Reducing manufacturing costs for solid-state batteries involves several strategies:

Key Strategies for Cost Reduction

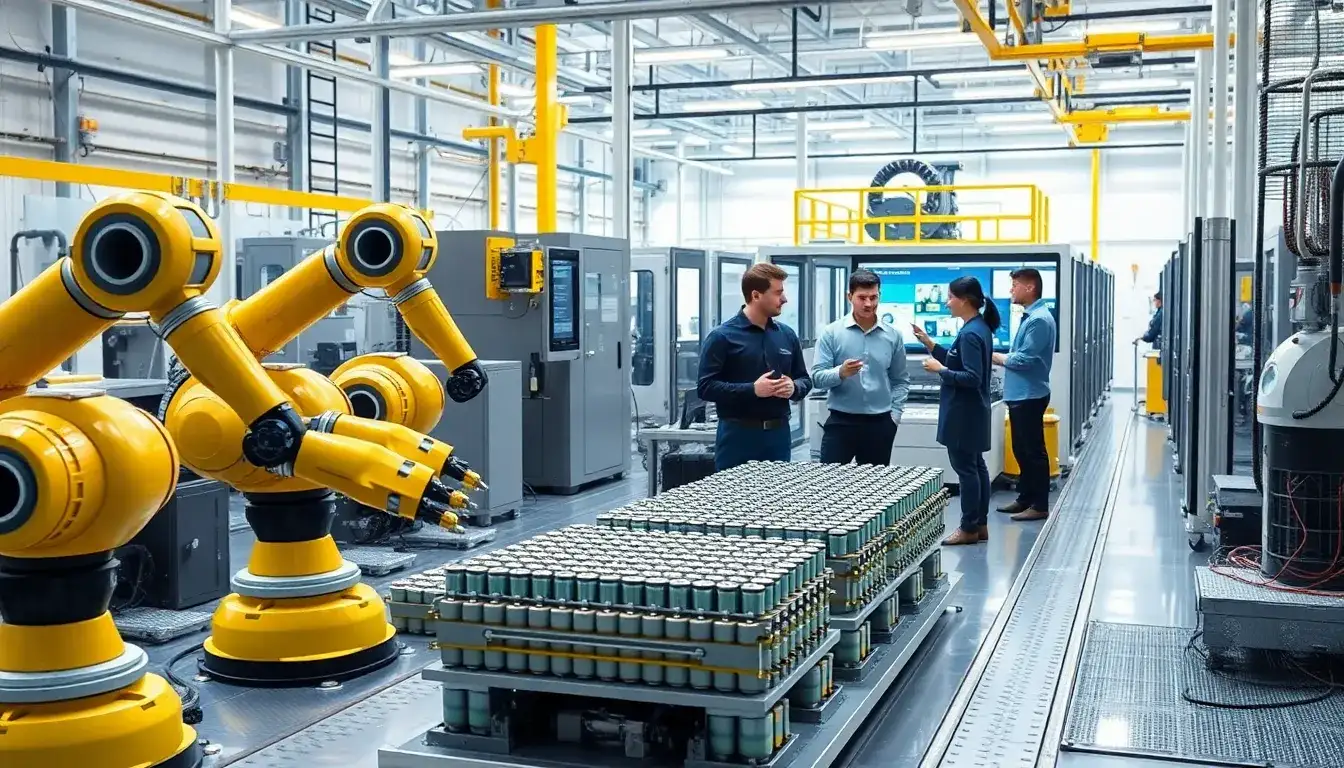

- Scaling Production:

- Increased Volume: As production scales up, economies of scale can help reduce costs. Major manufacturers like Toyota, Nissan, and Samsung SDI have begun pilot production to increase volume and reduce costs over time.

- Predicted Price Drop: By 2030, production costs are expected to drop to $75-100 per kWh, making solid-state batteries more competitive.

- Efficient Manufacturing Processes:

- Roll-to-Roll Processing: Implementing techniques like roll-to-roll processing can improve efficiency, reduce energy consumption by about 50%, and enhance manufacturing speed by 20-50%, contributing to cost savings.

- Simplification of Components: Solid-state batteries combine the separator and electrolyte into one component, potentially reducing material and manufacturing costs.

- Supply Chain Optimization:

- Developing a mature supply chain is crucial for reducing costs. This includes securing reliable sources of materials and optimizing logistics.

- Technological Advancements:

- New System Concepts: Adoptions of concepts like CIP (“Cell is pack”) or CIM (“Cell is module”) can reduce the need for additional safety features, lowering costs.

- Improved Lifespan and Reliability: Solid-state batteries’ longer lifespan and reliability can reduce maintenance costs, even if initial production costs are higher.

- Investment in R&D:

- Significant investments by companies like Toyota, QuantumScape, and Samsung in R&D will drive technological advancements, leading to more cost-effective manufacturing processes.

By implementing these strategies, the cost barriers associated with solid-state battery production can be addressed, paving the way for wider adoption.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-can-manufacturing-costs-for-solid-state-batteries-be-reduced/