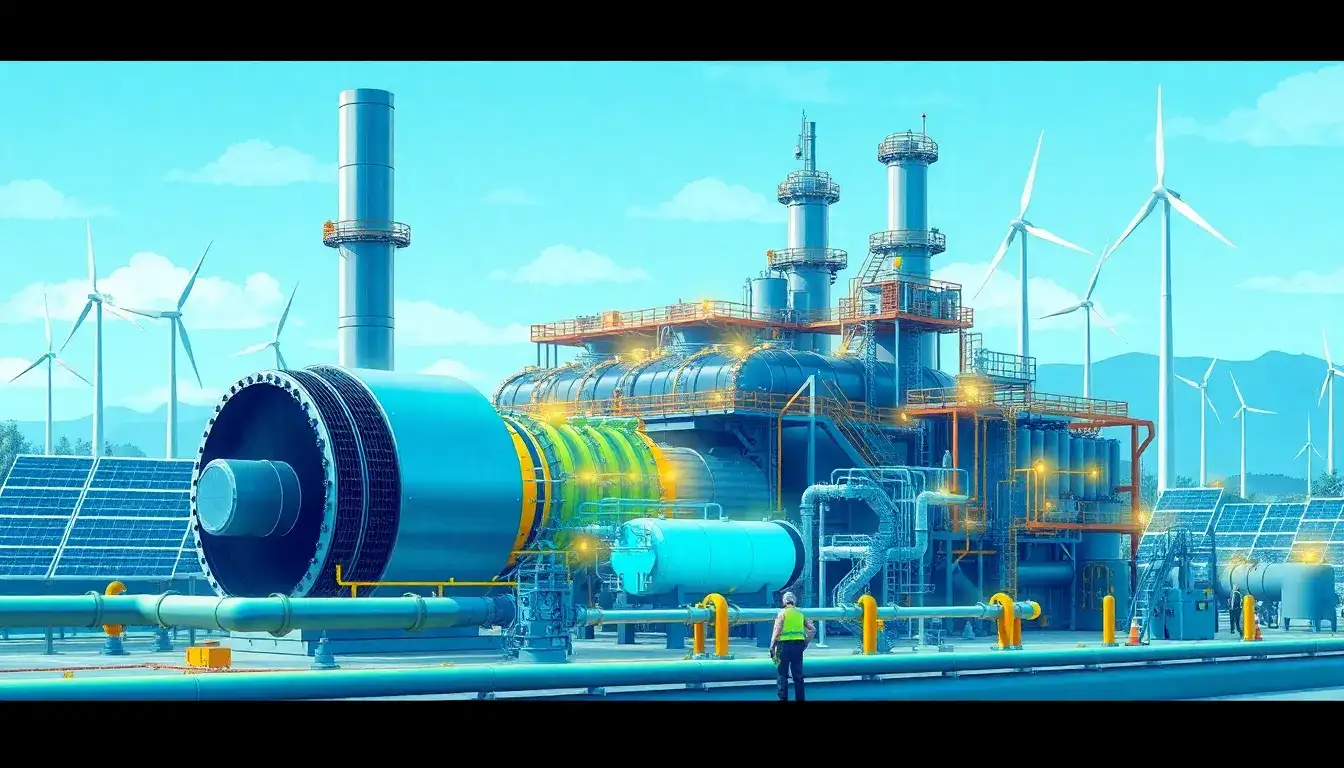

Existing natural gas peaking plants can be upgraded to accommodate hydrogen blends through a combination of turbine modifications, balance-of-plant changes, and operational adaptations. Here is a detailed overview of how these upgrades are carried out:

Technical Upgrades for Hydrogen Blending

- Turbine Modifications: Many existing gas turbines can already operate with low to moderate hydrogen blends. However, to increase the hydrogen share, turbines often require retrofitting components such as burners and combustion systems to handle hydrogen’s different combustion characteristics safely and efficiently. For example, General Electric and Siemens Energy have gas turbine models capable of operating at up to 100% hydrogen with appropriate modifications.

- Balance-of-Plant Changes: Alongside turbine upgrades, auxiliary systems including fuel supply infrastructure, control systems, cooling, and emissions control equipment may need adaptation to manage hydrogen’s properties (like its flame speed and diffusivity) and to mitigate potential emissions such as increased NOx.

- Incremental Blending Capability: Upgrades typically enable incremental hydrogen blending, starting from small percentages (5-20%) and potentially scaling up to 100% hydrogen usage. This allows plant operators to gradually transition, optimizing performance and emissions at each stage. For instance, Duke Energy plans to upgrade its 74 MW DeBary peaking plant in Florida to eventually run solely on hydrogen.

Operational Experience and Pilots

- Various pilot projects have demonstrated hydrogen co-firing at existing natural gas plants with hydrogen blending ranging from about 5% to 44% by volume, showing significant CO2 emissions reductions. For example, New York Power Authority’s Brentwood plant achieved a 14% reduction in CO2 emissions at 35% hydrogen blend, and Georgia Power’s McDonough plant showed a 7% CO2 reduction at 20% hydrogen blend without major turbine modifications.

- Mitsubishi Power noted that at the McDonough-Atkinson plant in Georgia, 20% hydrogen blending was feasible with minimal turbine changes, showcasing that advanced gas turbines can handle hydrogen blends while meeting load demands and emissions standards.

Environmental and Policy Drivers

- Incorporating hydrogen reduces carbon emissions since hydrogen combustion produces no direct CO2. A gas turbine operating on 100% hydrogen would have a carbon intensity effectively dropping to zero from the typical 305–380 g/kWh seen with natural gas alone.

- Supportive federal policies like the U.S. Department of Energy’s Hydrogen Hubs program, EPA regulations, and tax incentives under the Inflation Reduction Act are accelerating interest and investment in hydrogen upgrades at natural gas plants.

Summary

| Aspect | Details |

|---|---|

| Turbine upgrades | Retrofitting burners and combustion systems for hydrogen compatibility; some turbines already hydrogen-capable (up to 100%) |

| Balance-of-plant changes | Fuel handling, control systems, emissions control adaptations to manage hydrogen fuel properties and NOx emissions |

| Hydrogen blending range | Starting from 5-20% hydrogen blends, scalable to 100% hydrogen in advanced retrofits |

| Environmental benefits | Significant CO2 emissions reductions proportional to hydrogen content; near-zero carbon intensity at 100% hydrogen |

| Demonstrated pilots | Multiple U.S. plants successfully co-firing hydrogen blends up to 44% by volume, with operational data supporting feasibility |

| Policy and economic support | Federal incentives, regulations, and emerging hydrogen infrastructure underpin upgrades and investments |

In conclusion, upgrading existing natural gas peaking plants to accommodate hydrogen blends involves targeted turbine and ancillary system retrofits that enable gradual increases in hydrogen use, yielding substantial emissions reductions and supporting the transition to a decarbonized power grid.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-can-existing-natural-gas-peaking-plants-be-upgraded-to-accommodate-hydrogen-blends/