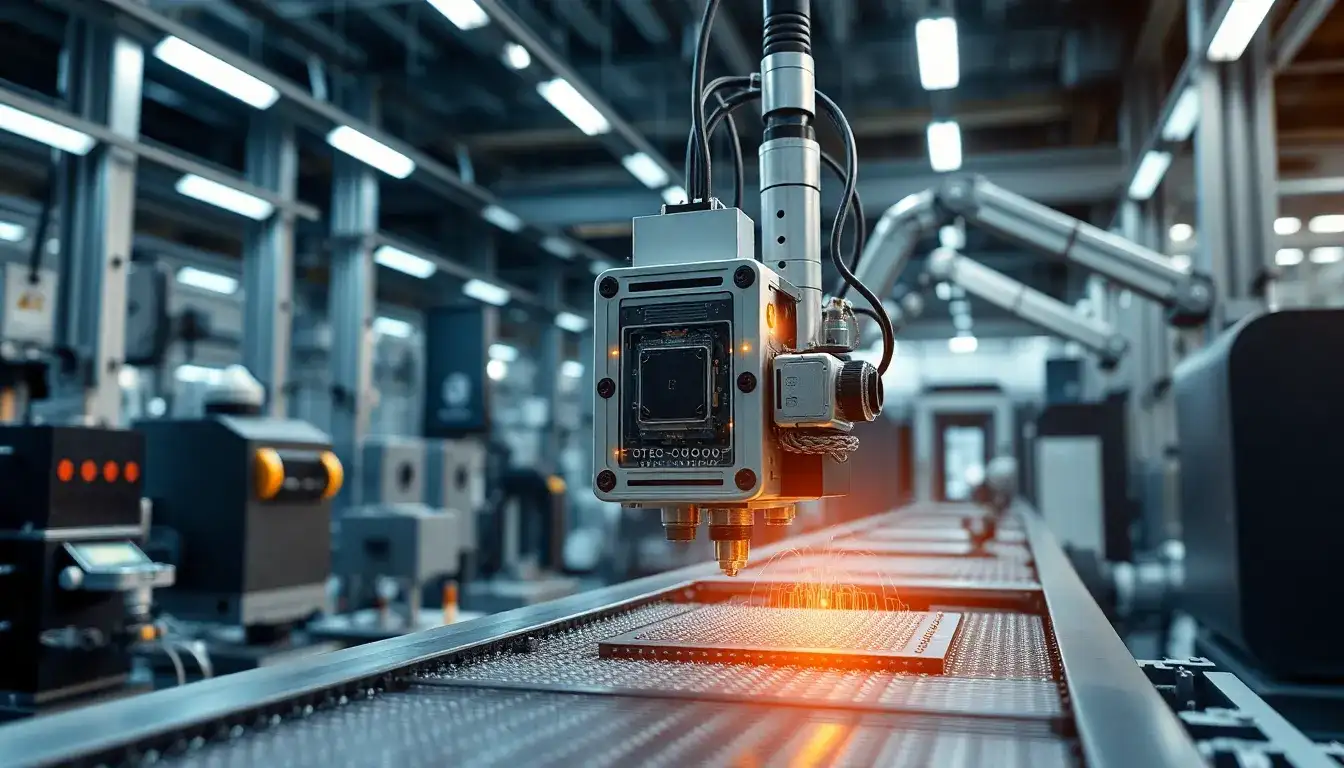

Artificial intelligence (AI) is fundamentally transforming the manufacturing landscape, particularly with the emergence of micro-level robots that enhance productivity and efficiency.

Recently, a report from Shanghai First Finance indicated that advancements in AI technologies are propelling a significant leap in manufacturing capabilities. The integration of precision measurement and the efficient handling of high-precision components is becoming increasingly rapid. The demand for micro-level robots that can operate with greater precision and speed is on the rise, as these robots offer superior efficiency compared to traditional manufacturing methods.

For instance, AI-driven manufacturing systems require a vast amount of data transmission and processing. The quality of the connections used in these systems is crucial. Any disruption in data transmission can lead to significant production losses. Therefore, efforts are being made to enhance connectivity for these micro-level robots, with a focus on maintaining high-quality standards.

According to the PLR Robotics division, the precision of these robots is exemplified in a specific project involving 16 micro-level robots, which require strict adherence to specifications, such as maintaining a wire diameter of 0.125mm and operating within a tolerance of 1 micron. This level of precision is essential for ensuring effective assembly and operation.

The report also highlighted that as micro-level robotics technology continues to evolve, these robots are expected to replace traditional manual labor in many aspects, enhancing overall productivity.

In terms of application, the FPC (Flexible Printed Circuit) technology is seeing widespread adoption across various industries. This technology supports the development of electronic products, communication devices, and electronic circuits, all of which require precise connections.

Looking ahead, micro-level robots are anticipated to replace human labor in specific production lines, driving advancements in manufacturing efficiency and reducing reliance on manual labor.

Moreover, the ongoing collaboration between Shenzhen-based companies and local manufacturers is paving the way for increased production capabilities. This partnership aims to enhance technological support and streamline operations.

Overall, the advancements in micro-level robotics and AI technologies are set to revolutionize the manufacturing sector, providing enhanced precision, efficiency, and productivity.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/advancements-in-ai-powered-micro-machine-technology-enhance-precision-and-efficiency-in-industry-automation/