Yes, there are specific pipe material characteristics that reduce friction losses more effectively, primarily related to the smoothness of the pipe’s interior surface.

Pipe Materials and Friction Loss Reduction

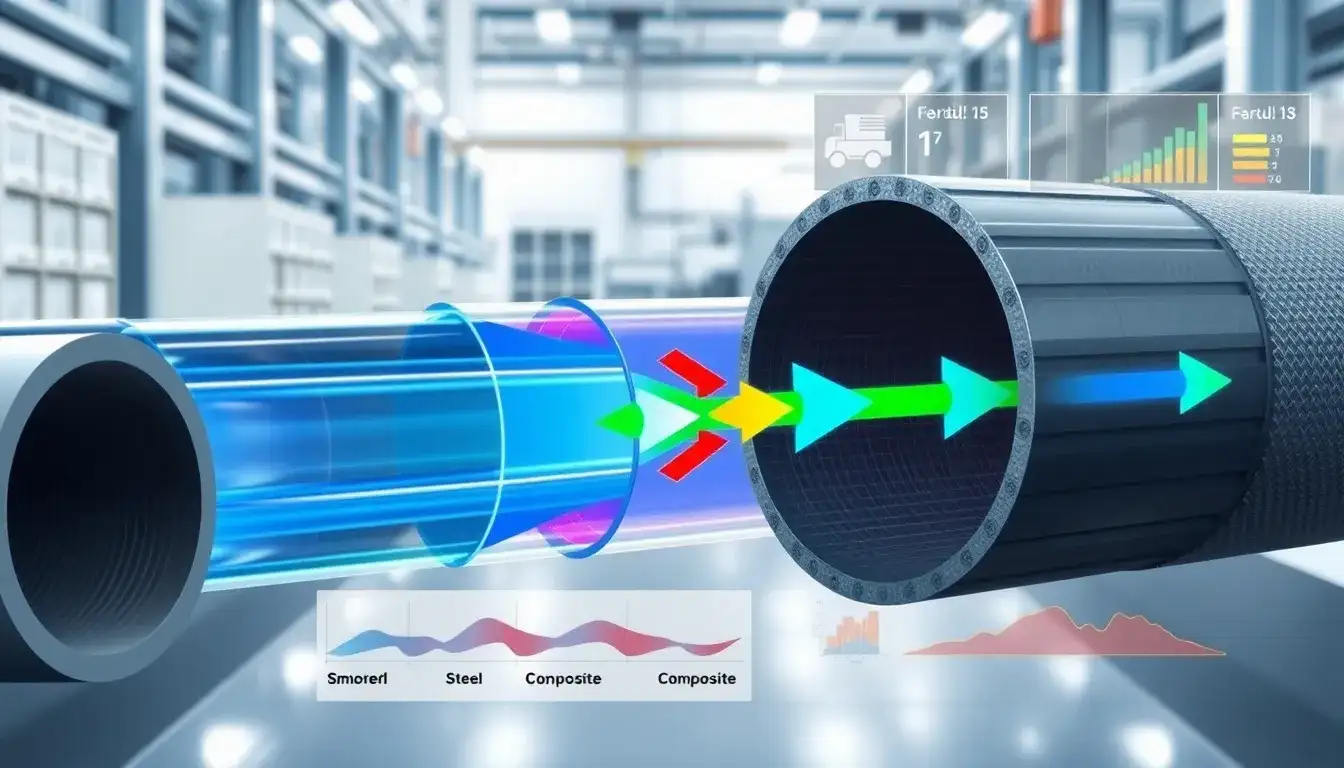

- Smoother Interior Surfaces: Pipe materials that have smoother interior walls reduce friction losses because they provide less resistance to fluid flow. Smoother surfaces prevent turbulence and reduce the energy lost when fluid moves through the pipe. Therefore, selecting pipes with a smoother surface finish inside can significantly reduce friction energy loss.

- Corrosion Resistance: Materials that resist corrosion maintain a smooth interior longer, preventing roughness that develops from corrosion, which increases friction and causes blockages. Thus, corrosion-resistant materials indirectly help reduce friction loss by preserving smoothness over time.

- Pipe Type Examples: While the specific materials are not detailed in the search results, common industrial choices that offer smoother surfaces and corrosion resistance include PVC, HDPE, and certain coated metals. Metal pipes like stainless steel or pipes with internal linings are often preferred where smoothness and durability are critical.

Additional Factors Affecting Friction Loss

Regardless of pipe material, friction loss also depends on:

- Pipe diameter (larger diameters reduce friction loss)

- Pipe length (shorter pipes reduce friction loss)

- Number and type of pipe fittings, elbows, and valves (fewer and more gradual turns reduce turbulence and friction)

Summary

Choosing pipe materials with smooth, corrosion-resistant interior surfaces effectively reduces friction losses. This, combined with design choices like larger diameters, shorter lengths, and minimizing sharp turns or fittings, optimizes pipe flow efficiency and reduces energy consumption in pumping systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/are-there-specific-pipe-materials-that-reduce-friction-losses-more-effectively/