Compressed-air energy storage (CAES) systems manage the heat generated during the air compression process through different strategies, which significantly affect their overall efficiency and operation mode. When air is compressed, it heats up; managing this heat is critical for performance and energy recovery. Here are the main methods and approaches CAES systems use to handle that thermal energy:

Heat Management Approaches in CAES

1. Adiabatic CAES

– In adiabatic systems, the heat generated during compression is captured and stored rather than being wasted. This stored thermal energy is then reused to reheat the compressed air during expansion, improving energy efficiency.

– The heat can be stored in various media such as solids (concrete, stone), fluids (hot oil up to 300 °C), molten salts (up to 600 °C), or even hot water.

– This approach aims for near 100% theoretical efficiency (round-trip efficiency is practically around 70%).

– Advanced adiabatic systems integrate high-efficiency thermal energy storage units like packed bed thermal storage to retain and reuse compression heat, boosting performance beyond traditional methods.

2. Diabatic CAES

– Traditional diabatic CAES dissipates much of the compression heat into the atmosphere using intercoolers during the compression phase.

– Because this heat is lost, the air must be reheated by burning fuel or another external source prior to expansion, which lowers overall efficiency and increases operational costs and emissions.

– Diabatic systems typically do not recover the compression heat but rely on fuel input during expansion to generate energy.

3. Isothermal and Near-Isothermal CAES

– These designs aim to keep the air temperature nearly constant during compression by rapid heat exchange with the environment, minimizing temperature changes and energy losses.

– This approach requires sophisticated cooling during compression but can reduce the need for large thermal storage systems. It is less common at large scale compared to adiabatic and diabatic methods.

Practical Heat Recovery and Storage Techniques

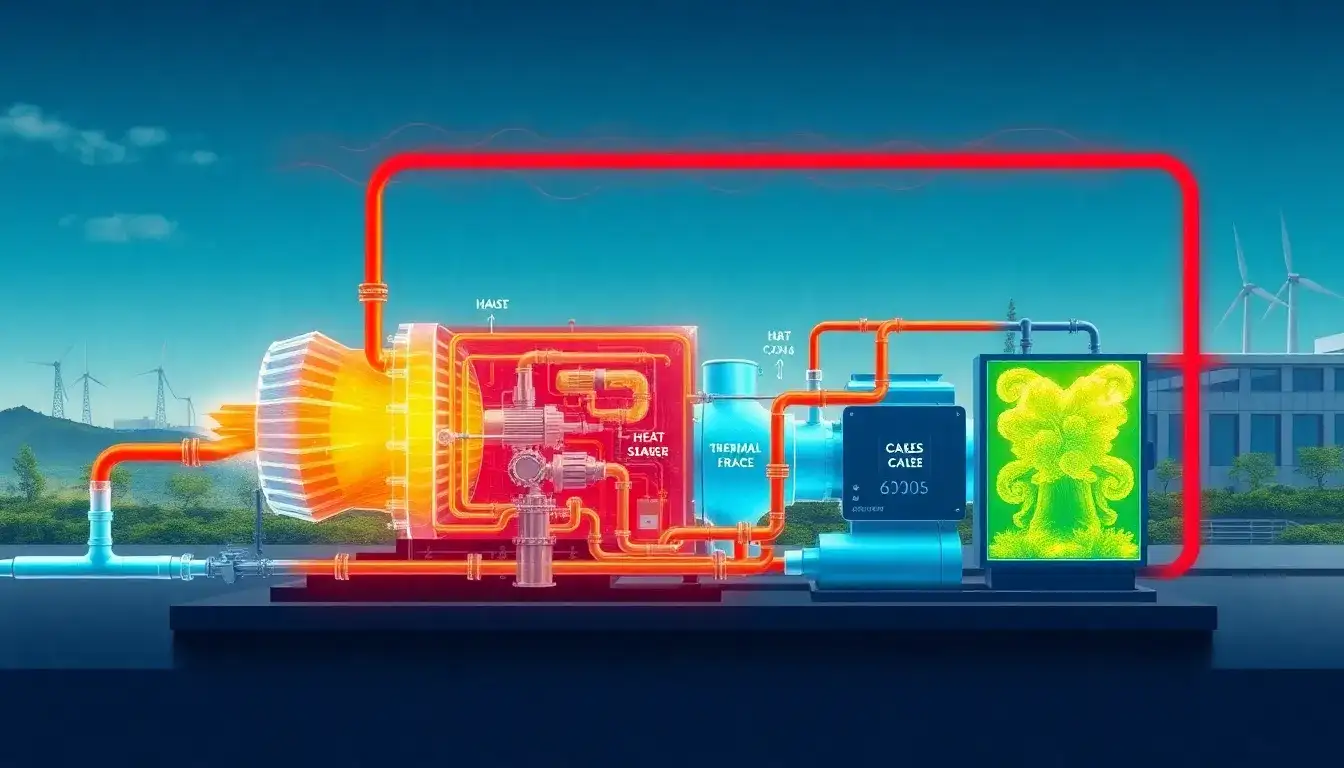

- Heat exchangers and air coolers extract heat from compressed air between compressor stages. Part of this heat is stored in thermal energy storage (TES) units, while some heat is lost to ambient air.

- Examples include thermal storage tanks and packed bed units that temporarily hold the heat at high temperature for later reuse during air expansion in turbines.

- Approximately 17% of compression energy can be lost through air coolers, and about 7% dissipated into ambient air during discharge. Efficient TES design aims to reduce these losses and improve reuse of compression heat.

Summary Table of CAES Heat Management

| CAES Type | Heat Handling Approach | Heat Storage Mediums | Efficiency Impact |

|---|---|---|---|

| Adiabatic | Captures and stores heat | Concrete, stone, hot oil, molten salt | Round-trip efficiency ~70%+ |

| Diabatic | Dumps heat to the atmosphere | No thermal storage, reheated by fuel | Lower efficiency, fuel dependent |

| Isothermal | Maintains near-constant T | Rapid heat exchange with environment | Minimizes losses, complex design |

In essence, effective management of heat in CAES involves either capturing and storing the compression heat to reuse during expansion (adiabatic), losing the heat and compensating by external reheating (diabatic), or controlling temperature during compression to minimize heat generation (isothermal). The adiabatic method with thermal energy storage is the most promising for improving CAES efficiency and sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-do-caes-systems-manage-the-heat-generated-during-the-compression-process/