Manufacturing and logistics improvements significantly contribute to lowering battery costs by enhancing efficiency, reducing waste, and optimizing supply chains. Here are some key ways these improvements impact battery costs:

Manufacturing Improvements

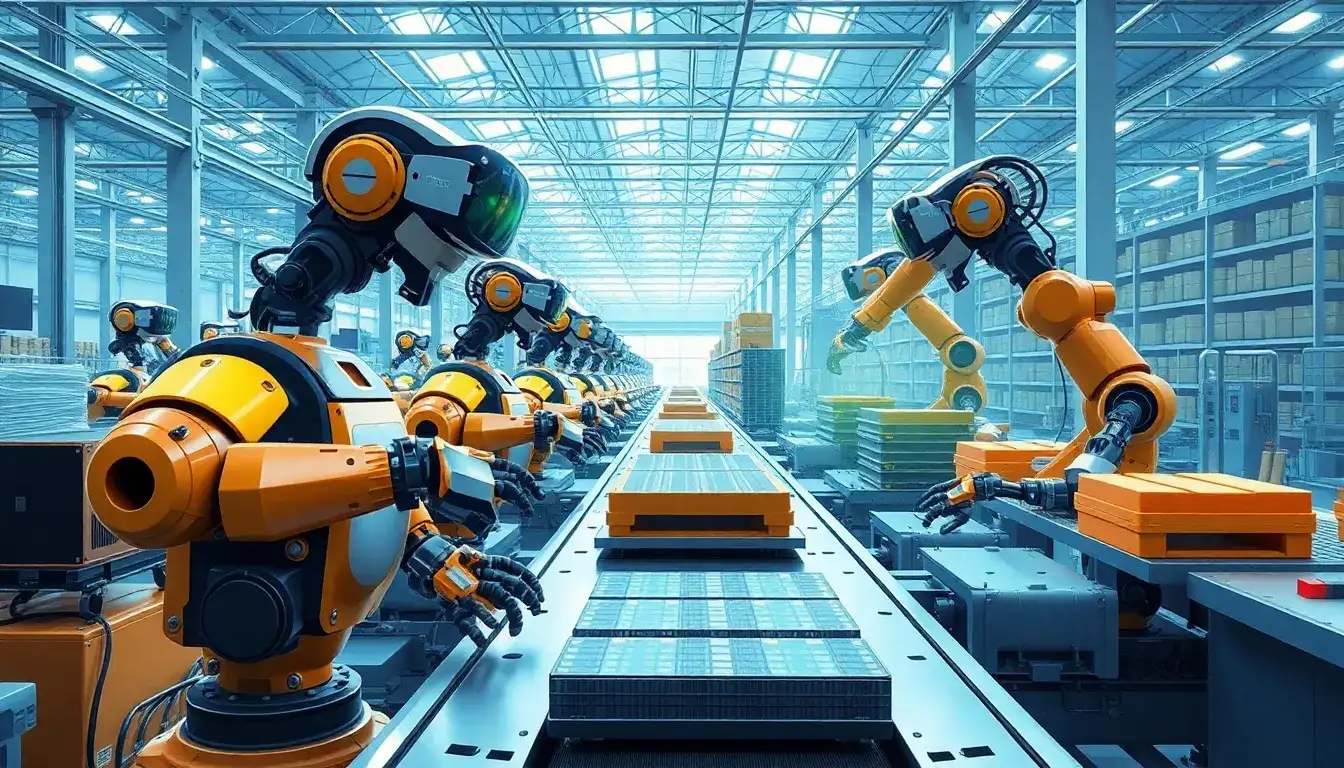

- Automation and AI: The use of automation and artificial intelligence (AI) in battery manufacturing helps eliminate errors, speed up production, and optimize resource usage. This not only reduces operating costs but also allows for real-time monitoring and quick defect identification, leading to better product quality and fewer complaints.

- Lean Manufacturing: Implementing lean manufacturing techniques streamlines production processes, reducing unnecessary labor expenses and waste. This approach can lead to significant cost savings by making each step in the production process more efficient.

- Economies of Scale: Building large-scale manufacturing facilities, such as gigafactories, enables producers to spread fixed costs over a larger number of units. This approach also allows for better negotiation of raw material prices and reduced transport costs due to localized supply chains.

Logistics Improvements

- Supply Chain Efficiency: Strengthening regional supply chains by locating production near raw material suppliers and manufacturers reduces transportation costs and risks associated with international trade disruptions. This proximity also increases supply chain responsiveness to market changes.

- Advanced Logistics Technologies: The use of digital tools like predictive analytics and supply chain management software helps manage inventory more effectively, reducing overproduction and stock shortages. Improved logistics planning decreases shipping costs and ensures timely delivery.

- Vertical Integration: Companies like BYD have achieved cost advantages through vertical integration, allowing them to source materials at lower costs by controlling their supply chain more effectively.

By combining these strategies, manufacturers can significantly lower battery production costs while improving the efficiency and resilience of their operations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-manufacturing-and-logistics-improvements-contribute-to-lower-battery-costs/