The world’s first iron-air battery storage system has successfully connected to the grid! The concept of “Iron Breathing” marks the beginning of a new era in long-duration energy storage. As renewable energy sources like wind and solar power become more prevalent, their intermittent and variable nature continues to pose significant challenges for the development of new power systems. While short-term storage technologies like lithium-ion batteries can help alleviate daily load fluctuations, they often fall short when addressing energy supply and demand imbalances over days or weeks.

Against this backdrop, the iron-air battery has emerged as a promising candidate for long-duration energy storage, thanks to its extended storage duration, extremely low cost, and high safety. In 2025, the Dutch startup Ore Energy completed the world’s first grid-connected iron-air battery system. This milestone not only signifies the transition of iron-air batteries from laboratory research to practical application but also provides a new storage solution to support the global energy transition.

First Grid Connection: Breaking Ground in Iron-Air Battery Commercialization

The commercialization of iron-air batteries reached a pivotal moment in 2025 when Ore Energy connected the world’s first iron-air battery storage system to the grid at the “Green Village” experimental base of Delft University of Technology. Although this system is relatively small (with a capacity of less than 1 MWh), its operational connection to the grid breaks the long-standing stagnation of long-duration storage technologies that have remained in the concept validation stage. This development offers the industry a practical application reference.

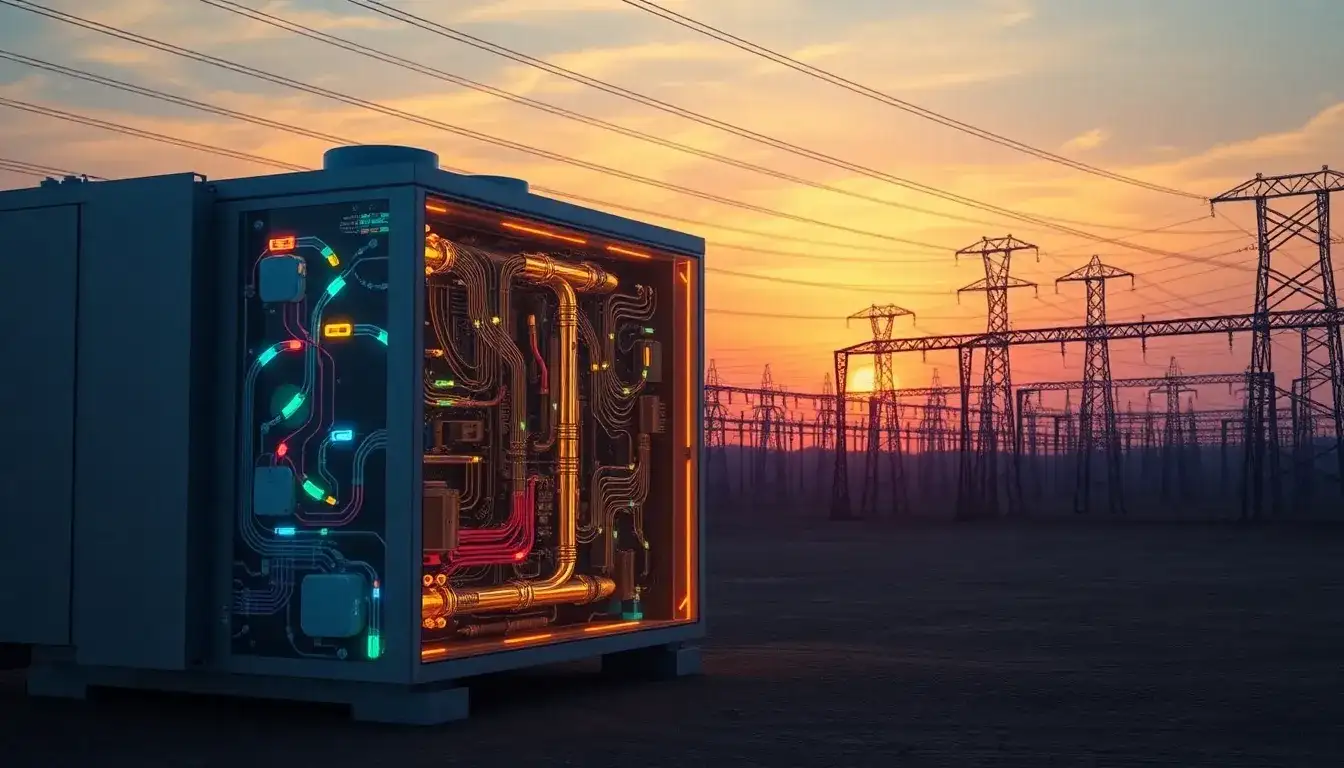

The iron-air battery system developed by Ore Energy features a modular design, allowing the complete 4.2 MWh system to fit inside a standard 40-foot shipping container. This flexibility enables future expansion based on customer demand, making it suitable for small-scale applications like campus microgrids as well as large-scale wind farms and grid-level storage. Notably, this system is the first long-duration storage project in Europe entirely designed, manufactured, and installed locally, aligning with the European Union’s “Clean Industry Agreement” that promotes local clean manufacturing and reduces reliance on external supply chains.

As a spin-off from Delft University of Technology, Ore Energy’s core team has spent eight years developing related technologies, and the independent grid connection point at the experimental base allows for rapid testing of inter-day energy shifting, accumulating data for future commercial applications.

In terms of industry competition, Ore Energy does not operate in isolation within the iron-air battery sector. The U.S. company Form Energy is a pioneer in this field, having raised $1.2 billion in venture capital. After completing a $405 million Series F funding round in October 2024, Form Energy established a manufacturing base in West Virginia and has project reserves ranging from 100 MWh to 8.5 GWh, with multiple projects scheduled to begin operations within the year. In comparison, Ore Energy, established in 2023, is smaller in scale (currently employing around 30 people with a focus on research and development), but the company has ambitious plans to skip long-term small-scale pilots and directly pursue commercial deployment, aiming for an annual production capacity of 50 GWh by 2030. It is also in discussions with numerous commercial clients to deploy systems, particularly targeting the capacity gaps left by retired coal and gas power plants and the energy storage needs of wind projects.

Technical Principles: The Reversible Chemical Reaction of “Rusting and De-rusting”

The core principle of the iron-air battery is based on the redox reaction of iron. Although this chemical process was proposed in the 1960s, it has long faced technical challenges, particularly the difficulty of “de-rusting.” Today, companies like Ore Energy have optimized this technology, revitalizing this “ancient” principle. The working mechanism can be summarized as a “breathing” charge and discharge cycle: During discharge, the iron anode, submerged in a water-based electrolyte, reacts with oxygen from the air, oxidizing iron into rust (iron oxide) while releasing electrical energy. Upon charging, external electrical energy is input into the system, reducing rust back to metallic iron, while oxygen is “vented” from the battery. As Ore Energy co-founder Dr. Aytac Yilmaz puts it, “Like lungs, it transforms iron into rust and back to iron with each breath.”

This reaction process does not rely on scarce materials like lithium, cobalt, or nickel, using only iron and air as core raw materials, which significantly reduces dependency on special resources. The key to the technological breakthrough lies in addressing the industry pain point of “de-rusting.” While iron oxidation (rusting) is a natural process, efficiently and stably reducing rust back to iron in the battery system presents challenges such as low reaction efficiency and interference from by-products. Although Ore Energy has not disclosed the specific composition of the anode (only revealing that other substances were added to iron), the operation of their grid-connected system has already demonstrated the practicality of this technology.

Compared to lithium-ion batteries, the greatest advantage of iron-air batteries is their extended storage duration—while mainstream lithium-ion batteries can only supply power continuously for 4 to 12 hours, iron-air batteries can achieve over 100 hours of sustained discharge. This capability allows them to effectively respond to several consecutive days of calm or rainy weather, providing a time-shifting energy buffer for the stable integration of renewable energy into the grid.

Furthermore, the structural design of this technology is remarkably simple, consisting primarily of an iron anode, a “membrane-like” cathode, and a water-based electrolyte, without complex components. This simplicity not only reduces manufacturing difficulty but also lays the groundwork for future large-scale production. The long-term research conducted at Delft University of Technology has thoroughly validated this system in terms of material compatibility and reaction stability, thereby minimizing technical risks for commercialization.

Core Advantages: Low Cost, High Safety, and Long Storage Duration

In the competitive landscape of long-duration storage technologies, the iron-air battery stands out due to its three key advantages: low cost, high safety, and exceptionally long storage duration, making it highly competitive in the market, especially in meeting the grid’s long-cycle energy regulation needs. The cost advantage of iron-air batteries is particularly notable. Iron is one of the most abundant metals in the Earth’s crust, with an annual production exceeding 1.8 billion tons, making it inexpensive and easy to source. Air, on the other hand, is an inexhaustible free resource. This unique raw material characteristic allows Ore Energy to achieve an industry-leading cost control, disclosing that its battery costs only €16 per kWh, while lithium-ion batteries were approximately ten times that price in 2023. For long-duration storage projects that require large-scale deployment, cost is a crucial factor in determining the viability of technology, and the “affordable” pricing of iron-air batteries positions them favorably for applications such as replacing fossil fuel backup power sources and supporting wind and solar projects.

Safety is another critical competitive advantage. The iron-air battery utilizes a water-based electrolyte, unlike the organic electrolytes commonly found in lithium-ion batteries, which are flammable and explosive. Many recent global energy storage facility fire incidents have been linked to these organic electrolytes. In contrast, the water-based electrolyte used in iron-air batteries is non-flammable and non-explosive, fundamentally eliminating the risks of fire and explosion in storage systems. For grid-level and urban periphery storage projects, safety is directly related to environmental and resident safety, and this feature of iron-air batteries clears safety hurdles for deployment in densely populated areas and critical grid points.

The exceptionally long storage duration aligns perfectly with the integration needs of renewable energy. The output fluctuations of wind and solar energy are not limited to daily cycles (e.g., daylight hours versus nighttime) but also include significant multi-day and multi-week variations (e.g., continuous wind for three days or a week of rain). Short-term storage technologies are inadequate to cover such long-duration fluctuations, whereas the 100-hour discharge capability of iron-air batteries enables “multi-day energy time-shifting”—storing electrical energy when wind and solar output is excessive and continuously releasing it during periods of insufficient output, thus effectively smoothing out long-term energy supply and demand fluctuations. For example, in Europe, countries like the Netherlands experience insufficient sunlight but have abundant wind energy resources. The multi-day fluctuations in wind energy significantly impact grid stability, and iron-air batteries can fill this regulatory gap, reducing reliance on coal and gas power plants and facilitating the transition of the energy structure.

Industry Competition and Future Challenges: Opportunities and Trials in the Long-Duration Storage Arena

The iron-air battery is not an isolated technological innovation but rather an important player in the global competition for long-duration energy storage. The International Energy Agency (IEA) predicts that by 2050, global long-duration storage installations will need to reach terawatt-hour (TWh) levels, prompting various technological pathways (such as pumped hydro storage, compressed air energy storage, and flow batteries) to accelerate competition. Iron-air batteries must identify their position within this industry landscape while also addressing their own technical shortcomings.

From the perspective of industry competition, the iron-air battery sector has formed a preliminary “dual stronghold” situation between the U.S. and Europe. The U.S. company Form Energy, benefiting from its first-mover advantage, leads in financing scale, capacity construction, and project reserves—its $1.2 billion funding has provided ample resources for research, production, and its West Virginia manufacturing base has enabled commercial-scale production capacity. With 8.5 GWh of in-hand projects, Form Energy validates the market demand for this technology. Although Ore Energy is a latecomer, its advantage in locally designed and manufactured solutions aligns well with EU policy directions (such as the “Clean Industry Agreement,” which plans to invest over €100 billion to support local clean manufacturing), and its strategy to rapidly advance commercial deployment may allow it to gain an edge in the European market.

In addition to these two companies, numerous research institutions and enterprises worldwide are exploring iron-air battery technology, and the future competition within the industry will gradually shift from technology validation to cost control, cycle life, and system efficiency.

Despite its promising prospects, the iron-air battery faces three core challenges. First, its energy density is relatively low. Compared to lithium-ion batteries (with energy densities typically ranging from 150-300 Wh/kg), iron-air batteries show significantly lower energy density, resulting in larger volumes—meaning a 4.2 MWh system must be housed in a 40-foot container, making it unsuitable for mobile applications like electric vehicles that are sensitive to space and weight, thus limiting its use to fixed storage domains.

Second, its cycle life remains to be validated. The currently grid-connected systems are still in pilot stages, and there is insufficient data to support long-term operational cycle life (the number of charge and discharge cycles), while energy storage projects typically require a lifespan of 20-30 years. A lack of cycle life would significantly increase replacement costs and operational pressures.

Third, system efficiency needs improvement. The round-trip efficiency (energy loss during the charge and discharge process) of iron-air batteries is about 40-50%, which is lower than the 85%+ efficiency of lithium-ion batteries and below the 70-80% efficiency of pumped hydro storage. High energy loss will reduce energy utilization efficiency, making it less competitive in scenarios where efficiency is crucial (such as grid frequency regulation).

Going forward, advancements in materials science (such as optimizing anode formulations to improve reaction efficiency) and upgrades in system integration technology (like using intelligent control to reduce energy loss) are expected to gradually address these shortcomings. The unique value of iron-air batteries in the long-duration storage sector ensures they will not completely replace other storage technologies but will complement lithium-ion batteries and pumped hydro storage—where lithium-ion batteries handle short-term peak shaving and frequency regulation, iron-air batteries manage long-duration inter-day adjustments, and pumped hydro serves the capacity support for large grids, collectively forming a diversified and complementary energy storage system.

For companies like Ore Energy and Form Energy, the next critical step involves validating the stability of their technologies through more commercial projects while expanding capacity and optimizing costs to secure a position in the global long-duration energy storage market.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/global-milestone-first-iron-air-battery-system-connected-to-power-grid-marks-new-era-in-long-duration-energy-storage/