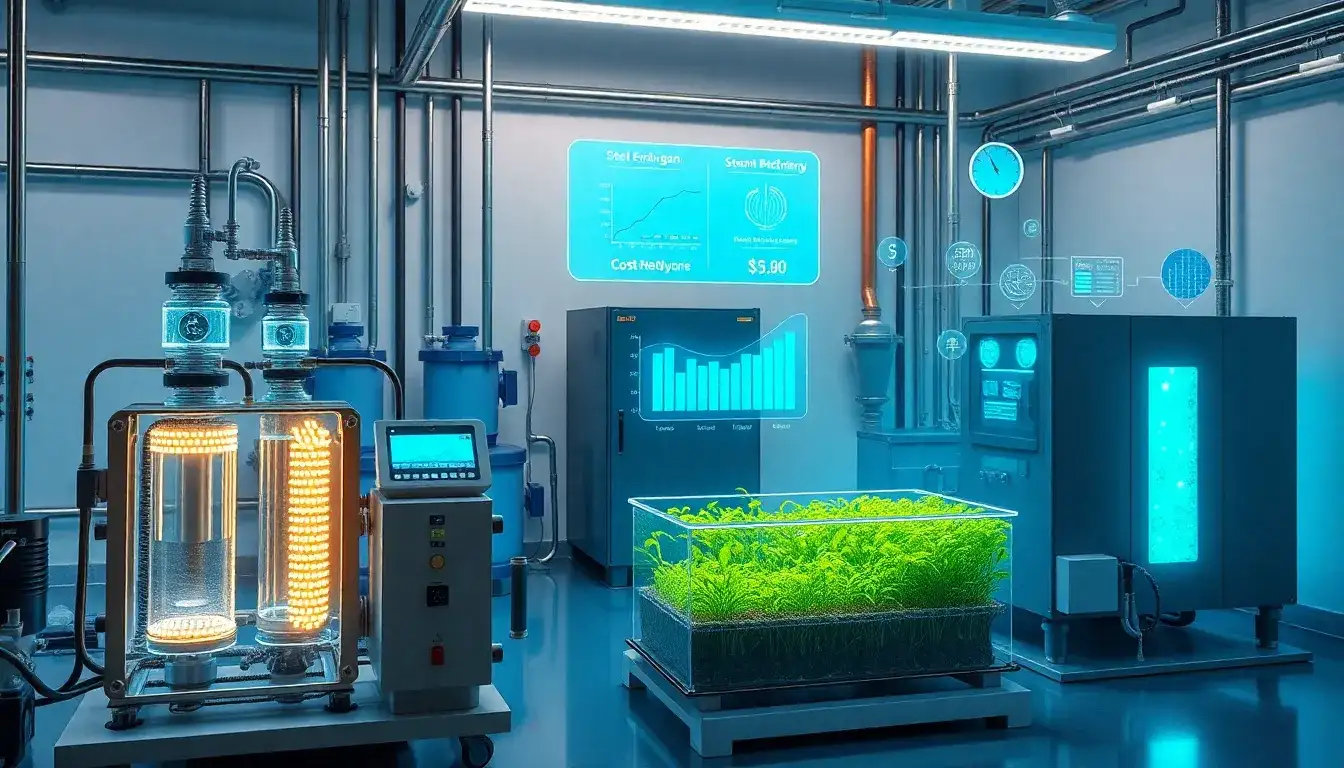

Key Strategies to Reduce Hydrogen Production Costs

1. Scale Up Production Facilities

Increasing the size of hydrogen production plants significantly lowers costs. For example, scaling from 1 MW plants (typical today) to 20 MW plants can reduce production costs by over one-third by improving efficiency and spreading capital costs over more output.

2. Improve Electrolyser Technology and Manufacturing

– Electrolyser cost is a major component of green hydrogen production. Reducing electrolyser capital costs by 40% in the short term and up to 80% in the long term is possible through design innovation and mass manufacturing.

– Increasing stack production volumes, especially to gigawatt-scale automated manufacturing, can almost halve stack costs. For PEM electrolysers, producing around 1,000 units annually can reduce stack costs by nearly 50%.

– Standardizing system components and optimizing plant design contributes to cost savings beyond the electrolyser stack itself.

3. Improve System Efficiency and Flexibility

Optimizing system design to maximize efficiency and flexibility depending on application needs helps reduce overall costs by improving energy use and operational performance.

4. Reduce Cost of Supporting Technologies

– Innovations in filtration and other ancillary technologies can help reduce costs in green hydrogen production projects.

– In the hydrogen fuel distribution chain, reducing costs of compressors, dispensers, and refueling stations through volume scaling and technology innovation (e.g., lower pressure fueling) can cut costs significantly and improve reliability.

5. Increase Investment and Coordination

Cost reductions require coordinated investment across the entire hydrogen value chain, including production, distribution, and refueling infrastructure. Collaboration among governments, industry, research labs, and startups supports standardization and commercialization of the most cost-effective technologies.

6. Use Cheaper Renewable Electricity

Since electricity cost dominates hydrogen production expense, accessing cheaper renewable energy directly lowers hydrogen costs. Long-term projections show up to 85% cost reduction from combined lower electricity prices and electrolyser improvements.

By combining larger-scale plants, improved electrolyser manufacturing, system design optimization, advancements in peripheral technologies, and coordination across the value chain, the cost of hydrogen—especially green hydrogen—can be substantially reduced, making it competitive and scalable for widespread use in sectors like heavy-duty transportation and industry.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-can-the-cost-of-hydrogen-production-be-reduced/