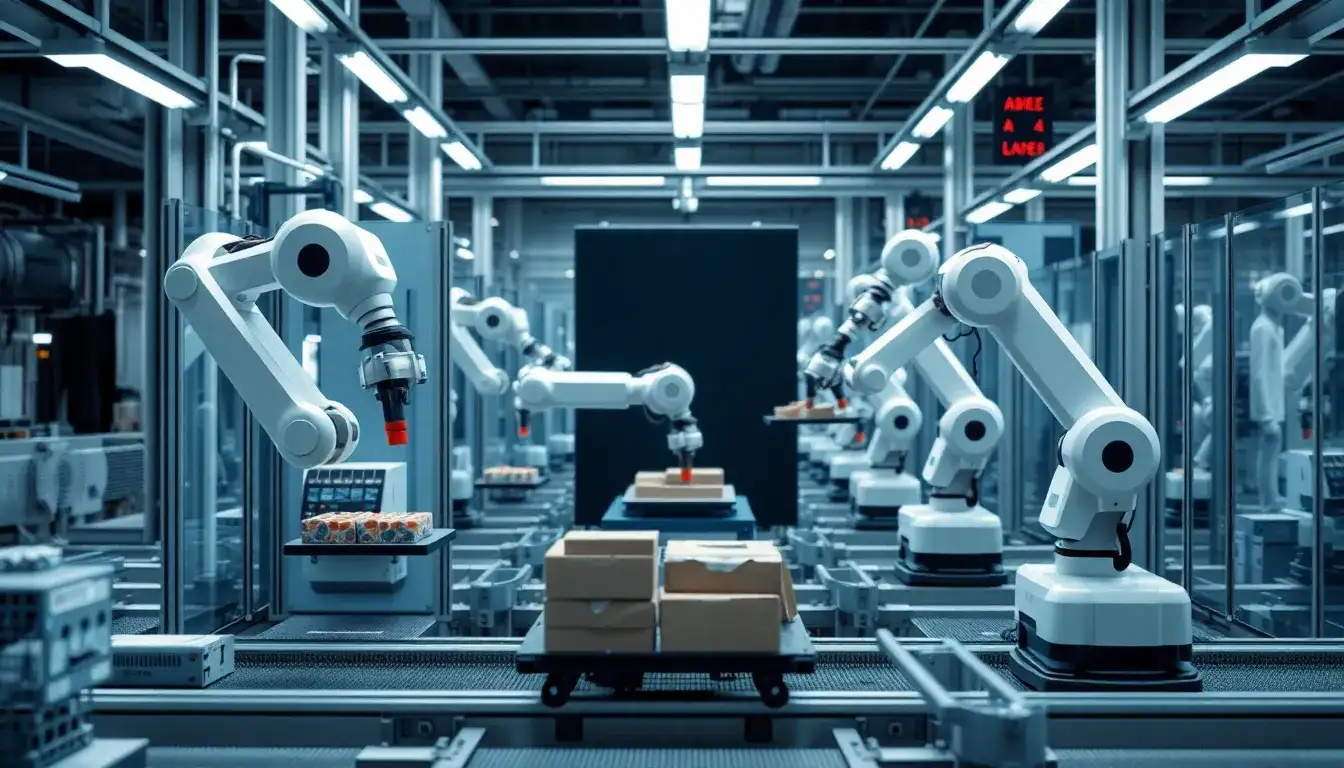

In the wave of smart manufacturing, Delta’s SCARA robots play a crucial role on production lines by enhancing efficiency through their three main characteristics: high efficiency, precision, and flexibility. Today, we will explore five practical application scenarios that demonstrate how to effectively utilize Delta’s SCARA robots to maximize their capabilities and easily resolve production challenges.

Scenario 1: Sealing and Gluing – Reducing Teaching Time by 87%

On a production line for electric irons in East China, ensuring the accuracy of glue application on the base plate typically requires over four hours of robot teaching, significantly impacting overall production efficiency. Delta has employed SCARA industrial robots along with a vision system, combined with proprietary glue dispensing analysis software, to quickly generate DXF trajectory parsing plans. This approach has reduced the teaching time to under 30 minutes, greatly shortening the hours needed for the sealing glue process.

Scenario 2: Following Operations – Optimizing Process Efficiency in Real-Time

In the wet wipes packaging production line, the process of attaching wet wipe covers is the final step, and traditional static methods are not very efficient. Delta leverages the synchronous tracking and auto-planning motion features of SCARA industrial robots, alongside powerful visual monitoring algorithms from the vision system, to capture the position of wet wipe covers in real-time as the conveyor belt runs. This allows for sequential operations such as positioning, grabbing, gluing, and attaching, achieving true online following operations and significantly reducing production time.

Scenario 3: Flexible Feeding – Rapidly Picking Up Various Parts

On an assembly line for automobiles, the variety and specifications of assembled parts can complicate material supply and production coordination. Delta has developed a flexible feeding system centered on SCARA industrial robots, integrating a vision system and a flexible vibrating bowl. This system can manage the feeding, arrangement, identification, positioning, picking, and sorting of various sizes and irregular materials with minimal human intervention, meeting the demands for high precision, fast-paced, and low-damage production.

Scenario 4: High-Speed Sorting – Enhancing Speed and Accuracy

At a cosmetics production factory in South China, customers have requested advanced optimization for the process of quickly and accurately loading various colored powder compacts into their respective boxes. Delta’s solution combines SCARA robots with a vision system to achieve a grabbing precision of ±0.1mm on a high-speed conveyor line. This enables the rapid placement of different colored powders into the correct boxes, enhancing both production quality and operational efficiency.

Scenario 5: Complex Assembly – Executing Various Intricate Processes

The complexity of assembling printed circuit boards (PCBs) continues to increase, and a single robot application is no longer sufficient to meet the demands for precision and synchronized automation. Delta utilizes a collaborative approach with multi-joint DRV series robots and DRS series SCARA robots, simulating a “dual-hand collaboration” mode. The vision system facilitates rapid point correction and high-precision alignment, allowing the two robots to work together to complete complex tasks such as insertion, locking, and inspection, greatly enhancing assembly accuracy.

Delta’s SCARA robots offer a combination of vision guidance, software empowerment, and collaborative operations, providing businesses with highly adaptable and reliable automation solutions. Choosing the right robot makes production easier!

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/exploring-five-application-scenarios-of-deltas-scara-robots-in-smart-production-lines/