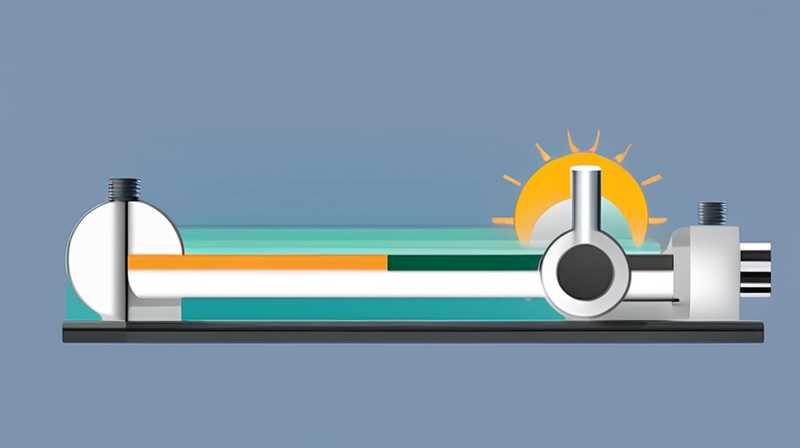

What type of solar insulation pipe

1. SOLAR INSULATION PIPE METHODS, Various materials impact heat retention, Performance and durability vary based on environmental conditions, Proper selection optimizes energy efficiency.

Solar insulation pipes play a pivotal role in harnessing and maintaining solar energy, particularly in systems focused on heating. Among the most critical aspects of their functionality is the insulation material used, which directly affects the overall efficiency of solar thermal systems. 1. Different types of insulation materials are available, each exhibiting unique characteristics. For instance, polyurethane foam is renowned for its excellent thermal resistance, which minimizes energy loss. 2. The selection process must involve a comprehensive evaluation of specific system requirements, including regional climate and operational temperatures.

Furthermore, one must consider the installation environment, as factors like humidity and UV exposure can compromise the integrity of the insulation. Moreover, various standards and certifications exist to guide consumers in selecting the right type of insulation pipe, ensuring safety and performance. For optimal results, engaging with professionals who can assess and recommend suitable options tailored to specific circumstances is highly advisable.

1. INSULATION MATERIALS IN SOLAR PIPES

When examining the materials utilized in solar insulation pipes, several key players dominate the market. Polyurethane foam, expanded polystyrene (EPS), and mineral wool are among the most popular choices, each presenting distinct advantages and disadvantages.

Polyurethane foam is primarily favored for its high insulation performance. Its low thermal conductivity translates to superior heat retention, ultimately enhancing the efficiency of solar heating systems. The application process of polyurethane foam typically involves either spray or rigid board methods, both of which allow for a snug fit around pipes, reducing gaps where heat could escape. This material is inherently resistant to moisture, making it well-suited for outdoor applications, where environmental exposure is a concern. Moreover, the longevity of polyurethane means that fewer replacements are needed over time, offering long-term cost savings despite a higher initial investment. The downside, however, is that it may require fire retardants, which could complicate installation.

Expanded polystyrene (EPS) serves as a viable alternative to polyurethane, often at a lower cost. Its lightweight nature allows for easy transportation and installation. While the insulation capabilities of EPS are respectable, they do not quite match that of polyurethane. Nonetheless, its cost-effectiveness makes it an attractive option for residential applications where budget constraints are significant. One downside of EPS is its vulnerability to water, which could lead to degradation if not properly shielded. Ensuring adequate protective measures can mitigate this risk, such as using waterproof barriers during installation.

Mineral wool, often termed rock wool or stone wool, is another insulation option. This material stands out due to its fire-resistant properties and natural resistance to moisture. Mineral wool is inorganic, which means it does not support mold growth, providing an additional layer of safety for users. While its thermal performance is sufficient for many applications, it does not reach the benchmarks set by polyurethane foam. That said, mineral wool is frequently selected in instances where fire safety is paramount, such as in commercial or industrial facilities.

2. OPTIMIZING PERFORMANCE THROUGH DESIGN

The design of solar insulation pipes also significantly influences their efficiency. Design variations can impact both the thermal performance and durability of the installed systems.

One essential design consideration is the thickness of the insulation. A thicker layer enhances thermal resistance, but it also adds weight and can complicate installation. Assessing the specific performance requirements of a project is vital in determining the optimal insulation thickness. In many cases, these calculations will rely on an analysis of the heat loss expected for the projected application and environment. Balancing insulation performance with practical considerations like space constraints and structural integrity will ultimately guide design choices.

Furthermore, the length and configuration of pipe runs also affect overall system efficiency. Shorter, direct runs help reduce thermal losses, while complex layouts introduce additional thermal bridges, potentially sacrificing efficiency. Optimizing the layout of piping systems in solar installations requires careful planning and sometimes even simulation analyses to predict where heat losses may occur. For larger systems, modular designs may help streamline installation and reduce time and effort expended during setup. Making informed decisions at this stage can significantly enhance long-term performance outcomes.

3. INSTALLATION BEST PRACTICES

Proper installation is crucial for ensuring the effectiveness of solar insulation pipe systems. Attention to detail during this phase can dictate the longevity and efficiency of the entire setup.

Qualified professionals should carry out installation. Their expertise aids in correctly fitting insulation materials and adhering to relevant codes and standards. Correct positioning of insulation around pipes prevents thermal bridging, where heat can be lost through joints or gaps between insulation pieces. Using high-quality adhesives and fastenings can further stabilize the installation, mitigating the risk of movement that could compromise the insulation effectiveness.

Additionally, attention must be given to the sealing of joints. Gaps in insulation impede energy storage capabilities, leading to decreased performance over time. Utilizing tape and caulk specifically designed for insulation helps in achieving a continuous insulation layer, effectively minimizing air infiltration. Regular site inspections during the installation phase can catch potential problems early on, ensuring a well-executed project that adheres closely to initial design specifications.

4. MAINTENANCE AND LONGEVITY

Ongoing maintenance is crucial for sustaining the performance of insulation pipes. Regular inspections can help identify wear and tear, moisture intrusion, or insulation deterioration that may affect system efficiency.

One key area to monitor revolves around moisture accumulation. Insulation materials like EPS, if not properly protected, can be subject to water damage, leading to thermal inefficiency and mold growth. Installing moisture barriers and ensuring proper drainage around installations can mitigate these risks, providing an additional line of defense for insulation.

Furthermore, scheduled evaluations of the entire solar system, including insulation pipes, can help in identifying any performance discrepancies. If the insulation system is observed to be underperforming, experts can suggest repairs or replacements as necessary. Proper allocation of resources towards maintenance ensures a more reliable return on investment, allowing systems to function efficiently and yield optimal energy results over their lifespan.

5. REGULATORY STANDARDS AND CERTIFICATIONS

Familiarization with the applicable standards and certifications is essential for anyone involved in the installation and maintenance of solar insulation pipes. Numerous national and international regulations serve to guide best practices and ensure safety for users.

Standards established by organizations such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) provide essential criteria for evaluating insulation materials. These specifications determine aspects like thermal resistance, flammability, and moisture absorption rates, which directly affect the performance of solar thermal systems. Compliance with established criteria not only benefits safety but also assures quality and reliability for users.

Furthermore, many regions require installations to meet specific building codes. These codes often dictate insulation material properties, installation techniques, and overall system performance. Failure to adhere to these regulations can result in both financial penalties and diminished effectiveness of solar systems. Consulting with local regulatory bodies and industry groups can provide clarity on the required standards, thereby ensuring that installations are both compliant and optimal for performance.

FAQS

WHAT IS THE BEST INSULATION MATERIAL FOR SOLAR PIPES?

The determination of the most suitable insulation material for solar pipes hinges on various factors, including thermal performance, environmental conditions, and budget considerations. Polyurethane foam typically tops the list due to its exceptional thermal resistance and moisture resistance. This material minimizes heat loss effectively, thereby optimizing energy efficiency in solar heating systems. For individuals or businesses operating under tighter budgets, expanded polystyrene (EPS) emerges as a practical alternative, albeit with slightly lower insulation property performance. Mineral wool also serves as a contender due to its inorganic nature and fire-resistant capabilities, making it suitable for applications where safety is paramount. Engaging professionals who can assess individual circumstances will help in identifying the best insulation material for specific applications.

HOW OFTEN SHOULD SOLAR INSULATION PIPES BE INSPECTED?

Inspection frequency for solar insulation pipes may vary based on installation environment and material specifications. However, in general, it’s advisable to conduct a thorough inspection annually. These inspections should focus on checking for moisture accumulation, physical damage, or any signs of thermal performance downturns. Regular evaluations are especially crucial for installations situated in harsh environments, such as areas prone to heavy rainfall, extreme temperatures, or intense UV exposure. Early detection of weaknesses or wear can prevent significant performance declines, enabling timely repairs or replacements that’ll ensure the longevity and efficiency of the entire solar heating system. Residents and property managers should also keep an eye out for any external factors that might impact insulation integrity.

CAN I REPLACE INSULATION ON EXISTING SOLAR PIPES?

Replacing insulation on existing solar pipes is indeed feasible and occasionally necessary to maintain optimal system performance. Before undertaking such a task, it’s vital to assess the condition of the current insulation and determine the reasons for its deterioration. Factors like moisture damage, wear and tear, or non-compliance with current standards may motivate a decision to replace insulation. When performing insulation replacement, it is essential to engage experienced professionals to execute the project correctly, thus mitigating risks associated with improper handling. Selecting appropriate materials during replacement will ensure the system operates efficiently for years to come.

Adhering to best practices for solar insulation pipe systems not only enhances efficiency but also ensures longevity and reliability for users. By evaluating insulation material choices, ensuring optimal design, maintaining proper installation techniques, and following through on regular maintenance checks, solar thermal systems can thrive in diverse environments. The continuing evolution of technologies and materials available in the solar insulation sector promises even greater efficiency gains in the near future. As professionals refine best installation practices and align with regulatory standards, users stand to benefit significantly from lower energy costs and reduced environmental impacts. Investing time and resources in understanding the intricacies of different insulation options, coupled with preventive measures, can secure a solid foundation for the sustainable use of solar energy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-type-of-solar-insulation-pipe/