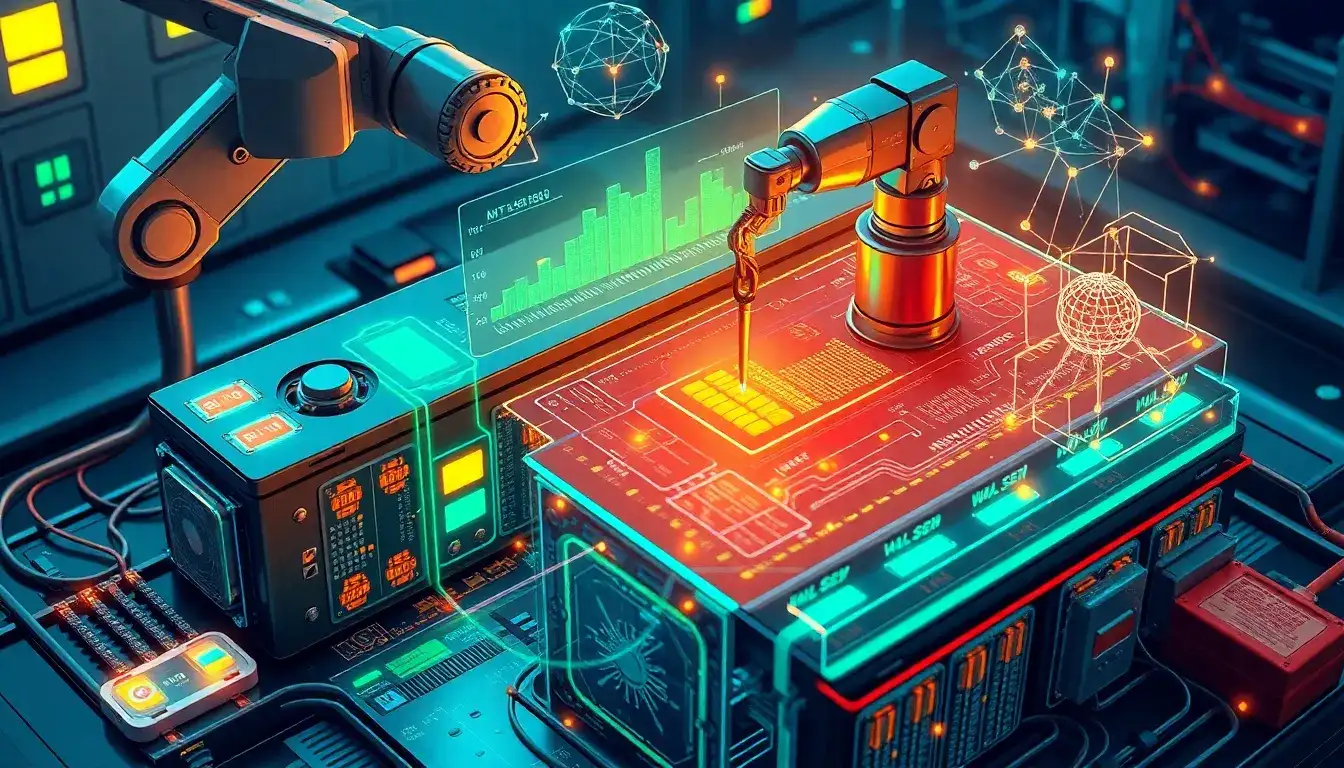

AI-driven predictive maintenance in battery systems works by continuously monitoring and analyzing battery data through advanced algorithms and machine learning techniques to forecast potential failures and optimize battery performance and lifespan.

How AI-driven Predictive Maintenance Works in Battery Systems

- Data Collection: The battery management system (BMS) gathers real-time data from various sensors, including measurements of temperature, voltage, current, and key battery health indicators such as State of Charge (SoC) and State of Health (SoH).

- Data Analysis and Modeling: AI and machine learning models process this data to detect patterns and anomalies indicative of battery degradation or impending faults. These models are trained on large datasets that enable them to predict future battery behavior with high accuracy—up to 10 times more precise than traditional industrial standards.

- Predictive Insights: The system predicts when maintenance should be performed before failure occurs, enabling a shift from reactive or scheduled maintenance to a proactive approach. This reduces unexpected downtime, prevents thermal events, and optimizes battery usage to extend its operational life.

- Maintenance Optimization: By identifying the optimal timing for maintenance or troubleshooting, AI-driven systems help reduce costs associated with unnecessary or emergency repairs. Reported savings from predictive maintenance range from 30-40% compared to reactive and 8-12% compared to preventive maintenance.

- Safety and Reliability Improvement: Early detection of issues such as overheating or capacity loss enhances battery safety and reliability, which is critical for applications like electric vehicles and large-scale energy storage systems.

Example Application

Tesla’s Battery Management System exemplifies AI-driven predictive maintenance by using an intricate sensor network and data analytics to continually monitor battery parameters, enabling early detection of deviations and proactive interventions to maintain optimal battery health.

In summary, AI-driven predictive maintenance in battery systems leverages real-time data, machine learning, and predictive algorithms to forecast battery health and failures ahead of time, thereby improving performance, safety, and cost-efficiency in battery operation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-ai-driven-predictive-maintenance-work-in-battery-systems/