The mining and refining processes of electric vehicle (EV) battery materials significantly impact their carbon footprint due to several factors:

Impact on Carbon Footprint

- Energy Consumption and Emissions:

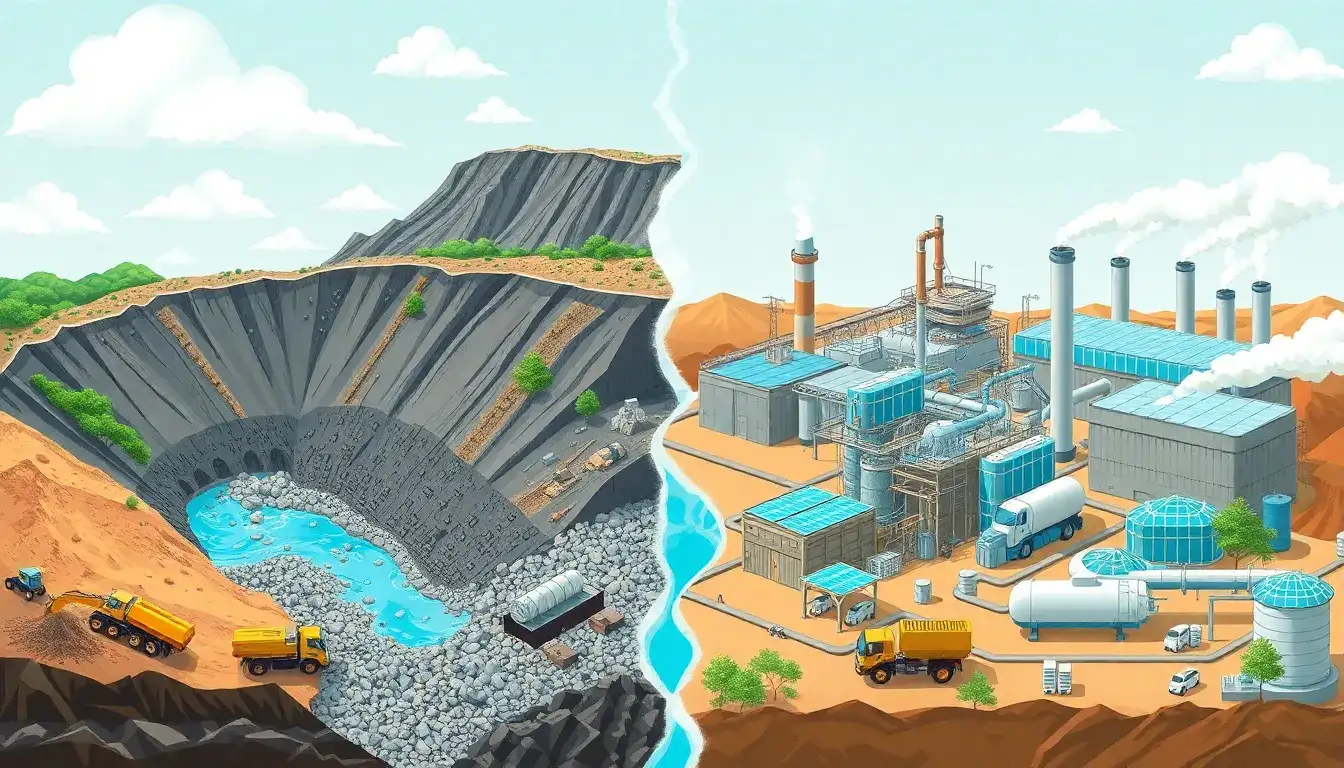

- Mining and Refining: The extraction, processing, and refining of raw materials like lithium, cobalt, nickel, manganese, and graphite require substantial amounts of energy. This process is often energy-intensive and can lead to significant greenhouse gas emissions if fossil fuels are used.

- Production Emissions:

- On average, mining and refining raw materials account for about 25% of total battery production emissions. For instance, producing a typical EV with a 75-kWh battery pack emits more than seven tons of CO₂e emissions from the battery alone.

- Process Specifics:

- Hydrometallurgy vs. Pyrometallurgy: The choice between hydrometallurgical and pyrometallurgical methods depends on the minerals and can influence energy use and emissions. Pyrometallurgical processes often involve high temperatures and thus higher energy consumption.

- Renewable Energy Usage:

- The carbon footprint can be reduced if renewable energy sources like solar or wind power are used instead of fossil fuels during the production process.

- Material Selection and Chemistry:

- The battery chemistry and the selection of raw materials can affect emissions. Some mineral combinations are more environmentally friendly than others, and sourcing decisions can significantly impact the footprint.

Environmental Considerations

- Environmental Tolls: The mining process for critical battery minerals often comes with both environmental and human costs, particularly in regions like the Democratic Republic of Congo for cobalt.

Despite these challenges, there are efforts to decarbonize the production process and improve sustainability in the EV battery supply chain. Additionally, there are more than enough mineral resources globally to support a transition to electric vehicles, which suggests potential for growth in sustainable mining practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-the-mining-and-refining-processes-of-ev-battery-materials-impact-their-carbon-footprint/