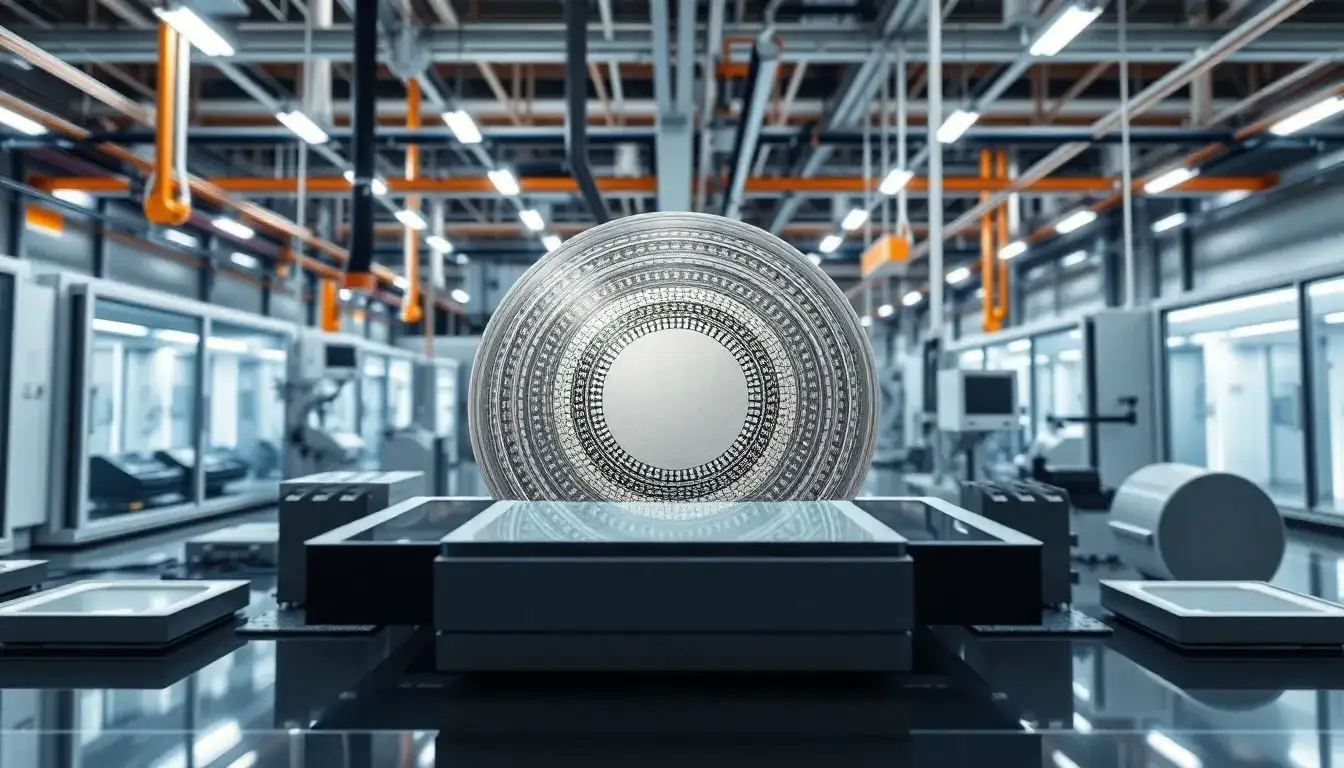

Changfei Advanced Silicon Carbide Wafer Production Line Achieves Mass Production

On May 28, Changfei Advanced’s Wuhan base successfully achieved mass production with the first 6-inch silicon carbide wafer rolling off the production line. The project boasts a total investment of 20 billion RMB and covers an area of 498 acres, with the first phase alone occupying 344 acres. Upon reaching full capacity, it will have the capability to produce 360,000 wafers and 61 million silicon carbide power modules annually.

According to Li Gang, the general manager of Changfei Advanced’s Wuhan wafer factory, the newly produced 6-inch silicon carbide wafers are primarily used in the main drives of new energy vehicles. “They have passed automotive reliability standards certification, with the initial yield reaching 97%,” he stated. The production is expected to ramp up to 3,500 wafers per month by the end of the year.

Sic, as a representative of third-generation semiconductors, has unique advantages in high-voltage and high-power applications due to its material properties. Silicon carbide power devices are more efficient and smaller compared to silicon-based devices, leading to rapid penetration in sectors such as new energy vehicles, photovoltaics, and energy storage.

Previously, Changfei Advanced completed a base in Wuhu, Anhui, with an annual production capacity of 60,000 silicon carbide MOSFET wafers. The Wuhan base is a crucial part of its expansion plans. In August 2023, Changfei Advanced signed a cooperation agreement with the Wuhan East Lake High-tech Zone for the research and production base project of third-generation semiconductor power devices.

“We visited Wuhan in July 2023 for site selection, and at that time, the surrounding area was still a village. After signing the agreement, we received support from various levels of government. Construction began in September, and the factory was completed and put into production in just 21 months, which is unimaginable in other places,” Li Gang noted.

During the planning phase, Changfei Advanced aimed for the localization of high-end silicon carbide functional device chips. Li Gang believes that the often-discussed “overcapacity of silicon carbide” is concentrated in lower-end production; in fact, less than 10% of domestic silicon carbide chips used in new energy main drives have been developed, indicating a significant market replacement opportunity.

In the past month, the Wuhan base has welcomed customers and partners from around the globe. Li Gang mentioned, “Everyone is quite satisfied with the mass production status of the Wuhan base. Some customer products are currently undergoing verification, and they may officially enter mass production in a few months.”

Currently, the core task of the Wuhan base is to quickly complete the ramp-up of production capacity. Li Gang estimates that by the end of this year, the monthly production capacity can reach 3,500 wafers.

In addition to the first wafer rolled off the production line, the Changfei Advanced Wuhan base has eight other products currently in the validation stage, which is expected to reach 12 by the end of the year. Once fully operational, the project can meet the demand for high-end chips for 1.44 million new energy vehicles.

Young “Unicorns” in Silicon Carbide Production

This year has seen a surge in silicon carbide production capacity, with manufacturers like Sanan Optoelectronics, CoreLink Integrated, and Silan Microelectronics launching 8-inch silicon carbide production lines, expected to achieve mass production this year. Compared to them, Changfei Advanced is quite young, but if the Wuhan base can reach its production targets on schedule, it will become one of the largest silicon carbide semiconductor manufacturers in China.

Changfei Advanced Semiconductor was born out of Changfei Fiber Optics. According to Zhuang Dan, executive director and president of Changfei Fiber Optics and chairman of Changfei Advanced, the company anticipated that power semiconductors for the new energy vehicle industry would be a significant market direction and led a joint investment team to complete the acquisition of Changfei Advanced.

Following that, Changfei Advanced Semiconductor brought in over a hundred core team members from international semiconductor manufacturers, successfully achieving mass production at its Wuhu base, covering applications from photovoltaics, energy storage, and charging stations to new energy vehicles.

In August 2023, Changfei Advanced Semiconductor announced completion of over 3.8 billion RMB in Series A financing, setting a record for funding in the third-generation semiconductor sector this year. The group of investors was impressive, including Optics Valley Jin控, Zhejiang State-owned Assets Reform Fund, funds under China International Capital Corporation (CICC), Haitong M&A Fund, and funds under Guoyuan Jin控 Group.

Among them, Optics Valley Jin控 is the highest contributing new shareholder. Qin Jun, chairman of Optics Valley Jin控, stated that Changfei Advanced is a leading manufacturer of third-generation semiconductor power devices in China, and the Wuhan base project is of great significance for building a leading manufacturer of silicon carbide chips and improving the compound semiconductor industry chain.

Subsequently, the Changfei Advanced Wuhan base was rapidly launched. This factory, with an investment of over 20 billion RMB, is the first fully automated silicon carbide device manufacturing benchmark factory in China. According to Li Gang, “All steps in wafer production are completed through an automated crane system, ensuring cleanliness while further improving production efficiency and product yield. Currently, the factory can operate 24 hours a day with just over 80 production line workers.”

In the future, the Changfei Advanced Wuhan base has reserved an additional 154 acres for phase two development. According to the company’s chairman, Zhuang Dan, once the first phase reaches full production, phase two construction will be initiated.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/advancements-in-semiconductor-manufacturing-longhua-advanceds-new-sic-wafer-production-in-wuhan/