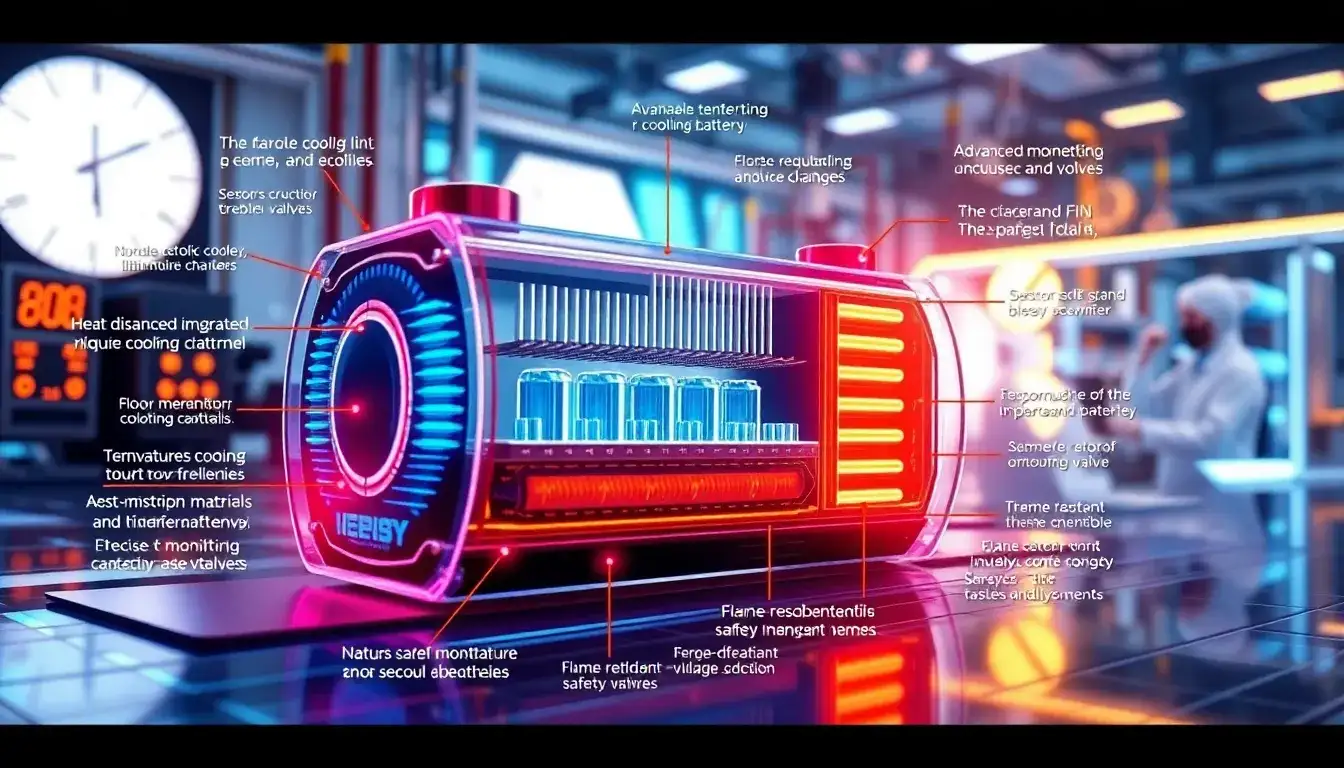

Thermal runaway in lithium-ion batteries can be prevented through a combination of proper storage, advanced battery management, design improvements, and safety measures. Key prevention methods include:

Proper Storage and Temperature Control

- Store batteries within an ideal temperature range generally between about 40°F to 90°F (5°C to 32°C), though exact ranges vary by battery type and manufacturer. Avoiding high temperatures reduces internal chemical reactions that can trigger thermal runaway.

Battery Management Systems (BMS)

- Use specialized battery management systems designed for lithium-ion chemistry that continuously monitor data at the cell level, including voltage, current, temperature, and impedance.

- BMS can detect signs of abnormal temperature rise or other conditions that precede thermal runaway and take protective actions such as disconnecting the battery from the circuit to stop current flow.

Design and Material Improvements

- Employ robust separators within cells that resist short circuits between the anode and cathode even at elevated temperatures.

- Incorporate thermal insulation materials, like intumescent polymers, between cells to prevent heat transfer and propagation of thermal runaway from one cell or module to adjacent ones.

- Use thermal barriers designed to absorb or dissipate heat effectively, helping to isolate affected cells and contain thermal events within battery packs.

Physical Configuration

- Design battery packs with physical spacing or isolation features that allow for better heat dissipation and reduce the risk of cascading thermal runaway between cells or modules.

Quality Control and Maintenance

- Implement stringent manufacturing quality control to detect defects such as metallic contaminants or electrode misalignments that increase the risk of internal short circuits.

- For battery types like VRLA, conduct regular maintenance and inspections to monitor critical parameters, further reducing risks.

By combining these approaches—careful temperature management, cell-level monitoring through BMS, robust battery design with thermal barriers and separators, physical separation of cells, and rigorous quality control—the risk of thermal runaway in lithium-ion batteries can be effectively minimized, improving safety and battery longevity.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-can-thermal-runaway-in-lithium-ion-batteries-be-prevented/