Can tubular solar panels withstand pressure? How to connect them?

1. Yes, tubular solar panels can withstand significant pressure, 2. They are designed with robust materials for durability,** 3. Proper installation methods enhance their resilience,** 4. Connecting them requires specific techniques for optimal performance. Tubular solar panels are engineered to resist various environmental stresses, including wind and snow loads. Their cylindrical shape provides structural integrity that enhances their ability to withstand external forces. When installed correctly, they can effectively harness solar energy even in challenging weather conditions. The connections made between these panels are crucial for their efficiency and require specialized fittings and knowledge to ensure maximum production and safety.

1. STRUCTURAL INTEGRITY OF TUBULAR SOLAR PANELS

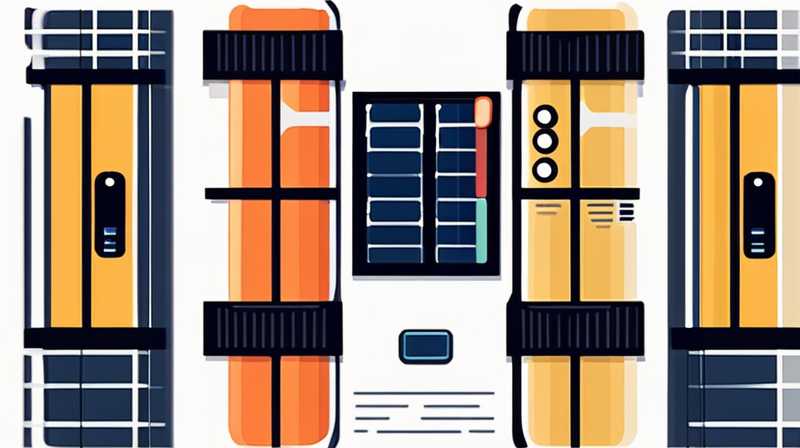

Tubular solar panels, characterized by their cylindrical design, are created to endure harsh environmental conditions. Their unique form contributes to their overall structural resilience. This design helps to distribute forces evenly across the panel surface, reducing the chances of localized failure. Moreover, the materials used in their construction—typically high-quality aluminum and tempered glass—add to their strength and longevity. These materials are selected not only for their light weight but also for their capability to handle pressures like snow loads and wind resistance.

The ability to withstand broad types of pressure is a significant advantage, making tubular solar panels suitable for various environments, from residential rooftops to large-scale commercial installations. As such, they offer a reliable solution for harnessing solar energy, even in regions with extreme weather patterns. The pressure endurance of these panels contributes to their appeal among consumers concerned about durability and performance over an extended period.

2. INSTALLATION TECHNIQUES FOR ENHANCED PRESSURE RESILIENCE

Achieving the necessary structural integrity starts with professional installation. It is of utmost importance to follow established guidelines to bolster the panels’ capacity to withstand force. Factors such as the angle of installation, the materials used for mounting, and the chosen orientation all play pivotal roles. Properly securing these panels onto the mounting infrastructure is critical, ensuring they remain stable under various pressure conditions. Each installation site introduces specific variables that should be taken into account.

In areas that experience heavy snowfall or high winds, additional reinforcements may be necessary. Professionals often recommend using bracing systems or specialized mounts that offer superior support and can effectively manage the stress exerted on the panels. Such precautions not only preserve the structural integrity of the solar panels but also enhance their overall performance, ensuring that they generate electricity efficiently regardless of weather conditions. Installation in challenging geographic locations necessitates meticulous planning and consideration of environmental factors that could impact the panels’ longevity.

3. TECHNICAL ASPECTS OF CONNECTING TUBULAR SOLAR PANELS

To maximize efficiency, an understanding of how to connect tubular solar panels is essential. Connections play a pivotal role in the overall functionality of the solar system. Knowing how to link these panels ensures seamless energy flow and optimizes performance. Typically, tubular panels are interconnected in either series or parallel configurations, or a combination of both, depending on the desired voltage and current output.

In series connections, the voltage increases while the current remains constant. Conversely, connecting panels in parallel results in increased current but the voltage does not change. Selecting the appropriate connection type depends on the specific requirements of the solar array and the inverter capacity. Proper wiring, including the selection of suitable cable gauges and connectors, is also critical in minimizing energy losses.

It is vital to ensure all connections are secure and free from potential points of failure. Using weather-resistant connectors and ensuring all electrical components comply with safety standards protects against environmental factors that could lead to degradation over time. Careful attention to these details not only enhances the performance of the system but also extends the operational lifespan of the solar panels.

4. MAINTENANCE PRACTICES FOR OPTIMAL PERFORMANCE

Regular maintenance of tubular solar panels is essential for ensuring their sustained pressure resistance and optimal energy production. Scheduled inspections allow for early identification of any possible issues arising from environmental wear or pressure strains. Typical maintenance procedures may include: cleaning the panel surfaces, tightening connections, and checking for any signs of physical damage.

Cleaning the panels helps maintain their efficiency, as dirt and debris can obstruct sunlight and negatively impact energy production. Periodic inspections should also include a thorough examination of the mounting structures to identify any signs of corrosion or wear, which could compromise the panels’ stability. Furthermore, verifying the integrity of electrical components, such as the inverter and batteries, aids in retaining the overall efficiency of the solar power system.

In more extreme climates or installations with high pressure exposure, maintaining an even higher frequency of inspections may be prudent. The ultimate objective of these practices is to ensure that both the physical and electrical components of the system function optimally, maximizing energy generation while minimizing potential risks associated with pressure-related failures.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE AVERAGE LIFESPAN OF TUBULAR SOLAR PANELS?

Typically, tubular solar panels have a lifespan ranging between 25 to 30 years. This longevity is contingent upon various factors, including the quality of materials, installation techniques, and maintenance practices. Panels manufactured with high-quality materials and properly maintained can last toward the upper end of this range, consistently delivering efficient energy production even after two decades. Furthermore, manufacturers often provide warranties that guarantee performance over a specified time, offering consumers additional reassurance. Ultimately, choosing reputable manufacturers and adhering to maintenance schedules can significantly influence the lifespan of tubular solar panels.

HOW DO WEATHER CONDITIONS AFFECT TUBULAR SOLAR PANELS?

Weather conditions can significantly influence the performance and resilience of tubular solar panels. Extreme temperatures, heavy rainfall, hail, and strong winds can pose various challenges to solar panel efficiency. For instance, while rain can help clean the surface of the panels, prolonged periods of cloud cover can reduce energy production. However, tubular solar panels are designed to withstand harsh weather due to their robust construction. Innovative designs and technology ensure that they remain effective even under adverse conditions, making them suitable for diverse geographic locations. As such, proactive maintenance and careful installation can mitigate the impacts of weather on their performance.

IS PROFESSIONAL INSTALLATION NECESSARY FOR TUBULAR SOLAR PANELS?

While technically, a knowledgeable DIY enthusiast may attempt to install tubular solar panels, it is advisable to seek professional installation services. Professionals possess the expertise to ensure that the panels are installed correctly and securely, optimizing their performance while adhering to safety regulations. Moreover, they can evaluate environmental factors unique to the installation site that may affect panel efficiency. Professional services also often include a warranty covering the installation process, providing peace of mind for homeowners and businesses alike. Ultimately, the added investment in professional installation can significantly enhance the performance and longevity of tubular solar panels.

In summary, tubular solar panels exhibit a remarkable capacity to endure substantial pressure, pivotal for their long-term functionality. Their construction with durable materials, combined with expert installation techniques, solidifies their place as reliable energy solutions. The process of connecting these panels requires careful consideration of technical specifications to ensure optimal performance. Ongoing maintenance not only maximizes efficiency but also prolongs their operational life, ultimately resulting in an effective renewable energy source. As solar technology continues evolving, staying informed about installation best practices and maintenance strategies is essential for harnessing the full potential of tubular solar panels. Adopting these measures contributes to energy sustainability while safeguarding your investment. Users can feel confident in their ability to select and maintain tubular solar panels, enjoying the benefits of solar energy for many years.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/can-tubular-solar-panels-withstand-pressure-how-to-connect-them/