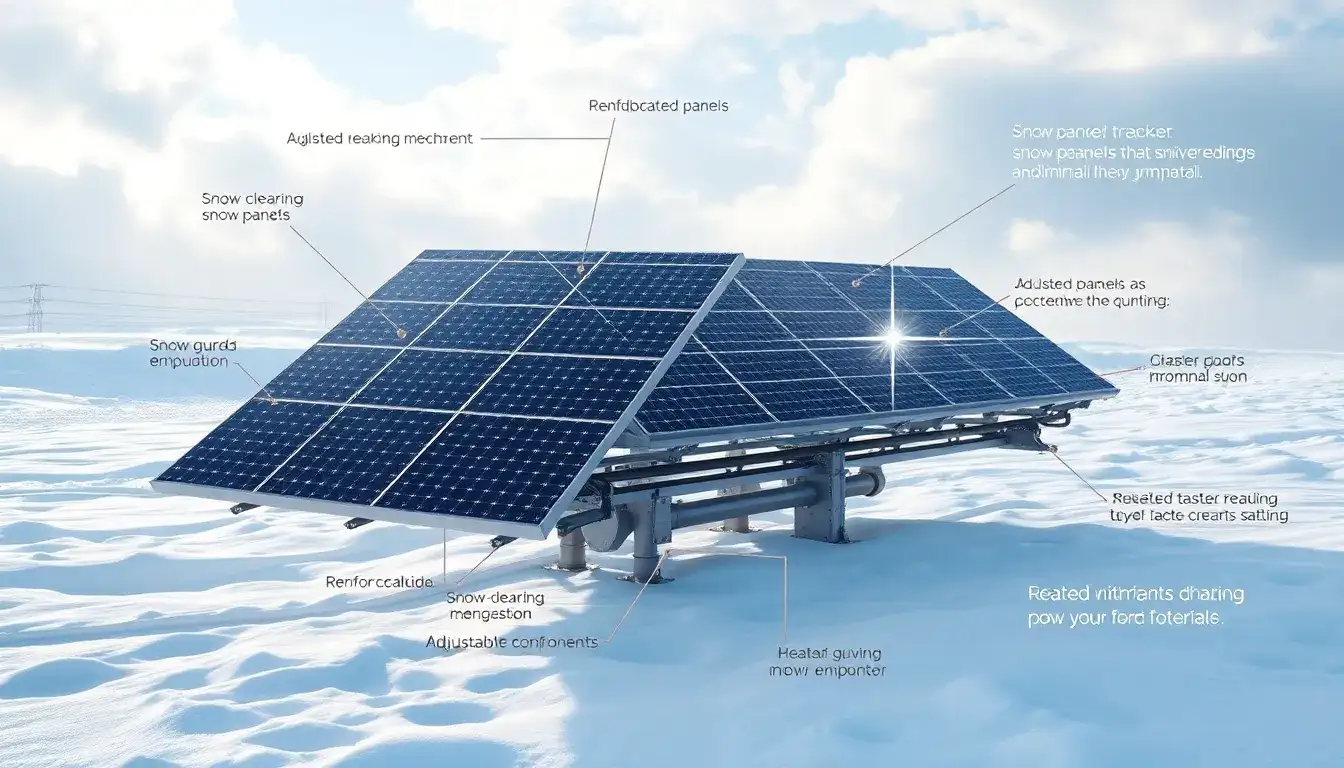

Solar trackers manage heavy snowfall through a combination of mechanical design adaptations, sensor-driven automated responses, and operational strategies aimed at shedding snow and protecting the system from excessive snow loads.

Key Methods Solar Trackers Use to Handle Heavy Snowfall

1. Tilting Panels to Shed Snow

A common and primary solution is to tilt the solar panels to a steep angle, often positioning the rows down to one side, so snow can slide off more easily, preventing excessive buildup on the modules. This is often done automatically when snow is detected to reduce the weight load and shading effects of snow coverage.

2. Use of Snow Sensors and Automated Control Systems

Advanced solar tracker systems equip snow sensors that measure the amount of snow accumulating on the panels. When snow reaches a certain threshold, the tracker control system automatically tilts the panels to the maximum tilt position to optimize snow shedding. This prevents unnecessary movements when snow levels are low and protects the structural integrity of the tracker by avoiding excess snow loads.

3. Structural Design Considerations

Solar trackers designed for snowy regions account for the static and dynamic loads of snow accumulation. The trackers are built to withstand the weight of snow resting on the modules and to operate safely even under these loads. Internal relief valves or overcurrent protections prevent the tracker gear from damaging itself by stopping or reversing motion if snow or ice obstructs movement.

4. Managing Snow Drift and Freeze-Thaw Effects

Snow can drift and pile up beneath panel rows, especially in windy conditions, which can reduce clearance beneath the tracker and cause mechanical issues or damage. Freeze-thaw cycles can harden the snow pack, increasing the risk of damage. Advanced trackers use atmospheric sensors and safety algorithms to predict and react to these conditions, adjusting panel positions to minimize risks from heavy or hardened snow.

5. Stow Positions for Snow and Extreme Weather

When snow sensors detect accumulation, trackers move to a “snow stow” position where the tilt is maximized to facilitate snow slide-off and reduce snow load on the panels. This is an automated strategy that ensures panels are positioned optimally for both snow shedding and protection of the mechanical system. This stow strategy also facilitates quicker recovery after snow clearance, restoring panels to normal operational angles without manual intervention.

Summary Table of Snow Handling Features in Solar Trackers

| Feature | Description |

|---|---|

| Panel tilting for snow shed | Panels tilt to steep angles to allow snow to slide off |

| Snow sensors | Detect snow accumulation and trigger tilt adjustments |

| Automated snow stow | Trackers move automatically to a maximum tilt position when snow is detected |

| Structural overload protection | Relief valves and overcurrent protections prevent damage from snow or ice obstruction |

| Sensor-driven adaptive response | Atmospheric sensors and algorithms adjust to snow, wind, and freeze-thaw conditions |

| Management of snow drift | Adjust clearance to prevent damage from piled snow under panels |

These measures collectively ensure solar trackers remain operational and safe during heavy snowfall, minimizing energy loss due to snow cover and protecting the mechanical components from damage. Modern tracker systems integrate these features into real-time control systems to respond dynamically to winter weather challenges, thus maintaining energy production and reducing maintenance costs.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-solar-trackers-handle-heavy-snowfall/