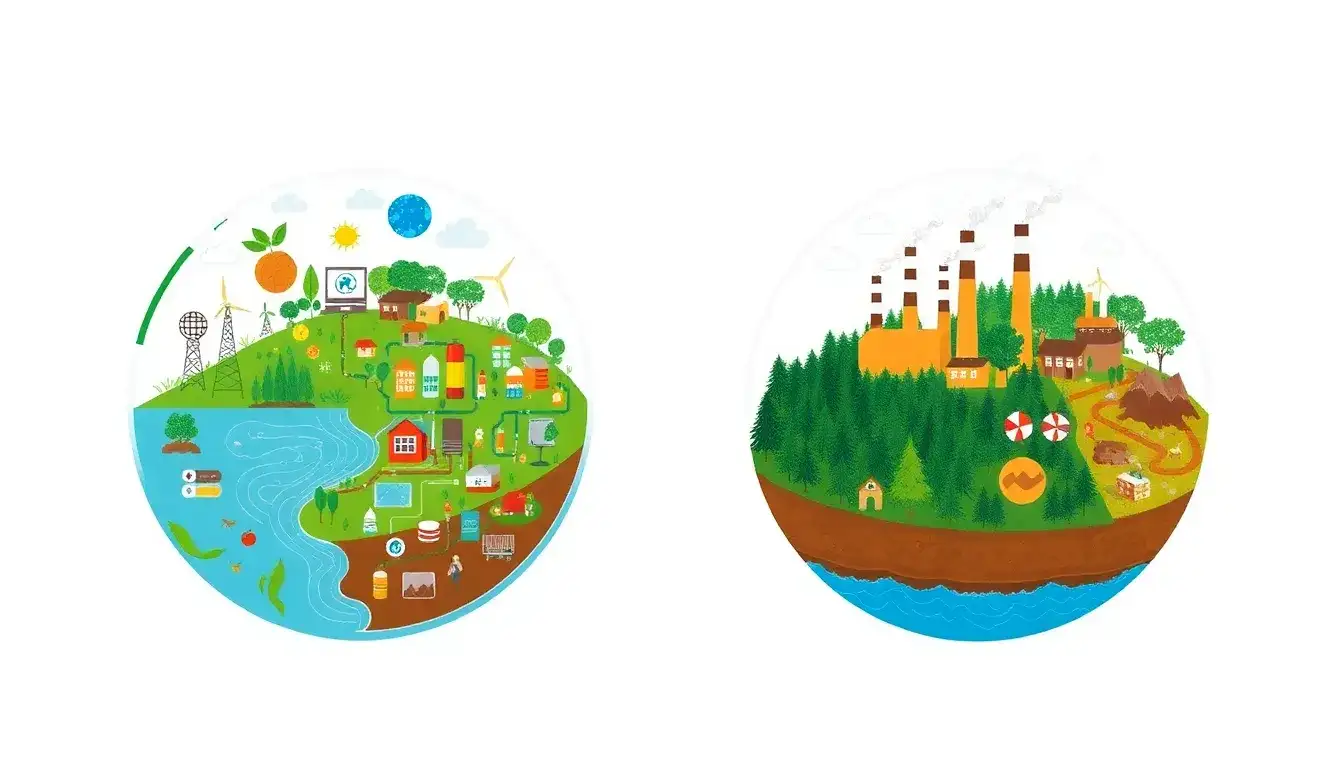

Closed-loop systems reduce environmental impacts compared to open-loop systems primarily by promoting waste minimization, resource efficiency, and lower emissions through recycling and reuse within production processes. Here are the key ways closed-loop systems achieve this:

Waste Reduction and Resource Efficiency

- Closed-loop systems recycle or reuse materials internally instead of discarding waste, significantly reducing the amount sent to landfills or released into the environment. This keeps waste out of landfills and reduces the need for virgin raw materials.

- By reprocessing materials such as plastics or nylon fibers, closed-loop manufacturing extends the lifecycle of resources, decreasing the frequency of producing new products and minimizing the overall environmental footprint associated with extraction, processing, and disposal.

Energy Consumption and Emissions

- Closed-loop systems typically consume less energy than traditional linear (open-loop) systems due to reduced primary resource extraction and the use of less energy-intensive recycling and remanufacturing methods.

- Lower energy use directly translates to reduced greenhouse gas emissions, contributing to climate change mitigation.

- Optimized logistics in closed-loop supply chains decrease emissions from transportation activities by integrating reverse logistics efficiently.

Conservation of Natural Habitats and Biodiversity

- Closed-loop systems reduce the need for land clearing and resource exploitation, helping preserve natural habitats and biodiversity.

- This results in less deforestation, land degradation, and habitat destruction, easing pressure on ecosystems.

Summary Table

| Environmental Impact Aspect | Closed-Loop Systems | Open-Loop Systems |

|---|---|---|

| Waste generation | Minimized by recycling and reuse | High waste generation, often discarded |

| Resource usage | Reduced virgin material demand | High demand for virgin resources |

| Energy consumption | Lower due to recycling and efficient processes | Higher due to raw material extraction |

| Greenhouse gas emissions | Reduced emissions from energy and transport | Higher emissions from production and waste |

| Land use and habitat impact | Smaller footprint preserving natural habitats | Larger footprint causing habitat loss |

| Product lifecycle | Extended by remanufacturing and refurbishment | Shorter product lifecycles, more frequent remanufacture |

In essence, closed-loop systems embody circular economy principles that cyclically reuse materials, thereby minimizing environmental harm compared to the linear “take-make-dispose” nature of open-loop systems. They reduce waste, conserve resources, cut energy use, lower emissions, and protect ecosystems, making them critical for sustainable industrial and manufacturing practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-closed-loop-systems-reduce-environmental-impacts-compared-to-open-loop-systems/