When AI Vision Technology Meets Metal Manufacturing

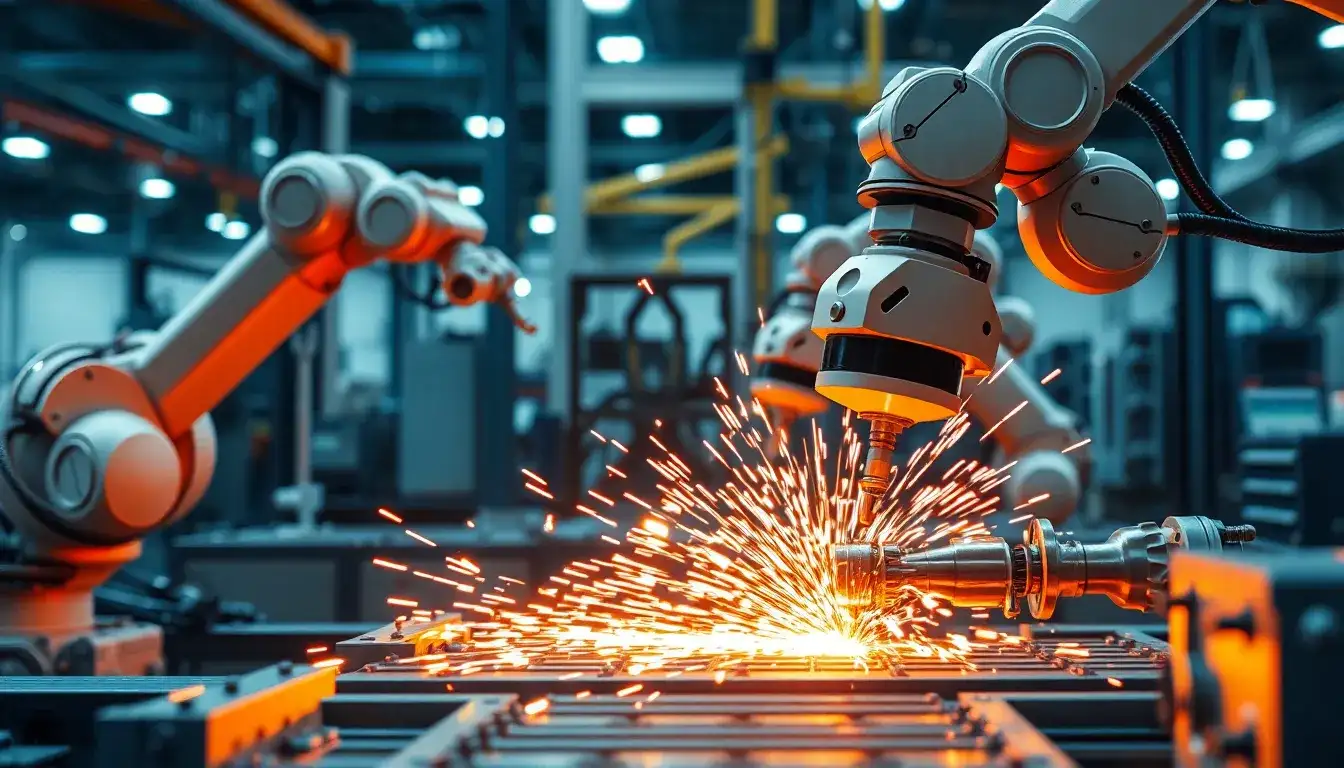

At Tosec BV in the Netherlands, visitors encounter a typical scene of a custom metal processing facility, with the sounds of plasma cutting tables, laser cutters, and welding arcs humming in the background. However, as one delves deeper into the workshop, it becomes clear that this is no ordinary processing shop.

A robot is feeding workpieces into a deburring machine, while a parts sorting system employs dual robotic arms to pick up cut blanks and classify them into unique tower storage racks. The grinding and slag cleaning robots automate the heavy edge finishing processes of the sheets, notably utilizing end-effectors that grip traditional angle grinding tools, with cameras monitoring the entire work unit in real-time.

What stands out are the identifiers on these automated units—the artistic letter “T,” the trademark of Tosec and its parent company, Tollenaar Industries. As a family business, Tollenaar operates across the Netherlands, Germany, and South Africa. Through its subsidiary Teqram, the Tollenaar Industrial Group has developed vision-based automation systems tailored for custom processors and similar multi-product production environments.

A common theme across nearly all of the company’s automation projects is the absence of manual programming or operator use of teaching devices. Instead, the automation is driven entirely by AI-powered vision technology.

Beginning with Vision

Frans Tollenaar, the sales director of Teqram, along with his brother Roland Tollenaar, the chief technology officer, points to a vision-guided robot named EasyGrinder, which is processing the edge finishing of plasma-cut sheets. This robot is equipped not with specialized grinding heads, but with a conventional angle grinder, a tool originally designed for manual operation, fitted with standard grinding discs.

“We chose manual tools after careful consideration, primarily because they allow for a rich variety of machining processes. Companies like 3M have visited us and were amazed at the exceptional performance we achieved with these tools, as we have utilized them to their fullest potential,” Frans explains.

Three Key Elements of the Work Unit

The success of this system relies on three main elements. First is the vision technology, which eliminates common barriers that impede automation in high-mix, low-volume production scenarios: robot programming. Frans points to the camera above the grinding unit—EasyEye. This device integrates time-of-flight laser distance sensors and high optical zoom lenses.

The manual grinding tool is mounted on the robot’s end effector via a hinged mechanism, designed to optimize the working pressure of specific tools. “This camera generates three-dimensional coordinates and associates them with captured pixel points,” he elaborates. “Essentially, it provides spatial pixel coordinates, which we use with vision algorithms to accurately determine the actions the robot needs to perform. The scanner integrated into the robot’s end effector provides detailed perspectives and the necessary information for precise machining.”

Once the robot identifies a specific workpiece, it must extract the features to be processed. At this point, specialized application logic takes over. If the robot “sees” a specific combination of workpiece features, it automatically selects the corresponding tool to handle those features. “Our goal is to have technology operate like humans,” Frans states. “Just like you would instruct a worker to ‘please grind these parts and round the edges,’ we merely provide simple instructions, and the robot autonomously completes the task.”

About Positioning Technology

Frans points to the workbench, EasyFlipper, which opens up during robot operations and holds the sheets in place using strong magnetic forces. After the robot completes processing one side, the clam-shell closes and flips the workpiece. This technology is the second key element enabling such multi-product automation: a simple and flexible gripping system that requires no human intervention. It is important to emphasize that this is a typical multi-product production environment where every part may differ. If operators had to readjust the fixtures after each grinding cycle, the value of automation would be significantly diminished.

About Pressure Control

The design of manual tools is inherently ergonomic, meaning they must apply specific angles and pressures to the workpiece and were not originally designed for robotic use. So, how can a robot adaptively operate without relying on programming? To explain this principle, Frans points to the protruding hinged component of the end effector, which acts as a counterweight. “We patented this. The counterweight applies precise pressure, and we use encoders to read angle data.” The software system integrates visual data, proprietary processing logic for each tool, counterweight parameters, and encoder readings to dynamically adjust pressure, feed rates, and rotational speeds to complete part processing.

For example, in the operation of the robot holding the grinding wheel horizontally, the angle of the grinding disc can vary between 0-30°. By optimizing the counterweight design, we ensure the tool maintains precise pressure at different entry angles. For vertical tool operations—such as rounding the edges of plates using an angle grinder—precise pressure control is achieved through an independent spring mechanism.

Cutting, Leveling, and Deburring

Today, Teqram has established an expansive R&D center just a block away from Tosec. This center features rows of robots and multiple testing areas that are validating flexible automation solutions for various industrial applications. The focus remains firmly on custom metal manufacturing. Back in the Tosec workshop, numerous concepts are applied in practice. “We developed an automated unloading system where robotic arms can grasp parts weighing up to 1300 pounds,” Frans explains. “The user interface is very intuitive; the system asks the operator how to group parts, whether by project or downstream processing requirements.”

While this system cannot handle every cutting profile, the robot can flexibly grasp complex profiles and make multiple attempts before determining if a part is stuck and requires manual handling; if it fails, it automatically moves on to the next part. “The system heavily relies on the cutting outcome,” Frans emphasizes. “It requires sufficiently wide gaps and ample spacing between parts to ensure stable separation. Nonetheless, the system is designed to handle parts of various sizes—capable of picking up small nested parts, and in some installation scenarios (not implemented by Tosec), it can even transport oversized blanks that occupy most of a cutting table.”

Continuing down the production line, robots feed materials into the deburring machine, and Teqram has also developed similar technology for leveling systems. In the leveling process, vision technology plays a multidimensional role: recognizing parts picked up by the robotic arms, monitoring the process of flipping sheets for secondary processing, and measuring final flatness to classify results—distinguishing between acceptable products and waste, which are placed in different trays. When feeding parts to the deburring machine, robots can place multiple parts side by side on a conveyor belt. The vision system simultaneously monitors the unloading station after deburring, automatically slowing down or pausing operations until the bottleneck is cleared. “It feels as natural as human operation,” Frans describes.

Breaking Through Automation Constraints

Modern metal processing equipment has achieved exceptional productivity, but as production efficiency increases, downstream bottlenecks are more likely to occur—often in manual operations. Even in the most automated processing plants today, “human islands” still exist: laser cutting can operate unattended overnight, but the next morning, workers are still required to sort through hundreds of cut blanks and manually feed them into the deburring or leveling machines.

As demonstrated by the automation solutions adopted by Tosec and developed by Teqram, vision and artificial intelligence technologies showcase significant potential—even in the most complex processing shops. With ongoing innovation, these “human islands” will gradually disappear.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/ai-vision-technology-revolutionizes-metal-manufacturing-processes/