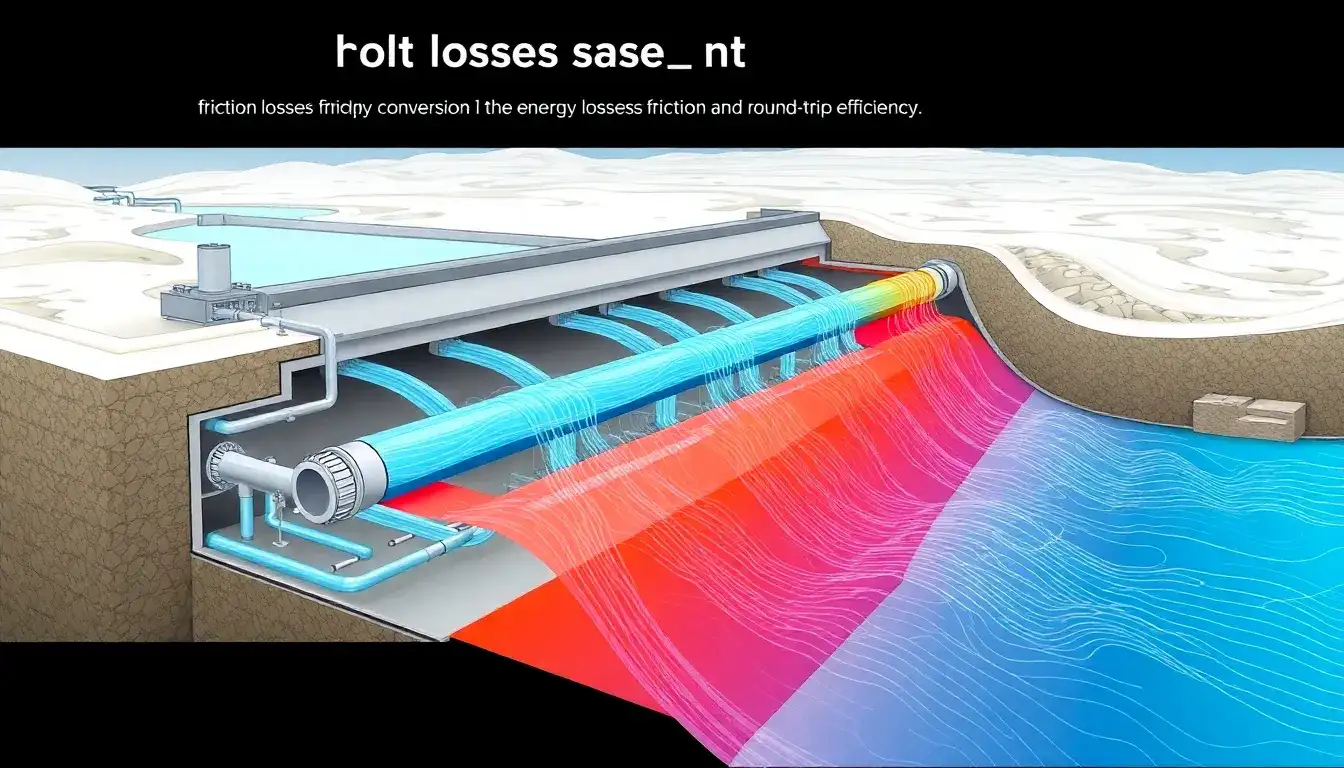

Friction losses in pipes significantly impact the round-trip efficiency of pumped hydroelectric plants (PHES) by increasing energy dissipation during both pumping and generation cycles. When water is pumped uphill, frictional losses convert electrical energy into waste heat instead of potential energy. During power generation, these same losses reduce the kinetic energy of water before it reaches turbines. Key factors include:

1. Energy dissipation mechanics

Friction converts mechanical energy into heat through viscous effects and turbulence, particularly in long penstocks or complex piping networks. This directly reduces the net energy available for storage or generation.

2. Viscosity and turbulence effects

Higher water viscosity (temperature-dependent) and turbulent flow regimes increase friction losses. Rough pipe surfaces and fittings (valves, bends) exacerbate turbulence, further elevating energy loss.

3. System design implications

- Pumping phase: Friction increases power demand for a given flow rate, reducing stored potential energy per unit of input electricity.

- Generation phase: Reduced water pressure at turbines lowers electricity output.

4. Round-trip efficiency impact

Typical PHES systems achieve 70-85% round-trip efficiency under optimal conditions. Friction losses in piping systems are a primary contributor to the remaining 15-30% energy loss, alongside other factors like generator inefficiencies. Mitigation strategies (smooth pipes, optimized routing) directly improve this metric by reducing hydraulic resistance.

The relationship follows:

ηround-trip ∝ &frac1{frictional head loss}

where higher friction lowers overall efficiency.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-friction-losses-in-pipes-affect-the-round-trip-efficiency-of-pumped-hydroelectric-plants/