1. The optimal material for solar thermal insulation barrels includes, but is not limited to, polyethylene foam, polyurethane foam, and fiberglass. Each material presents unique properties; however, polyurethane foam stands out due to its superior thermal resistance, lightweight nature, and versatility in application. This type of foam can provide a substantial barrier against heat loss, making it highly efficient in maintaining the temperature of the thermal fluid within the barrel. Its closed-cell structure minimizes air infiltration and water absorption, enhancing its durability and performance, particularly in extreme weather conditions. The insulation properties of polyurethane foam allow for greater energy efficiency, thereby reducing energy costs and enhancing the overall effectiveness of solar thermal systems. Furthermore, these barrels fabricated from this material exhibit excellent mechanical strength and longevity compared to other insulating materials. Therefore, for optimal performance and efficiency in solar thermal applications, polyurethane foam emerges as the leading choice among insulation materials.

1. UNDERSTANDING SOLAR THERMAL INSULATION

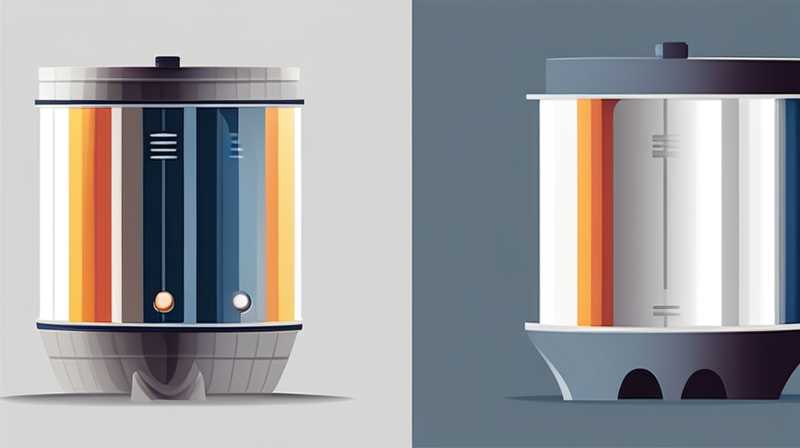

Solar thermal systems harness sunlight to produce thermal energy. This energy is predominantly utilized for heating water, thereby necessitating efficient insulation solutions. Insulation plays a pivotal role in any solar thermal system, influencing its efficiency by reducing heat loss. The choice of material significantly impacts the performance and longevity of the solar thermal insulation barrel. Different insulating materials offer various benefits and drawbacks. To maximize energy capture and retention, selecting the appropriate insulation material is essential.

When evaluating insulation materials, it is vital to consider aspects such as thermal conductivity, durability, weight, and environmental impact. Thermal conductivity determines how well the material prevents heat transfer, while durability ensures that the insulation maintains its efficiency over time. Materials like polyethylene foam, polyurethane foam, and fiberglass are competing options that possess unique features suitable for various applications. It is crucial to weigh these characteristics against the specific requirements of the installation to achieve optimal results.

2. TYPES OF INSULATION MATERIALS

POLYETHYLENE FOAM

Polyethylene foam has gained popularity within the solar thermal industry due to its unique characteristics. As a lightweight material, it provides excellent insulation performance without adding significant weight to the system. It effectively minimizes heat transfer and serves as a moisture barrier, making it an ideal choice for outdoor applications. Additionally, polyethylene foam is resistant to chemical decomposition, corrosion, and environmental exposure, enhancing its longevity.

Another advantage of polyethylene foam is its closed-cell structure, which further improves insulation performance. The individual cells trap air, reducing conduction and convection. While it is a cost-effective option, its thermal resistance may not match that of polyurethane foam, making it less suitable for applications requiring the utmost energy retention. Moreover, polyethylene is versatile and can be produced in various shapes, allowing for customized applications. While it may not be the best option for extreme temperature retention, it serves well in many standard solar thermal setups.

POLYURETHANE FOAM

When comparing insulation materials, polyurethane foam stands at the forefront due to its remarkable thermal performance and lightweight properties. It is formulated with a variety of densities and configurations, allowing it to cater to numerous applications, including solar thermal insulation. Its structure is mainly composed of closed cells that effectively trap air, providing superior thermal resistance compared to most alternatives. As a result, it minimizes energy losses, enhancing the efficiency of solar thermal systems.

The flexibility of polyurethane foam allows for easy application in various settings, whether it be cylindrical barrels or other complex shapes. Furthermore, it is often sprayed or injected into the desired areas, ensuring complete coverage and minimizing potential gaps or voids. This form of insulation also contributes to energy savings, which often results in a quick return on investment—by reducing heating costs associated with traditional systems. Not only does polyurethane foam yield excellent thermal performance, but it also exhibits stability in fluctuating environmental conditions, ensuring long-term insulation efficiency.

FIBERGLASS

Fiberglass has a longstanding history in insulation applications due to its versatility and thermal resistance capabilities. Made from glass fibers, this material is known for its excellent non-combustible properties. When employed in solar thermal insulation systems, fiberglass establishes an effective barrier against heat loss, ensuring that the heated fluids retain their temperatures for extended durations. However, its performance can heavily depend on the installation method and environmental exposure.

One notable characteristic of fiberglass is its ability to withstand high temperatures without losing insulating capacity. This allows it to perform effectively in various conditions. However, fiberglass insulation requires careful handling and installation. The loose fibers can pose health risks if not managed properly. Although it is a durable and effective material, its application can be more labor-intensive than that of foam materials, potentially increasing the overall project cost and timeline. Thus, while fiberglass serves as a competent insulation choice, it might not always be the best option, considering other materials are available that can offer similar or superior performance with easier installation processes.

3. ENVIRONMENTAL IMPACT AND SUSTAINABILITY

The selection of insulation material extends beyond mere performance metrics; it encompasses environmental responsibility as well. When choosing barrels for solar thermal insulation, it is paramount to consider the ecological footprint associated with each insulation type. Polyurethane foam, despite its impressive thermal resistance, has been scrutinized for its production process, which involves the use of chemicals that may contribute to ozone depletion. Additionally, the end-of-life disposal of polyurethane products needs consideration, as certain species of polyurethane foam can be challenging to recycle.

Conversely, polyethylene foam benefits from a relatively lower environmental impact as it is recyclable and doesn’t produce harmful emissions during its production. This makes it a relatively more sustainable option, especially when weighed against polyurethane. While polyethylene may not outperform polyurethane in terms of thermal resistance, it does provide a responsible choice for environmentally conscious consumers. Fiberglass, despite being durable, involves a manufacturing process that may produce particulate emissions; however, it remains largely inert when appropriately handled and installed, minimizing residual environmental implications.

Sustainability can also be promoted through proper maintenance of these insulation products. Regular checks to ensure no damage has occurred prolong the life of insulation. By committing to proper maintenance and selecting an appropriate insulation material, solar thermal systems can maintain efficiency long-term while minimizing environmental detriment.

4. ECONOMIC CONSIDERATIONS

Throughout solar thermal insulation material discussions, costs play a significant role. The financial aspect ranges widely among available materials, particularly when considering initial investments, maintenance, and operational costs. Polyurethane foam often incurs a higher upfront cost due to its advanced manufacturing process and superior performance characteristics. Nevertheless, its energy efficiency can offset these initial expenditures by reducing operation costs, making it a cost-effective solution in the long run.

In contrast, polyethylene foam presents itself as a budget-friendly alternative. While the initial costs may be lower, its energy retention capability can result in increased operational expenses, particularly in environments with significantly fluctuating temperatures. Consequently, while its affordability may be appealing, long-term financial repercussions should be thoroughly analyzed.

With fiberglass, up-front costs can vary depending on the type and installation method selected. Due to its installation complexity, labor charges could rise, impacting the overall budget. Potential health implications might necessitate precautions, adding to the total expenses incurred. Therefore, while fiberglass might serve as a viable solution, it warrants careful financial analysis to align projected operational costs with budgetary constraints.

FAQs

WHAT IS SOLAR THERMAL INSULATION?

Solar thermal insulation refers to materials specifically designed to minimize heat loss in solar thermal systems, enhancing energy efficiency. These materials encase the pipes or vessels that transport heated fluids, preventing excessive temperature drops. Insulation assists solar thermal energy systems, such as rooftop panels and heat storage tanks, in maintaining optimal thermal performance. Various materials, including polyethylene foam, polyurethane foam, and fiberglass, are employed in these applications. Each material demonstrates unique characteristics; the decision on which to utilize depends on specific project requirements, including thermal retention capacity, environmental conditions, and budget constraints.

HOW DOES POLYURETHANE FOAM COMPARE TO OTHER INSULATION MATERIALS?

Polyurethane foam stands out among insulation materials due to its superior thermal resistance and lightweight nature. Its closed-cell structure provides exceptional performance in preventing heat transfer, thereby enhancing energy efficiency in solar thermal systems. In contrast, polyethylene foam offers a more cost-effective solution, although it may not provide the same level of insulation effectiveness as polyurethane. Comparatively, fiberglass performs well in high-temperature environments; however, its initial installation can be more intensive and expensive. When assessing insulation materials, it is essential to consider varying characteristics such as thermal conductivity, weight, environmental impact, and installation methods, among others, to choose the most suitable option for each unique application.

WHAT FACTORS SHOULD BE CONSIDERED WHEN CHOOSING INSULATION MATERIALS?

When selecting insulation materials for solar thermal applications, several critical factors warrant consideration. Thermal conductivity ranks highly, influencing how well the material retains heat. Durability is also essential to ensure the insulation retains its performance over the long term while withstanding environmental conditions. Cost is another significant aspect; budget constraints require finding equilibrium between initial investment, operational efficiency, and service life. The environmental impact of insulation materials should not be overlooked; sustainable options contribute positively to reduced ecological footprints. Lastly, application ease can affect installation timelines and labor costs. Carefully evaluating these factors aids in arriving at an informed and beneficial insulation material decision.

Selecting the most suitable insulation material for solar thermal applications is a multifaceted decision that can significantly impact the system’s efficiency, longevity, and overall performance. Opting for the optimal material requires careful evaluation of numerous factors including thermal conductivity, durability, and environmental impact. Polystyrene foam, polyurethane foam, and fiberglass exemplify the available choices in today’s market, each possessing unique strengths and weaknesses that cater to different installation contexts. As energy efficiency remains a priority in the renewable energy sector, pursuing the efficiencies of solar thermal insulation becomes increasingly paramount, driving the need for continued innovation and optimization in material science. As technology evolves, new materials and techniques may emerge, further refining how we approach solar thermal insulation. The choice made not only influences immediate financial trends and performance metrics but also resonates with broader environmental implications as the world shifts toward sustainable energy solutions. Balancing the trade-offs inherent in these materials can eventually lead to more efficient solar thermal systems that contribute meaningfully to energy conservation efforts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/which-material-is-better-for-solar-thermal-insulation-barrel/